Serrated Steel Bar Grating Manufacturer

- Fine and Reliable Serrated Steel Bar Grating

- Trustworthy Customer Support

- Available at an Affordable Cost

- Speedy International Delivery

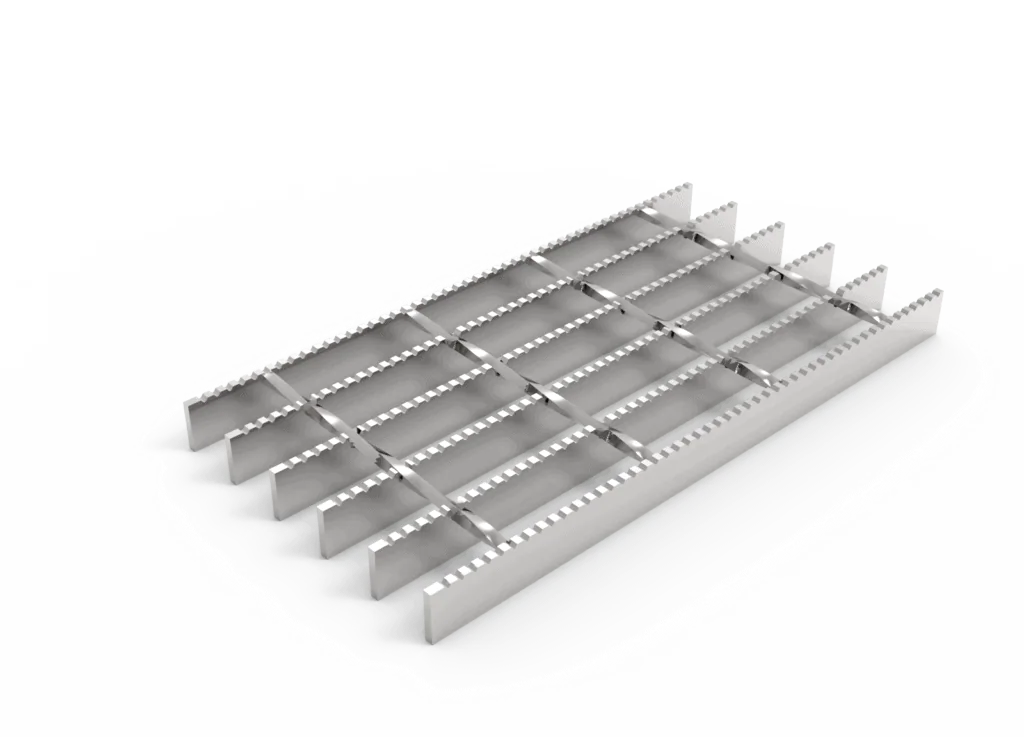

General Introduction to Serrated Steel Bar Gratings

Serrated steel grating is extensively found in damp, slippery areas that require anti-slip performance; for example, they are utilized in industrial, residential, and corporate structures as platforms, stair treads, etc.

Serrated steel bar grating can be manufactured using various materials, especially stainless steel and low carbon steel. It is made by welding, press-locking, swage-locking, or riveting bearing bars and cross bars at certain distances to produce a high-strength grid-like structure.

This is why it has tensile endurance and an excellent load-carrying capacity. It is also non-slip, anti-corrosion, with excellent safety capability. Plus does not retain rain, snow, or pollution and has high durability.

We offer four types of steel grating: Welded, swage-locked, press-locked, and riveted serrated steel gratings. Besides, we also offer customization services to help you design a custom serrated steel bar grating per your application needs.

Our Hot Selling Serrated Steel Bar Grating

Welded serrated steel grating

Swage-locked serrated steel grating

Press-locked serrated steel grating

Why choose Serrated Steel Bar Grating from ChinaGrating.com?

You get dependable and long-lasting gratings when you buy Serrated Steel Grating from Chinagaring.Com.

Our serrated steel gratings are composed of high-quality materials such as aluminum, stainless steel, and low-carbon steel. They are used for wide array of residential, industrial and commercial settings, such as floors, staircases, fences, and platforms.

Our serrated steel bar grating is an excellent choice for any application with a critical need for endurance and sturdiness. Plus, it will not rust or corrode with time, as other metals may.

- We have the most reasonable prices and exceptional wholesale rates.

- Our goods are long-lasting, safe, and of excellent quality since they meet global standards.

- We provide extensive product customization to fit your individual requirements.

- We have a highly skilled workforce, a modern production facility, and over 15 years of expertise designing, modifying, and producing serrated steel gratings.

Types of Serrated Steel Bar Gratings

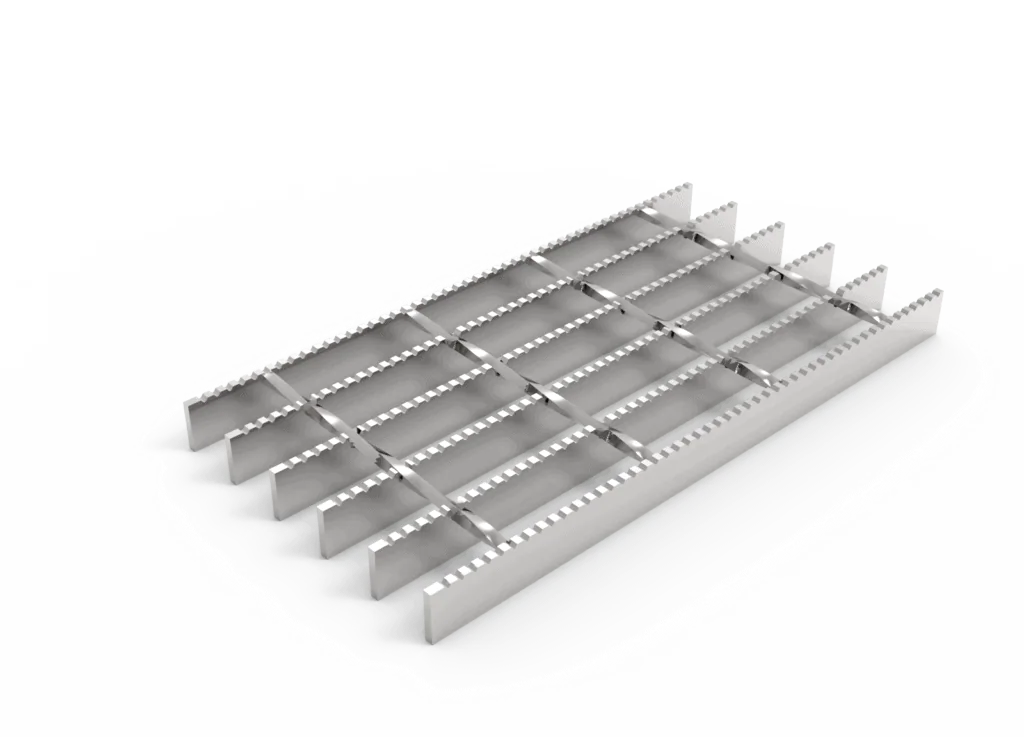

Welded Serrated Steel Bar Grating

Welded gratings are strong grids made of bearing and cross bars. These steel bearing bars are neither chipped nor pierced. In contrast to press-locked gratings, the welded gratings have stretched and twisted steel cross bars that are welded to the serrated bearing bars in a perpendicular direction. This is to ensure the sturdiness of the serrated steel bar grating.

The opening space can also be reduced to keep things from slipping through.

Welded serrated steel bar gratings are mostly made using low carbon steel or stainless steel. It is surface treated by the processes such as hot-dip galvanizing, mill finishing, and paint or powder coating.

Welded serrated steel doesn’t bend even in the harshest conditions. Due to the inclusion of twisted cross bars, it also provides an anti-slip effect. It is so stable that even in its ungalvanized form, it doesn’t lose its steadiness.

It can be used for platforms, stair treads, shelves, floors, and ceilings of any commercial or residential area.

Apart from the material and surface treatment, the bearing bar height and thickness, along with the mesh size of welded serrated steel bar gratings, can also be altered to meet specific application needs.

Swage-locked Serrated Steel Grating

The swage-locked serrated steel grating can be made up of aluminum or stainless steel. The cross bars are put through already punched perforations in the bearing bars, after which they are hydraulically swaged under lots of pressure to set them securely.

Serrated Swage-locked steel bar gratings are classified into three types: serrated rectangular bars, serrated I bars, and serrated T bars. The most common kind is Serrated I bar swage-locked grating, which is lightweight and less expensive than rectangular bar swage-locked grating.

This type of steel grating can be used in stair treads, floors, platforms and bride decking, etc., in the industrial sector. These gratings can be used as tread gratings, floors, platforms, or decks in the commercial sector.

It can be the ultimate choice in all these areas due to its anti-corrosive properties, immense strength, rigidity, fast speed, and easy installation.

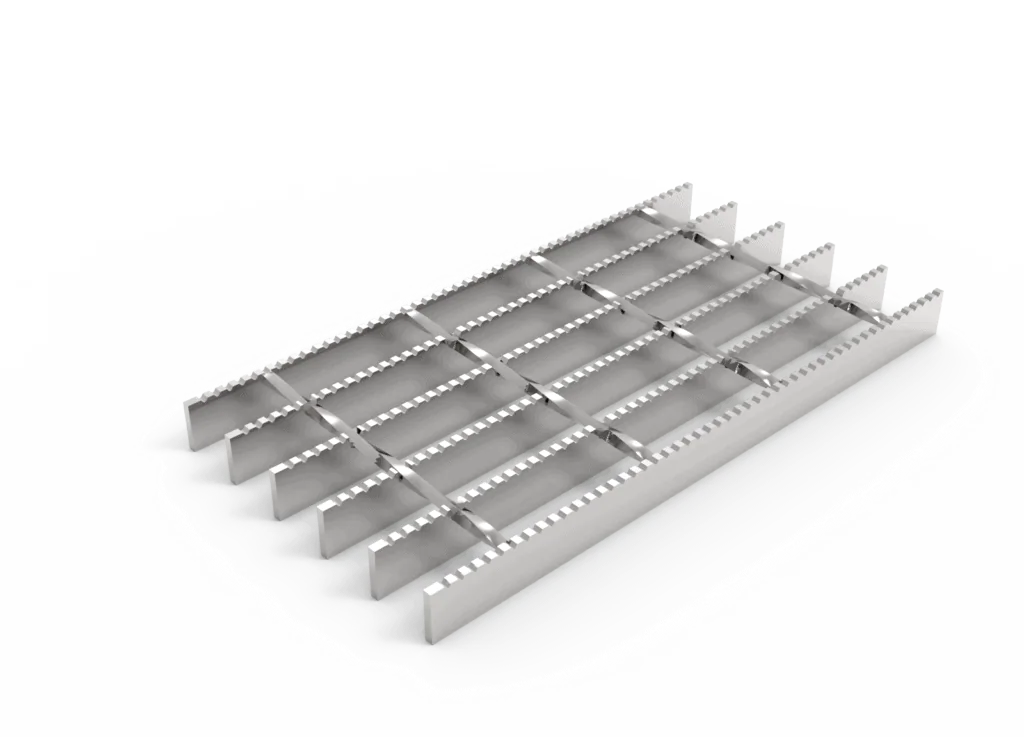

Press-locked Serrated Steel Grating

The press-locked serrated steel grating can also be called pressure-locked serrated steel grating since it is manufactured by applying tremendous hydraulic pressure. This pressure connects the two close-tolerance slotted bars, firmly securing them in place.

These press-locked serrated steel bars may be hot-dip galvanized and painted or powder coated.

These press-locked serrated steel bars have several advantages, such as their non-slip and anti-corrosive properties. They are also lightweight but extremely sturdy. Their strength is the most common use of stair treads, security screens, and bridges.

They also have a long lifecycle and are also easy to install or remove. Their attractive appearance is an eye-turner, but the best part is that this appearance isn’t easy to deform.

Riveted Serrated Steel Grating

Riveted serrated gratings are heavy-duty steel bar gratings with more load-bearing capacity than press-locked, welded, or swage-locked serrated steel bar gratings with the same span, thickness, and depth of grating.

It comprises bearing bars and crimp bars that are fastened together using rivets.

Riveted gratings are available in a number of materials, including aluminum, carbon steel, and stainless steel.

Riveted gratings are used in various applications, including industrial and commercial settings.

For applications with high corrosion resistance, the serrated carbon steel bar grating is best as it can undergo surface treatments like galvanization or paint to enhance its corrosion resistance further.

Besides, aluminum serrated steel bar grating can also be helpful for applications where good resistance to corrosion along with a lightweight structure is required.

In contrast, stainless steel serrated steel bar grating is most suitable for harsh environments, where extra resistance to acid and alkali is required.

The Process Flow for Serrated Steel Bar Grating

Here at China Gratings, we take every step carefully to develop the finest quality of Serrated Steel Grating.

Our devoted and professionally trained team of specialists, together with our cutting-edge process flow, allows us to develop the most robust, sturdy, and visually beautiful serrated steel grating that efficiently meets the usage demands of our customers.

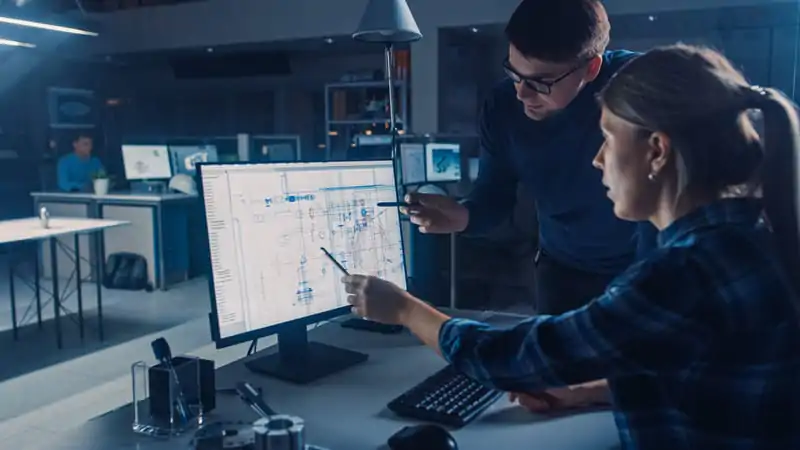

1. Design Development:

Our design team has a thorough chat with the customer to identify their needs and propose the ideal design for their usage.

Features such as the dimension, bearing bar spacing, bearing bar size, shape, and type, plus the weight capacity, are discussed to produce serrated steel bar grating that is sturdy, economical, enduring, and practical for the customer.

Surface finishing, surface kinds, non-standard specifications, banding, fabrication, notching, cut-outs, toe boards, Stair Treads, and other special customizations are also considered when discussing with the customer.

This plan of action typically entails about 1 or 2 days.

2. Preparing Raw Material:

When the design is complete, our manufacturing team begins sourcing and preparing the highest quality raw materials for the serrated steel bar grating. All primary materials are purchased from reputable suppliers and examined to guarantee they are eco-friendly, durable, and of high quality.

Typically, raw and primary material processing requires 4 to 5 days. Nevertheless, finding personalized and unique materials may take considerably more time.

3. Manufacturing of Steel Grating:

The different types of steel bar gratings, including swage-locked, press-locked, riveted, and welded steel bar grating, are manufactured with slight changes in the procedure.

The slots are first punched on both bearing and cross bars for the press-locked steel bar grating. Then these bars are placed onto each other perpendicularly to form a grid and are fixed together using extra force hydraulic pressure.

For the swage-locked steel bar grating, there are diamond-shaped apertures made on bearing bars (plates) with a machine’s help, irrespective of whether they are the I-bar, rectangular bar, or T-bar. Following that, the crossbar, either round or square-twisted, is put into the pre-punched holes of the bearing bars (plates) to produce a grid-like structure. Machines on the manufacturing line are also used in this procedure. Finally, hydraulic pressure is applied to them to fix their shape in place.

The bearing bars constructed of steel strips are neither notched nor pierced for welded serrated steel bar grating. The drawn and twisted steel cross bars are instead forced into the bearing bars, and resistance is welded at every junction to achieve high stiffness.

For riveted serrated steel bar grating, bearing bars and crimp bars are placed together to achieve the desired design and then joined together using rivets by a hydraulic machine.

The entire manufacturing for all of these serrated steel bar grating types may go on for approximately as low as five days or as high as eight days.

4. Surface Finishing:

Always considering the customer’s opinion, the surface of the manufactured serrated steel bar is coated with either paint or powder. Other ways its surface finishing may be done is through hot dip galvanizing or mill finishing.

About three days are enough for this process to take place.

5. Product Finalizing:

After the serrated steel bar grating is ready, the product is carefully examined for any irregularities or defects. It is checked to see if it fulfills our quality requirements.

Then the grating is packaged and dispatched to our client after approval.

The finishing and packaging process normally takes three days, while shipping might take anywhere from five to forty-five days, depending on the specified address and delivery method.

The Advantage of Serrated Steel Bar Grating

Simple to install and uninstall

Long lifetime, High resistance,

Non-slip and non-corrosive effect

High strength and High weight-bearing capacity

The Certificate of Serrated Steel Bar Grating

The Application of Serrated Steel Bar Grating

Industrial: Serrated steel bar grating can be used generally for non-skid and rust-proof applications in industrial applications, mainly for floors, ladders, catwalks, stair treads, platforms, and bridge decking.

Civil, Commercial, and Residential: Serrated steel bar grating could be utilized for decorative and utilitarian purposes, including pedestrian walkways, stair treads, floors, platforms, straight ladders, spiral ladders, entrance ramps, and catwalks.

FAQs for Serrated Steel Bar Grating

A:From design to material to coating and finish, we can make customized serrated steel grating for our clients. We consider all the client’s points, such as application, environment, size, etc., and then manufacture the steel grating accordingly.

A:The welded and press-locked serrated steel gratings have almost the same anti-slip and anti-corrosive features, which also include being easy to install and having a high strength. The press-locked serrated steel grating, however, has a slight edge over the welded steel bar grating as it is also lightweight and has a high bearing capacity.

A:There are various standards that steel grating manufacturers must meet to produce high-quality products. These standards ensure that the finished product is safe to use and will function as intended. Some of the most common standards that steel grating manufacturers must meet include those set by the American Society for Testing and Materials (ASTM), the National Association of Architectural Metal Manufacturers (NAAMM), and the International Organization for Standardization (ISO). Meeting these standards is necessary to produce high-quality and safe serrated steel bar gratings and other products.

A:ChinaGrating’s quality control for their serrated steel bar gratings involves various measures. Our primary process involves inspecting the product at each manufacturing stage and testing it to ensure that it meets or exceeds a set standard. We also use quality control software to monitor our manufacturing process. Besides, we use employee training to ensure that they are continuously operating at peak efficiency, which reduces the number of times they have to test products. On top of that, we have a dedicated QC team with a well-equipped QC lab that look after all the quality processes from raw material to manufacturing to packaging and shipping.

A:Serrated Steel bar gratings can be made from Aluminum, Carbon Steel, and Stainless Steel. If you need these gratings in other metal or material, contact us at ChinaGratings.com for further details.

Contact Us

Get a Quote

- Yanxin Road,Wuxi,Jiangsu,China

- sales@chinagratings.com

- +86-15052255397