Introduction to Standard Steel gratings

General Introduction to Standard Steel Grating

Standard steel grating commonly referred to as bar grating is one of the most widely used products in the construction and manufacturing industries.

Bar grating is available in a wide variety of materials, including aluminum, carbon steel, galvanized steel, and stainless steel. It is also available in a variety of heights, thicknesses, and spacing to suit any application.

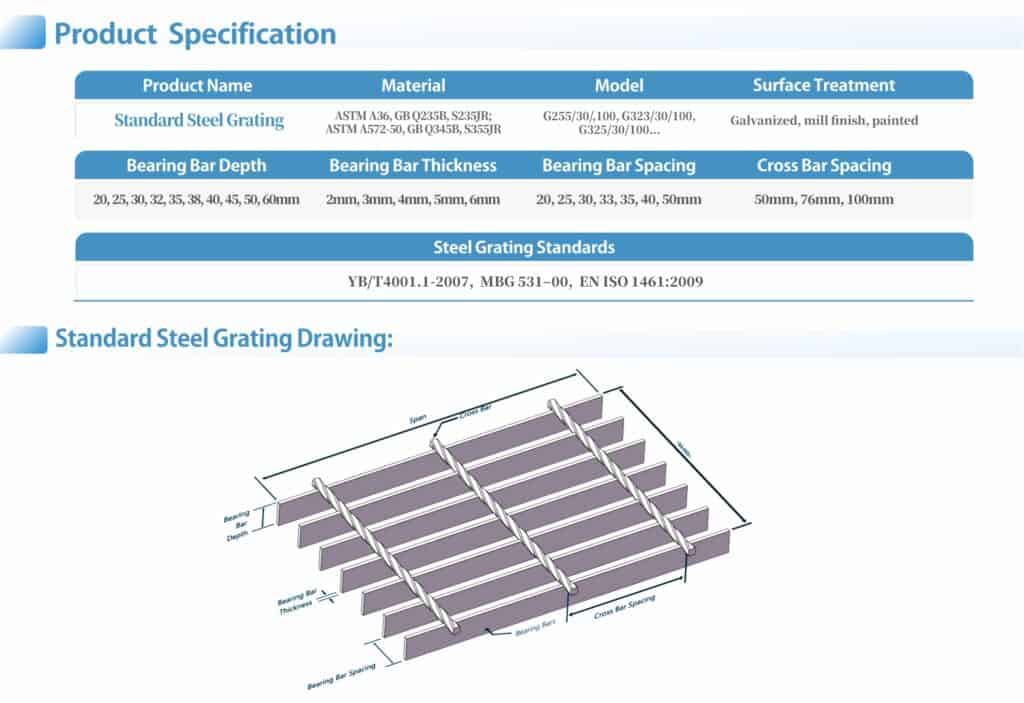

Standard Steel Grating Specification

Our hot selling Standard Steel Gratings

Grating is the best place to go for all your metal grating needs. We have over 15 years of experience and our team will be happy help you with any welding, shearing or cutting project that comes up!

Plain standard steel gratings

Serrated standard steel gratings

Checkered standard steel gratings

Why choose Standard Steel Gratings from us ?

All of our standard steel grating products are available in a variety of materials, finishes, heights, thicknesses, and spacing. If you can’t find the exact product you need, please contact us. We will be happy to create a custom solution for you.

Chinagaring.com is your one-stop source for all your standard steel grating needs. Contact us today for more information on our products and services.

- 19 years of manufacturing and exporting experience for standard steel grating

- Our products have been approved by SGS, ISO9001, etc.

- We can provide custom solutions for your specific project requirements

- We offer quality products at competitive prices

Types of Standard Steel Gratings

When it comes to standard steel gratings, there are three main types: plain, serrated, and checkered. Each type of grating has its own unique set of benefits and applications.

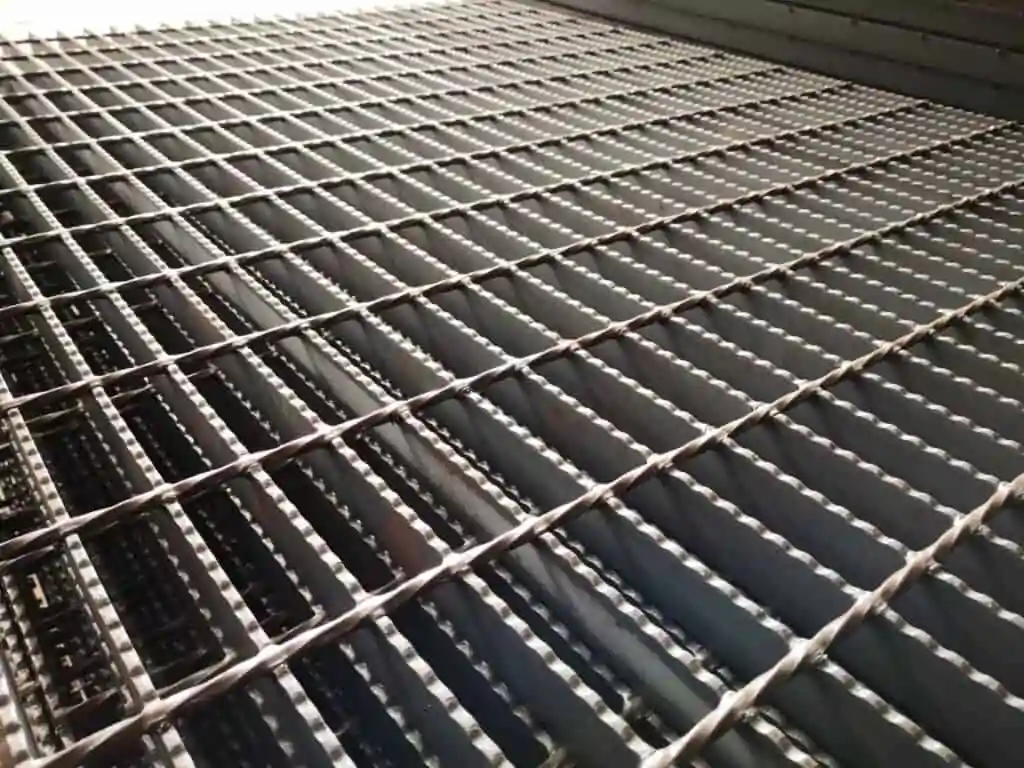

Plain standard steel gratings

Plain standard steel gratings are the most popular type of grating. They are made of standard steel, which is a type of metal that is strong and durable. Plain standard steel gratings are available in a variety of sizes and thicknesses, making them versatile for use in a variety of applications. Some common uses for plain standard steel gratings include walkways, catwalks, and mezzanines.

Plain standard steel gratings

Plain standard steel gratings are the most popular type of grating. They are made of standard steel, which is a type of metal that is strong and durable. Plain standard steel gratings are available in a variety of sizes and thicknesses, making them versatile for use in a variety of applications. Some common uses for plain standard steel gratings include walkways, catwalks, and mezzanines.

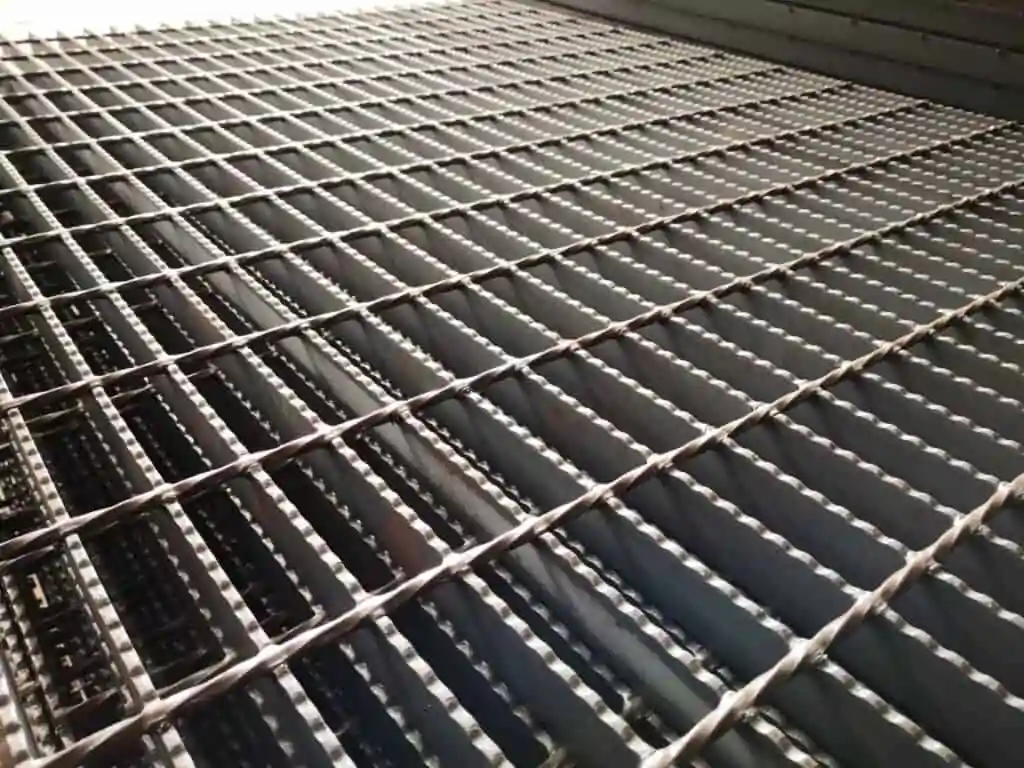

Serrated standard steel gratings

Serrated standard steel gratings are also popular. They offer a slip-resistant surface that is perfect for wet or oily environments. Serrated gratings are available in a variety of sizes and thicknesses, making them versatile for use in a variety of applications. Some common uses for serrated standard steel gratings include walkways, catwalks, and mezzanines.

Checkered standard steel gratings

Checked standard steel gratings are the third type of standard steel grating. They offer a high level of traction and are perfect for use in applications where there is a lot of foot traffic. Checked gratings are available in a variety of sizes and thicknesses, making them versatile for use in a variety of applications. Some common uses for checked standard steel gratings include walkways, catwalks, and mezzanines.

The Process Flow for Standard Steel Gratings

Step 1: Design Consultation(1-2 days)

Before the production process begins, our team of experts will consult with you to determine the best design for your project. We take into account the intended use of the final product, the dimensions and weight of the load, the environment in which it will be used, and any other relevant factors. This ensures that your steel gratings will be up to the task and will last for years to come.

Step 2:Preparing raw materials(1-2 days)

The quality of the raw materials used is crucial to the quality of the final product. We only use the best materials available to create our steel gratings, ensuring that your product will meet or exceed your expectations. Also, all of our materials are sourced from sustainable and environmentally friendly suppliers.

Step 3:Welding of steel gratings(5 days)

Once the design is finalized and the raw materials have been sourced, the manufacturing process can begin. The first step is pressure welding, in which panels are welded together to create the desired shape. This is done using a high-pressure welding machine that creates a strong, stable bond between the panels.

Step 4:Press-locking of steel gratings(3 days)

After the welding process is complete, the steel gratings are moved to the products workshop for finishing. Here, any necessary cuts or holes are made, and the gratings are given a final inspection to ensure that they meet our high standards. Once they have passed inspection, the gratings are ready to be shipped to our clients.

Step 5:Step 4:Products Finishing(3 days)

After the welding process is complete, the steel gratings are moved to the products workshop for finishing. Here, any necessary cuts or holes are made, and the gratings are given a final inspection to ensure that they meet our high standards. Once they have passed inspection, the gratings are ready to be shipped to our clients.

Step 6:Quality Inspection(1-2 days)

After the welding process is complete, the steel gratings are moved to the products workshop for finishing. Here, any necessary cuts or holes are made, and the gratings are given a final inspection to ensure that they meet our high standards. Once they have passed inspection, the gratings are ready to be shipped to our clients.

Step 7:Packaging(1 days)

To ensure that the products are not damaged during transport, we use high-quality packing materials.the packing of steel gratings requires special care and attention. Be sure to wrap each grate in a layer of plastic film, place them in a box or crate, and fill the gaps between the grates with packing material such as styrofoam peanuts or bubble wrap. Seal the box or crate with tape and label it with the contents and the date. These packing tips will help to ensure that your steel grates are protected from rust and corrosion during storage or transportation.

The advantage of our Stainless Steel Gratings

Strong and durable

Easy to install

Low maintenance

Cost-effective

Quality Certification of Standard Steel Gratings

The application of Standard Steel Gratings

Standard steel grating can be used in a variety of applications, such as:

- Walkways -It can be used in the walkways to provide a safe and slip-resistant surface.

- Work platforms -Work platforms can be built using grating panels.

- Mezzanines -Grating panels can be used to create mezzanines.

- Stair treads -Stair treads can be made of grating panels.

- Drain covers -Grating panels can be used to create drain covers.

- Machinery guards -Machinery guards can be made from grating panels.

FAQs for Standard Steel Gratings

The standard steel grating is a type of metal grating that is made from steel. It has a variety of applications, including in construction and manufacturing.

There are many benefits to using a standard steel grating. Some of these benefits include its durability, its strength, and its ability to resist corrosion. Additionally, standard steel gratings are often used in construction because they can be easily installed and do not require special tools or equipment.

Some of the drawbacks to using a standard steel grating include its weight and its cost. Additionally, because it is made from steel, it is susceptible to rust and corrosion. Finally, if not installed properly, a standard steel grating can be dangerous.

When choosing a standard steel grating, it is important to consider the application in which it will be used. Additionally, you should take into account the size, shape, and weight of the grating. Finally, you should also consider the cost of the grating and its durability.

Contact Us

Get a Quotes

SUNJ Grating is the best place to go if you need metal gratings! We have over 15 years of experience and our team will be happy to help with any steel gratings needs.

- Yanxin Road,Wuxi,Jiangsu,China

- sales@chinagratings.com

- +86-15052255397