304 & 316 Stainless Steel Grating: Corrosion-Resistant Solutions

General Introduction To Stainless Steel Grating: All You Need To Know

- Superior quality stainless steel gratings

- Most reasonable Price

- Excellent customer service

- Worldwide shipping

A Comprehensive Guide to 304 & 316 Stainless Steel Grating

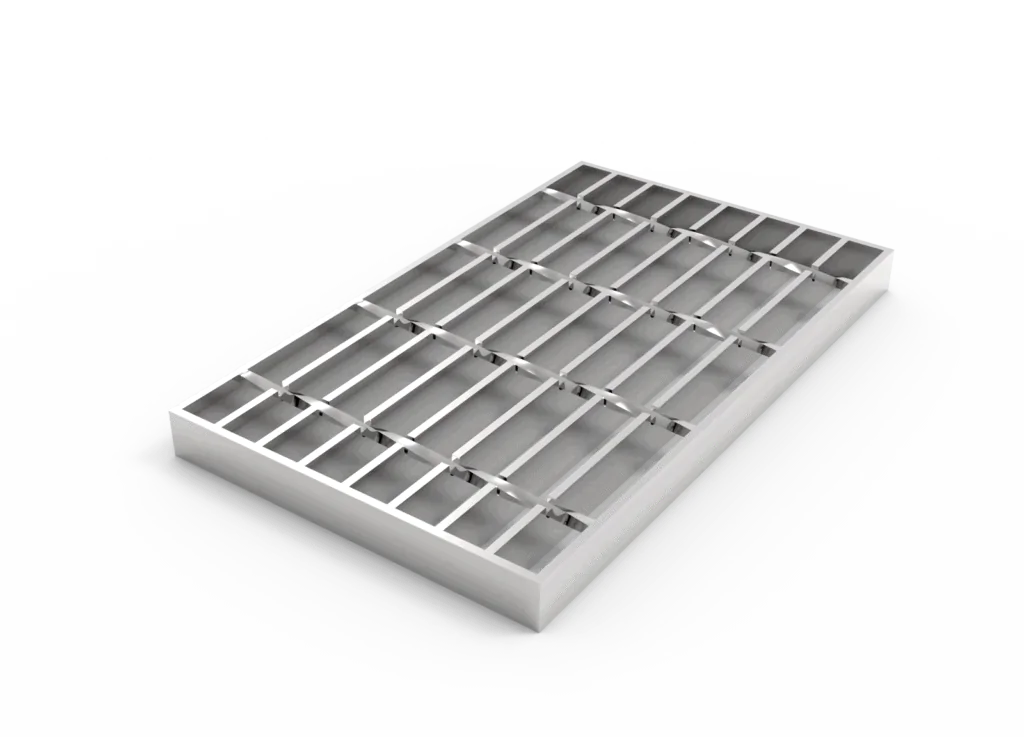

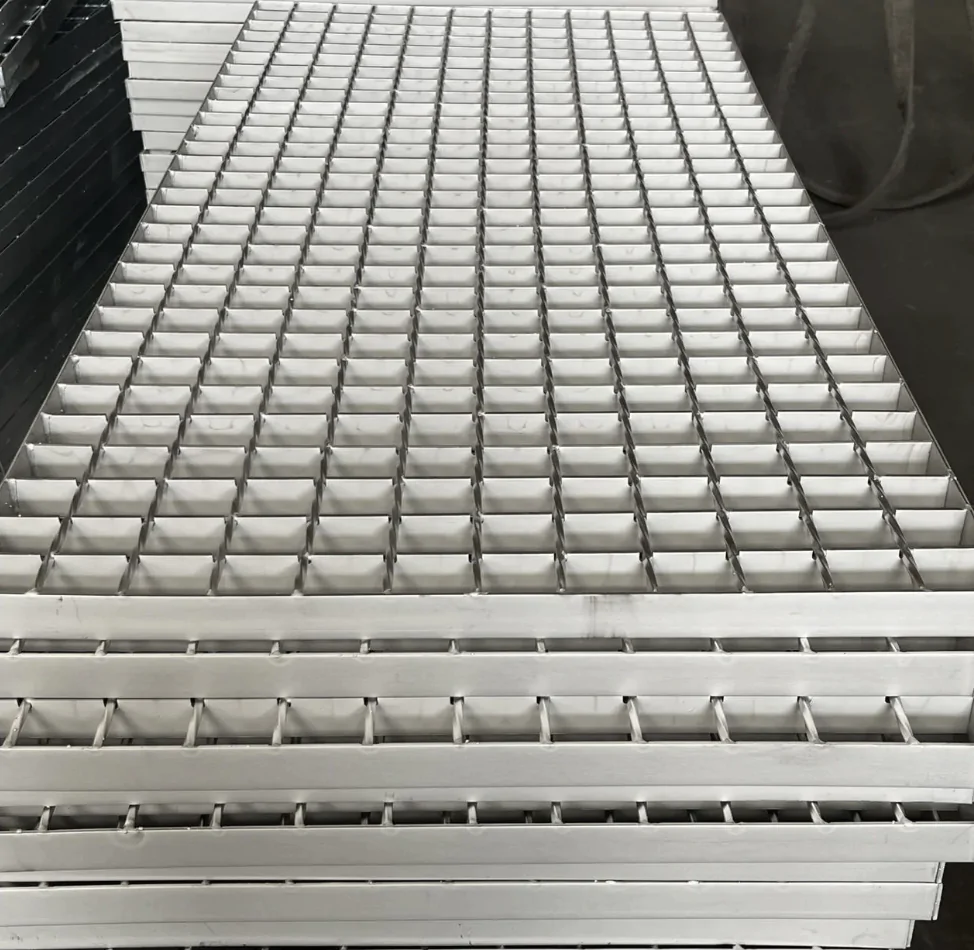

Stainless steel grating is a versatile and durable solution for various industrial and commercial applications, providing exceptional corrosion resistance and hygiene properties. Made from high-quality stainless steel, this grating features an open grid design for strength, stability, and efficient drainage. It is commonly used in food processing plants, chemical facilities, and marine environments.

Available in 304 and 316 stainless steel grades, this grating caters to specific project requirements. Both grades offer excellent resistance to chemicals and atmospheric conditions, with 316 stainless steel providing enhanced corrosion resistance due to added molybdenum. Manufactured in styles such as welded, swage-locked, or press-locked, and customizable in size and load capacity, stainless steel grating meets the unique demands of any project.

Stainless Steel Grating Specification

Our hot selling Stainless Steel Grating

SUNJ Grating is the best place to go for all your stainless steel grating needs. We have over 15 years of experience and our team will be happy help you with any welding, shearing or cutting project that comes up!

Welded Stainless Steel Gratings

Press-Locked Stainless Steel Gratings

Why choose Staineless Steel Gratings from us ?

We started our business with one simple goal in mind: to provide high-quality stainless steel products at the most competitive prices with the best service.

SUNJ GRATING LIMITED is one of the first companies in China manufacturing stainless steel gratings. We have many years of experience in the industry and our products are now used all over the world, in a wide variety of applications.

- A complete solution from design to delivery

- The most competitive prices

- The best quality products

- A team of experts who can provide you with advice and support

Types of Stainless Steel Grating

Both welded and press-locked gratings are available in a variety of sizes and configurations.

1.The most common size of the welded grating is 4′ x 8′. This size is also available in press-locked gratings.

2.The most common size of the press-locked grating is 4′ x 8′. This size is also available in welded gratings.

Welded Stainless Steel Grating

Welded stainless steel gratings are made of bearing bars and cross bars. The bearing bar is the main load-bearing component of the grating. It is available in a variety of thicknesses and depths. The crossbar is the secondary load-bearing component of the grating, and it is available in a variety of thicknesses. The two types of bars are joined together using welding, which results in a strong and rigid joint.

Press-Locked Stainless Steel Grating

Press-locked stainless gratings are made of bearing bars and cross bars. The bearing bar is the main load-bearing component of the grating. It is available in a variety of thicknesses and depths. The crossbar is the secondary load-bearing component of the grating, and it is available in a variety of thicknesses. To join the two types of bars together, they are pressed into each other using a high-pressure process. This results in a strong and rigid joint.

Stainless Steel Grating Specification

| Specification | Description |

|---|---|

| Material | 304, 304L, 316, 316L stainless steel |

| Manufacturing Process | Welded, swage-locked, or press-locked |

| Surface Type | Standard plain surface, serrated surface |

| Cross Bar Spacing | 2" or 4", center to center |

| Bearing Bar Spacing | 15/16" or 1-3/16", center to center |

| Bearing Bar Height | 20mm to 60mm |

| Bearing Bar Thickness | 2mm to 5mm |

| Cross Bar Size | 4mm to 10mm diameter |

| Slip Resistance | Serrated or plain surface, depending on the application |

| Installation Method | Welding, clips, or bolts and nuts, depending on the application |

| Compliance | Meets industry standards and applicable building codes, including ASTM, ISO, and ANSI/NAAMM |

LOAD TABLE FOR STAINLESS STEEL GRATING - TYPE W-19 OR P-19

General Introduction To Steel Grating: All You Need To Know

- Superior quality steel gratings

- Most reasonable Price

- Excellent customer service

- Worldwide shipping

General Introduction To Steel Grating: All You Need To Know

- Superior quality steel gratings

- Most reasonable Price

- Excellent customer service

- Worldwide shipping

Spacing Table of Stainless Steel Bar Grating

PART NO. | SPACING | OPEN AREA | DESCRIPTION |

|---|---|---|---|

19-WS-4

19-PS-4 |  | 78% | Bearing bars are positioned at a distance of 1-3/16 inches from each other, while crossbars are set 4 inches apart. This robust industrial flooring design is widely used for platforms, catwalks, mezzanines, and staircases.

|

19-WS-2

19-PS-2 |  | 73% | Bearing bars are positioned 1-3/16 inches apart, with crossbars set at 2 inches apart. This configuration is ideal for shorter spans and scenarios where small-wheeled carts frequently traverse the grating surface. |

15-WS-4

15-PS-4 |  | 75% | Bearing bars are placed 15/16 inches apart, while crossbars are spaced 4 inches apart. This closer spacing of bearing bars enhances load capacity by over 26% in comparison to similar gratings that have bearing bars positioned at 1-3/16 inches apart. |

15-WS-2

15-PS-2 |  | 69% | Bearing bars spaced at 15/16″ on center and cross bars

at 2″ on center. The closer spaced bearing bars and cross bars provide

additional flooring surface to support pedestrian and wheeled traffic. |

11-WS-4

11-PS-4 |  | 68% | Bearing bars are set 11/16 inches apart, and crossbars can be spaced at either 4 inches or 2 inches apart. Types 11-4 and 11-2, featuring 3/16-inch thick bearing bars, conform to the spacing guidelines outlined by the Americans with Disabilities Act. For ADA-compliant installations, ensure that the bearing bars span in the specified direction. |

11-WS-2

11-PS-2 |  | 63% | Bearing bars are positioned 11/16 inches apart, while crossbars can be arranged either 4 inches or 2 inches apart. Types 11-4 and 11-2, which have 3/16-inch thick bearing bars, adhere to the spacing regulations set forth by the Americans with Disabilities Act. When installing for ADA compliance, ensure the bearing bars are oriented according to the specified direction. |

Stainless Steel Grating Fastening Methods

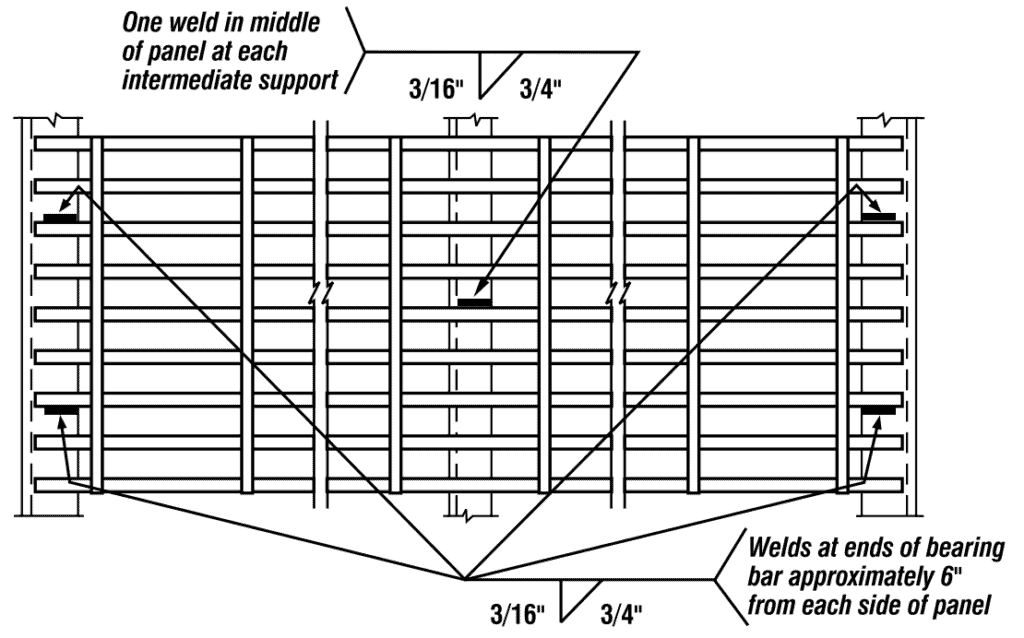

1.Welded Anchorage

Welding is ideal for permanent installations, while mechanical fasteners are a good option for when the grating needs to be removable or welding is not possible. For pedestrian applications, the minimum weld pattern to the right also serves as a guide for minimum fastener spacing. However, for vehicular applications, additional welding, size, and spacing may be required, as determined by the specifying authority.

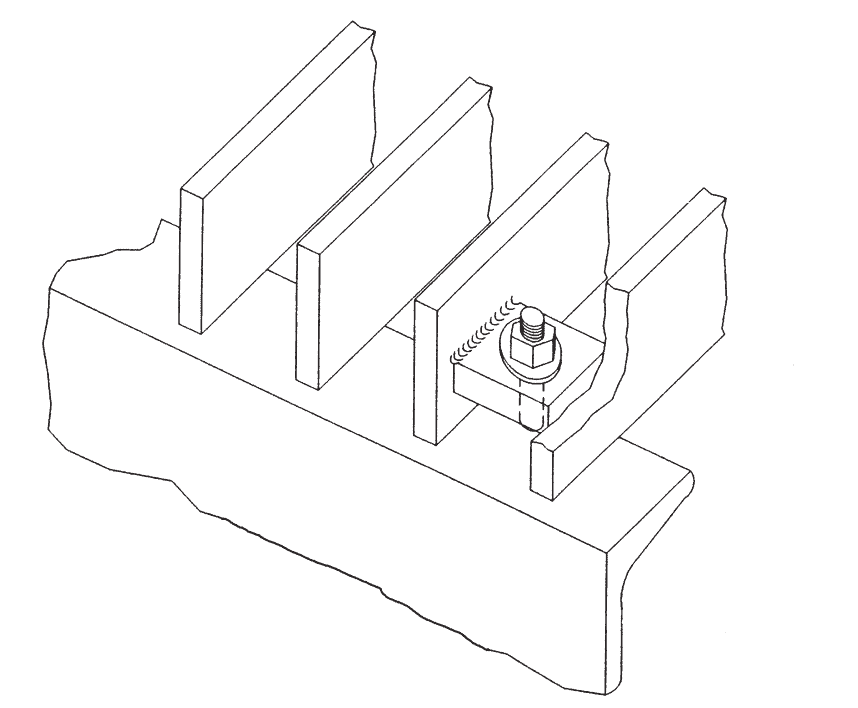

2.Saddle Clips

Our saddle clips are made from steel, stainless steel, or aluminum and are suitable for use in installations where grating may need to be removed. In certain instances, it may be necessary to cut cross bars to accommodate fastener clearance during installation. Typically, saddle clips will be positioned in the same location as the welds unless specified otherwise. The fasteners have a diameter of 1/4 inch (6.4 mm).

3.Weld Lugs

Weld lugs are utilized for installations where the grating may require removal. These lugs will be positioned in the same location as the welds unless otherwise indicated. The fasteners used for weld lugs have a diameter of 1/4 inch (6.4 mm).

The Process Flow for Stainless Steel Grating

Ensure that the gratings will be of the highest quality. A few crucial steps in the manufacturing process need to follow. If these steps follow suit, the gratings will be defect-free and have a long lifespan. Below is an outline of the process flow for manufacturing gratings:

Step 1: Material And Construction:

The first step is to select the appropriate material for the gratings. GI-RO technique offers different constructions of grating, each with its advantages. After deciding which structure to use, the materials are select. The most common materials used are stainless steel and aluminum.

Step 2:Tensioning:

The material is then tensioned to create a tight, even surface. It helps if the surface is not entirely flat but has a slight curvature. Avoiding any distortion in the wavefront and ensuring that the grating is flat is crucial. Stainless steel is tensioned using either a jig or a template.

Step 3: Stainless Steel Gratings In All Sizes:

At GI-RO technique produce stainless steel gratings in all sizes. To using the highest quality materials, cut the gratings to size with a water jet cutter. This results in perfect 90-degree corners and clean, burr-free cut edges.

Step 4:Surface Of The Gratings:

Acid cleaned, brushed, or blasted – the surface of the gratings can be adapted to the customer’s needs. Stainless steel gratings are usually acid-cleaned, which gives them a bright and shiny surface. The gratings can be blasted or brushed if a different surface finish is required.

Step 5: Crossbar Welds:

The gratings are then welded to the crossbars. By using a TIG welder, it is possible to create very small and precise welds. The welder has a special Argon gas protection, which prevents the formation of oxides on the weld.

Step 6:Fixing Of The Gratings:

After the gratings are welded to the crossbars, they need to be fixed. To fix the gratings, they are welded or screwed to the supporting structure. In this way, the gratings are securely fastened and cannot be removed without damaging them.

Step 7:End Products:

The gratings are now ready to be used! They can deliver in either sheets or ready-to-install panels. If the customer needs a specific size or shape, the GI-RO technique can also cut the gratings to order.

The advantage of our Stainless Steel Grating

Stainless steel grating is a new type of product that has many advantages over traditional products.

It is made of high-quality materials that are resistant to corrosion, and it is available in a variety of sizes and configurations.

It is easy to install, and it is a strong and rigid product that can withstand heavy loads.

It is easy to clean, and it does not require much maintenance.

Quality Certification of Stainless Steel Gratings

Frequently Asked Questions

A stainless steel grating is a metal grate that is made out of stainless steel. It is used in various applications, such as in commercial kitchens and food processing plants, where it helps to keep the floor clean and free of debris.

When choosing a stainless steel grating, you need to consider the size, shape, and thickness of the metal grate. You also need to decide if you want a plain or coated grate. Plain gratings are less expensive but they may not last as long as coated gratings. Coated gratings, on the other hand, are more expensive but they are more durable and easier to clean.

The installation of a stainless steel grating is relatively simple. First, you need to mark the location where you want to install the grate. Then, you need to drill holes into the floor so that you can bolt the grating down. Once the grate is bolted down, you need to seal the edges with silicone caulk to prevent water and debris from getting under the grate.

Stainless steel gratings are easy to clean. You can simply hose them down with water or use a pressure washer. If you need to remove tougher dirt and grime, you can use a mild detergent and scrub the grate with a brush. For best results, you should clean your stainless steel grating on a regular basis.

Stainless steel gratings are very durable and they can last for many years. However, they may eventually start to show signs of wear and tear. If you notice any damage, you should have the grating repaired or replaced as soon as possible.

Contact Us

Get a Quotes

SUNJ Grating is the best place to go if you need metal gratings! We have over 15 years of experience and our team will be happy to help with any steel gratings needs.

- Yanxin Road,Wuxi,Jiangsu,China

- sales@chinagratings.com

- +86-15052255397