Introduction

Learn about the properties and applications of 19-W-4 steel grating, a versatile and durable product used in various industries such as construction, transportation, and power plants. Discover its benefits, such as corrosion resistance and load capacity, and see how it can be used in different settings.

Unlock the full potential of 19-W-4 steel grating by reading this informative article. Discover its various uses, from construction to transportation, and learn how its strength and durability can benefit your industry or project.

1. Basics of 19-W-4 steel grating

19-W-4 steel grating is a welded, light-duty carbon steel bar grating that is widely used and readily available. It is available in widths up to 3 feet and lengths up to 24 feet and comes in bar thicknesses of 1 inch by 3/16 inch and 1 inch by 1/8 inch.

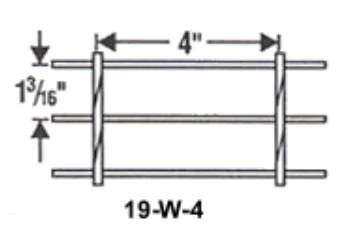

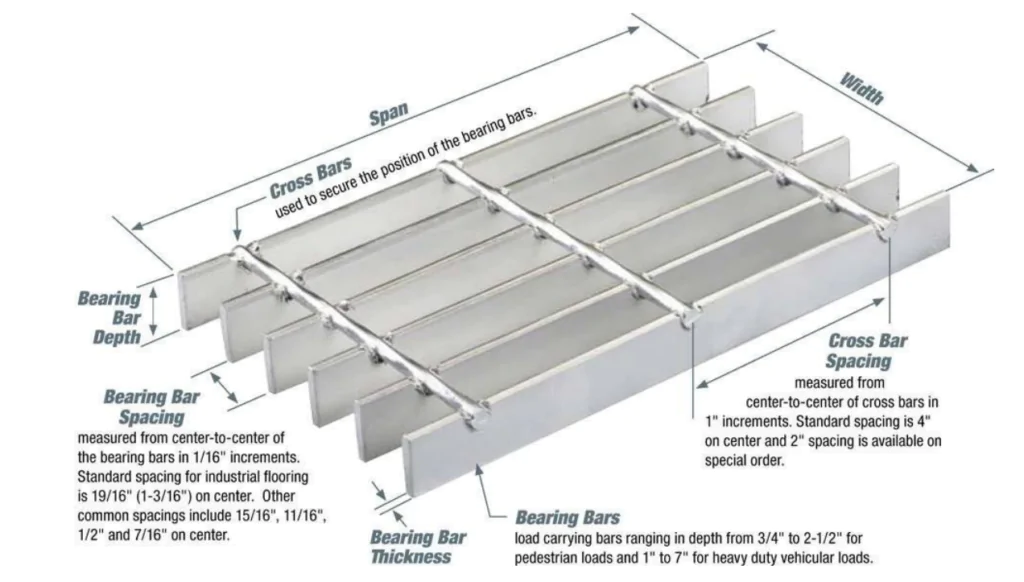

The grating is manufactured using a resistance-weld process, in which the cross bars are fused to the bearing bars to form a permanent joint. The bearing bars are 1-3/16 inches apart, and the cross bars are 4 inches apart.

The grating is available in smooth, serrated, and non-slip surfaces, and finishes include mill, black primer, and hot-dipped galvanized. It is commonly used in areas with light traffic, such as sidewalks, walkways, and mezzanine levels.

In contrast, 19W4 Heavy Duty Welded Steel Bar Grating is designed for areas with heavy traffic, such as H-10, H-20, automobiles, and forklifts. It is available in widths of 2 and 3 feet and lengths up to 24 feet. The grating is made with bearing bar sizes ranging from 1 to 6 inches in depth and thicknesses of 1/4 inch, 5/16 inch, 3/8 inch, and 1/2 inch.

It is spaced 1-3/16 inches apart for the bearing bars and 4 inches for the cross rods/bars. Applications include vehicular trenches, vehicular sump pits, forklift traffic, airfields, bridges, plant floors, loading docks, and other areas with heavy truck or forklift traffic. Surface options are smooth or serrated. Available finishes include mill, painted black, or hot dipped galvanized.

19-w-4 bar grating is also known as welded steel bar grating and is considered one of the most robust and most durable metal grating products. It is made from mild carbon steel or stainless steel and is ideal for a wide range of applications due to its strength and durability.

The grating is fully recyclable and is available in a wide range of surface options, including smooth or serrated. Available finishes include mill, painted black, or hot dipped galvanized. Due to its high performance and stability, 19-w-4 bar grating has become one of the market’s most popular types of grating.

2. Structure of 19-W-4 steel grating

The structure of 19-W-4 steel grating is made up of two main components: bearing bars and cross bars. The bearing bars, also known as load-bearing bars, are the horizontal bars that support the weight of the load. They are available in various thicknesses, depths, and spacings to suit different applications and loading requirements.

The cross bars, also known as transverse bars, are the vertical bars that connect the bearing bars. They are available in different diameters, shapes (round or twisted), and spacing. They provide additional stability to the grating and prevent the bearing bars from spreading apart under load.

- Cross bars are available in Dia. 5mm, 6mm, 8mm (Round bar) / 55mm, 66mm, 88mm (Twist bar)

- Cross bar spacing range from 40, 50, 60, 65, 76, 100, 101.6, 120, 130mm, etc.

- Bearing bars are available in 205, 253, 254, 255, 303, 304, 305, 323, 325, 405, 504… 75*8mm, etc.

- Bearing bar spacing range from 20, 25, 30, 32.5, 34.3, 40, 50, 60, 62, and 65mm.

19-W-4 steel grating is available in various types to suit applications, including smooth top or serrated (anti-slip) grating. As a leading manufacturer and fabricator of electro-forge welded steel grating in China, they supply a variety of sizes for shipment in panels or other specifications.

3. The benefits of gratings

- Durability: 19-W-4 steel grating is made from mild carbon steel or stainless steel, which makes it extremely strong and durable, able to withstand heavy loads and regular use.

- Load capacity: With the capability of bearing heavy loads and traffic, 19-W-4 steel grating is well-suited for use in areas with heavy foot or vehicular traffic, such as loading docks, bridges, and airfields.

- Low maintenance: The grating requires very little maintenance, making it a cost-effective solution for any business or organization.

- Corrosion resistance: The grating is available with a hot-dipped galvanized finish, which provides a layer of protection against rust and corrosion, making it suitable for use in harsh environments.

- Safety: The serrated surface provides a non-slip surface which can help prevent accidents and injuries.

- Versatility: The grating is available in a wide range of sizes and thicknesses, making it suitable for various applications and environments.

- Easy installation: The grating can be easily installed and cut to size if necessary, making it a convenient solution for any project.

- Recyclable: The grating is fully recyclable, making it an environmentally friendly solution.

4. What are the applications

- Industrial flooring: 19-W-4 steel grating is commonly used as a flooring surface in factories, warehouses, and power plants.

- Catwalks and mezzanines: The grating is well-suited for use as a walkway or platform in industrial settings.

- Decking: The grating is often used as a decking surface for bridges and other structures.

- Stair treads: The grating can be used as stair treads in industrial and commercial settings.

- Fencing: The grating can be used as fencing in industrial settings to provide a durable barrier.

- Ramps: The grating can be used as a ramp surface for heavy equipment and vehicles.

- Docks: The grating is well-suited for use as a surface on docks and loading areas.

- Trench covers: The grating can be used as a cover for trenches and drainage pits.

- Maintenance platforms: The grating can be used as a surface for maintenance platforms in industrial settings.

- Wash racks: The grating can be used as a surface for wash racks in industrial settings.

- Ventilation screens: The grating can be used as a ventilation screen in industrial settings.

- Storage racks: The grating can be used as a surface for storage racks in industrial settings.

- Window and machinery guards: The grating can be used as a guard for windows and machinery in industrial settings.

- Boiler equipment and heavy equipment areas: The grating can be used as a surface in boiler equipment and heavy equipment areas in industrial settings.

- Stainless steel grating: Stainless steel grating can be used in areas with environmental challenges, such as chemical plants and food processing facilities.

Conclusion

In conclusion, this article has highlighted the numerous benefits and diverse applications of 19-W-4 steel grating. This versatile and durable product can bring strength and stability to any project, from industrial flooring to trench covers. Implementing the tips outlined in this article can help you make the most of 19-W-4 steel grating in your industry or project.