General Introduction To Press-locked Steel Grating: All You Need To Know

- Superior quality press-locked steel gratings

- Most reasonable Price

- Excellent customer service

- Worldwide shipping

Press-locked Steel Grating

General Introduction To Press-locked Steel Grating: All You Need To Know

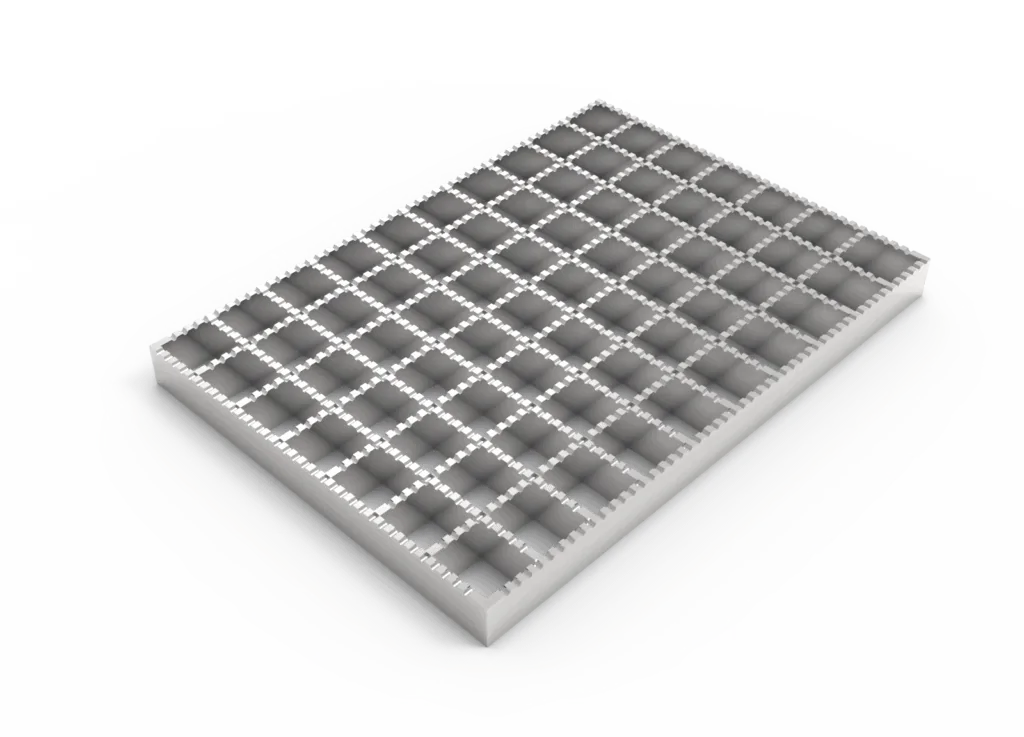

Press-locked steel grating is made by locking the cross bars into the notches of the bearing bars by a pressing process. This type of grating is used where a high level of slip resistance is not required, such as in drainage ditch covers.

Our products are manufactured from steel, stainless steel, and aluminum. We offer a wide variety of sizes and thicknesses. We also offer a complete line of aluminum, stainless steel, bronze, and galvanized grating products.

Press-locked steel grating specification

Our hot selling Press-locked Steel Grating

SUNJ Grating is the best place to go for all your metal grating needs. We have over 15 years of experience and our team will be happy help you with any welding, shearing or cutting project that comes up!

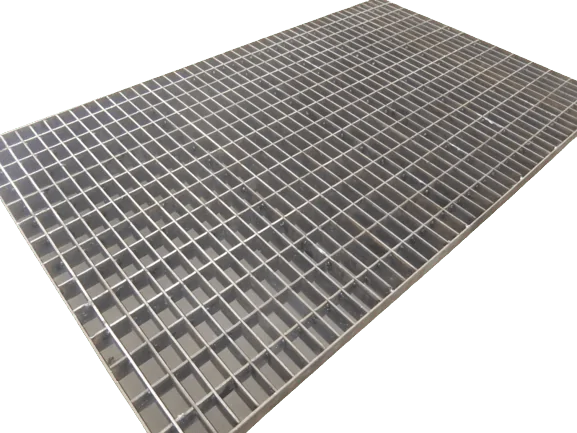

Flat Press-Locked Grating

Serrated Press-Locked Grating

Why choose Press-locked Steel Grating from us ?

SUNJ GRATING LIMITED is a leading Press-locked Steel Grating manufacturer in China. Our products are extensively used as platform grating in the construction of oil platforms, catwalks in the power industry, walkways, and stair treads in industrial plants and parking garages. Our Press-locked Steel Grating is also used in architectural applications such as roof grates and drains.

- We offer a wide variety of sizes and thicknesses

- We also offer a complete line of aluminum, stainless steel, bronze, and galvanized grating products

- Our Press-locked Steel Grating is also used in architectural applications such as roof grates and drains

- We offer a wide variety of sizes and thicknesses

Types of Press-locked Steel Grating

Press-locked Steel Grating is available in a variety of styles and sizes. In terms of types, there are two main types of Press-locked Steel Grating: flat press-locked steel gratings and serrated press-locked steel gratings.

Flat Press-Locked Grating

The flat press-locked grating has a smooth surface and is available in a variety of sizes. The main advantage of this type of grating is that it is easy to clean and maintain. It is also slip-resistant and can be used in areas where there is a risk of slipping, such as in industrial plants or parking garages. All of our flat press-locked grating products are custom-made to your specifications.

Serrated Press-Locked Grating

Serrated press-locked grating has a raised surface and is available in a variety of sizes and thicknesses. This type of grating is ideal for areas where there is a need for good traction, such as in industrial plants or parking garages. Such grating is also slip-resistant. We offer a wide variety of sizes and thicknesses for our bar press-locked grating products.

Press Locked Steel Grating Specifications

| Specification | Description |

|---|---|

| Material | Carbon steel, stainless steel, or aluminum |

| Surface Treatment | Hot-dip galvanized (for carbon steel), mill finish, or powder coated |

| Surface Type | Standard plain surface, serrated surface |

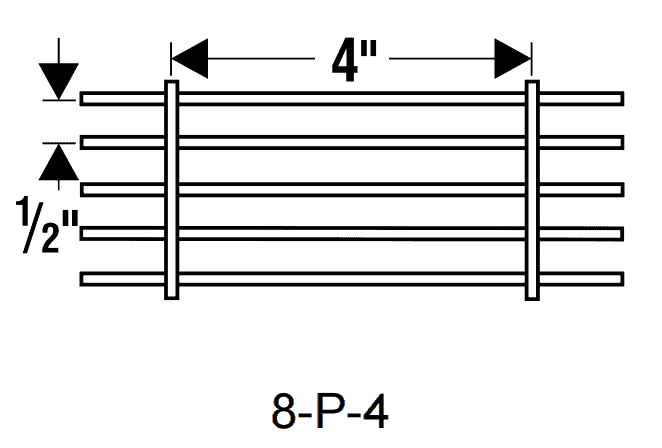

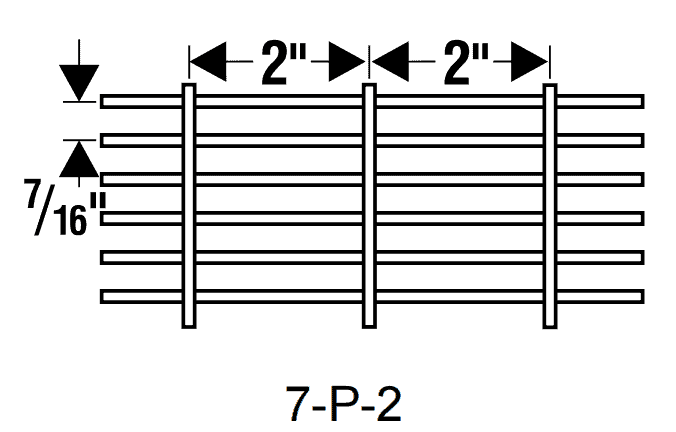

| Cross Bar Spacing | 2" or 4" |

| Bearing Bar Spacing | Standard is 15/16" or 1-3/16" |

| Installation Method | Welding, clips, or bolts and nuts, depending on the application |

| Compliance | Meets industry standards and applicable building codes, including ASTM, ISO, and ANSI/NAAMM |

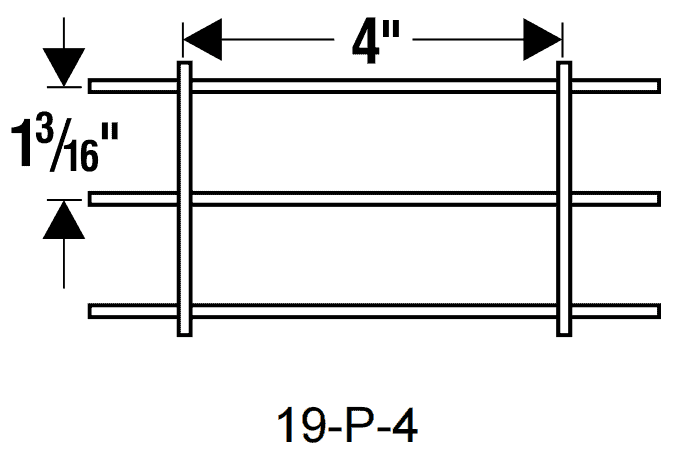

Press Locked Steel Grating Size

| Item | Bearing Bar Size(inches) | Bearing Bar Spacing | Cross Bar Spacing |

|---|---|---|---|

| 19-P-2; 19-P-4 | 3/4"x1/8" | 1-3/16" | 2", 4" |

| 19-P-2; 19-P-4 | 1"x1/8" | 1-3/16" | 2", 4" |

| 19-P-2; 19-P-4 | 1-1/4"x1/8" | 1-3/16" | 2", 4" |

| 19-P-2; 19-P-4 | 1-1/2"x1/8" | 1-3/16" | 2", 4" |

| 19-P-2; 19-P-4 | 3/4"x3/16" | 1-3/16" | 2", 4" |

| 19-P-2; 19-P-4 | 1"x3/16" | 1-3/16" | 2", 4" |

| 19-P-2; 19-P-4 | 1-1/4"x3/16" | 1-3/16" | 2", 4" |

| 19-P-2; 19-P-4 | 1-1/2"x3/16" | 1-3/16" | 2", 4" |

| 19-P-2; 19-P-4 | 1-3/4"x3/16" | 1-3/16" | 2", 4" |

| 19-P-2; 19-P-4 | 2"x3/16" | 1-3/16" | 2", 4" |

| 19-P-2; 19-P-4 | 2-1/4"x3/16" | 1-3/16" | 2", 4" |

| 19-P-2; 19-P-4 | 2-1/2"x3/16" | 1-3/16" | 2", 4" |

| 15-P-2; 15-P-4 | 3/4"x1/8" | 15/16" | 2", 4" |

| 15-P-2; 15-P-4 | 1"x1/8" | 15/16" | 2", 4" |

| 15-P-2; 15-P-4 | 1-1/4"x1/8" | 15/16" | 2", 4" |

| 15-P-2; 15-P-4 | 1-1/2"x1/8" | 15/16" | 2", 4" |

| 15-P-2; 15-P-4 | 3/4"x3/16" | 15/16" | 2", 4" |

| 15-P-2; 15-P-4 | 1"x3/16" | 15/16" | 2", 4" |

| 15-P-2; 15-P-4 | 1-1/4"x3/16" | 15/16" | 2", 4" |

| 15-P-2; 15-P-4 | 1-1/2"x3/16" | 15/16" | 2", 4" |

| 15-P-2; 15-P-4 | 1-3/4"x3/16" | 15/16" | 2", 4" |

| 15-P-2; 15-P-4 | 2"x3/16" | 15/16" | 2", 4" |

| 15-P-2; 15-P-4 | 2-1/4"x3/16" | 15/16" | 2", 4" |

| 15-P-2; 15-P-4 | 2-1/2"x3/16" | 15/16" | 2", 4" |

Press-locked steel bar grating size types

General Introduction To Steel Grating: All You Need To Know

- Superior quality steel gratings

- Most reasonable Price

- Excellent customer service

- Worldwide shipping

The type and mark of Press-locked Steel Grating

Note:

1.Bearing bar pitches may be 15 to 20、25、30、33、

35、38、40、50、60、80、90mm, of which 25、30、

35 and 40mm are recommended.

2.Cross bar pitches may be 30-100mm, of which 50mm, 76mm

and 100mm are recommended.

3.Sign of the shape of bearing bars: F-Plainstyle (may be omitted in the symbol of steel grating)

S-serrated style

I-I-section style

IS-I-section serrated style

4.Sign of surface-treatment:

G-Hot Galvanizing(may be omitted in the symbol of steel grating)

P-Painted

U-Untreated

Press-locked Steel Grating Fastening Methods

We,SUNJ Grating, provide a range of grating fixing components to our customers, which are designed to ensure fast and secure installation of platform gratings. Our fasteners are specifically selected to match the intended use of the grating and are available in a variety of types and materials to suit different environments and requirements.

To ensure maximum durability and longevity, all of our grating fasteners are coated with anti-corrosion materials. We also offer stainless steel fasteners, which are particularly suited for use in harsh or corrosive environments.

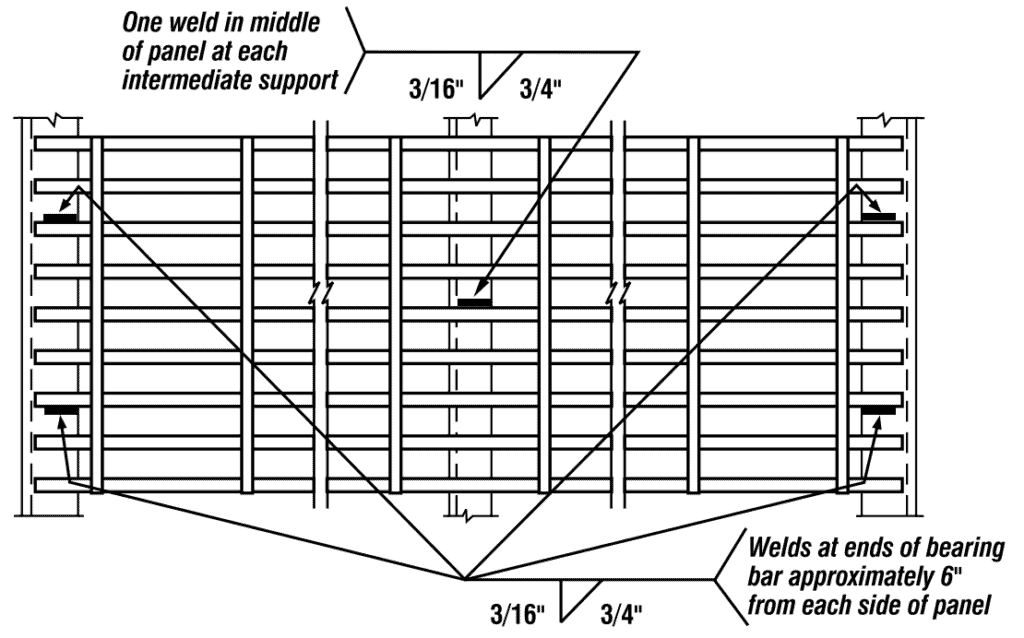

1.Welded Anchorage

Welding is ideal for permanent installations, while mechanical fasteners are a good option for when the grating needs to be removable or welding is not possible. For pedestrian applications, the minimum weld pattern to the right also serves as a guide for minimum fastener spacing. However, for vehicular applications, additional welding, size, and spacing may be required, as determined by the specifying authority.

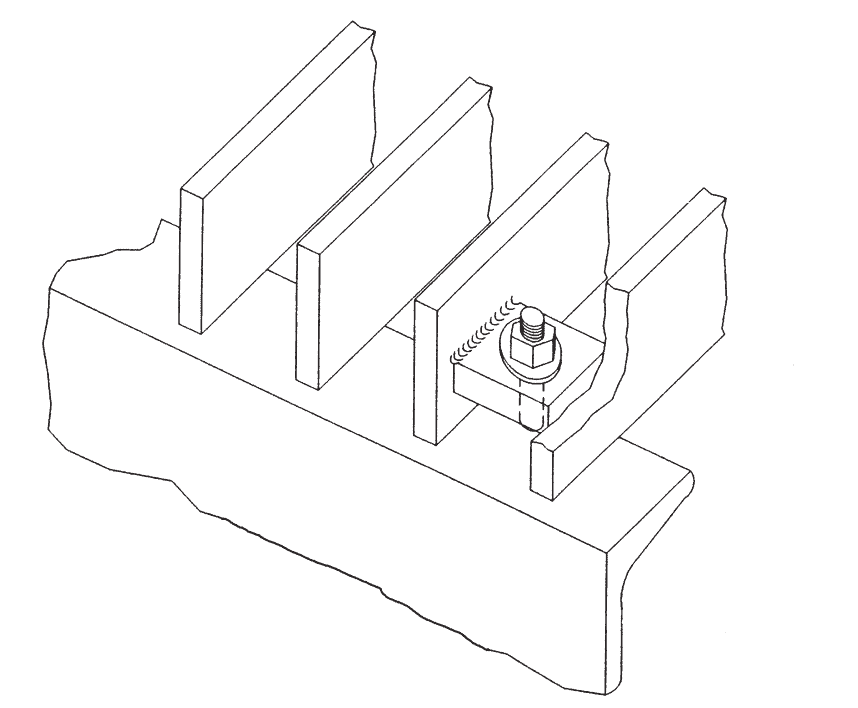

2.Saddle Clips

Our saddle clips are made from steel, stainless steel, or aluminum and are suitable for use in installations where grating may need to be removed. In certain instances, it may be necessary to cut cross bars to accommodate fastener clearance during installation. Typically, saddle clips will be positioned in the same location as the welds unless specified otherwise. The fasteners have a diameter of 1/4 inch (6.4 mm).

3.Weld Lugs

Weld lugs are utilized for installations where the grating may require removal. These lugs will be positioned in the same location as the welds unless otherwise indicated. The fasteners used for weld lugs have a diameter of 1/4 inch (6.4 mm).

The Process Flow for Press-locked Steel Grating

Step 1: Design Consultation(1-2 days)

Before the production process begins, our team of experts will consult with you to determine the best design for your project. We take into account the intended use of the final product, the dimensions and weight of the load, the environment in which it will be used, and any other relevant factors. This ensures that your steel gratings will be up to the task and will last for years to come.

Step 2:Preparing raw materials(1-2 days)

The quality of the raw materials used is crucial to the quality of the final product. We only use the best materials available to create our steel gratings, ensuring that your product will meet or exceed your expectations. Also, all of our materials are sourced from sustainable and environmentally friendly suppliers.

Step 3:Welding of steel gratings(5 days)

Once the design is finalized and the raw materials have been sourced, the manufacturing process can begin. The first step is pressure welding, in which panels are welded together to create the desired shape. This is done using a high-pressure welding machine that creates a strong, stable bond between the panels.

Step 4:Press-locking of steel gratings(3 days)

After the welding process is complete, the steel gratings are moved to the products workshop for finishing. Here, any necessary cuts or holes are made, and the gratings are given a final inspection to ensure that they meet our high standards. Once they have passed inspection, the gratings are ready to be shipped to our clients.

Step 5:Products Finishing(3 days)

After the welding process is complete, the steel gratings are moved to the products workshop for finishing. Here, any necessary cuts or holes are made, and the gratings are given a final inspection to ensure that they meet our high standards. Once they have passed inspection, the gratings are ready to be shipped to our clients.

Step 6:Quality Inspection(1-2 days)

After the welding process is complete, the steel gratings are moved to the products workshop for finishing. Here, any necessary cuts or holes are made, and the gratings are given a final inspection to ensure that they meet our high standards. Once they have passed inspection, the gratings are ready to be shipped to our clients.

Step 7:Packaging(1 days)

To ensure that the products are not damaged during transport, we use high-quality packing materials.the packing of steel gratings requires special care and attention. Be sure to wrap each grate in a layer of plastic film, place them in a box or crate, and fill the gaps between the grates with packing material such as styrofoam peanuts or bubble wrap. Seal the box or crate with tape and label it with the contents and the date. These packing tips will help to ensure that your steel grates are protected from rust and corrosion during storage or transportation.

The advantage of our Press locked Steel Grating

It is easy to clean and maintain

It is slip-resistant

It can be used in a variety of applications, such as in industrial plants or parking garages

It is available in a variety of sizes and thicknesses

Quality Certification of Press locked Steel Grating

FAQs for Press-locked Steel Grating

Press-locked steel grating is a type of metal grating that is pressed and locked together at the joints by a high-pressure process. This results in a stronger, more rigid grating that is less likely to loosen over time.

Press-locked steel grating can be used in a variety of applications, such as walkways, mezzanines, and industrial platforms.

Press-locked steel grating is easy to install and can be done with basic hand tools. Simply align the grating panels at the joints and use clamps or bolts to secure them in place.

Press-locked steel grating is easy to clean and can be done with a broom or pressure washer. For more stubborn dirt and grime, you can use a mild detergent or degreaser. Be sure to rinse the grating afterwards to remove any residue.

Press-locked steel grating is designed for long-term durability and can last for decades with proper maintenance. However, the lifespan will vary depending on the application and environment.

Contact Us

Get a Quotes

SUNJ Grating is the best place to go if you need metal gratings! We have over 15 years of experience and our team will be happy to help with any steel gratings needs.

- Yanxin Road,Wuxi,Jiangsu,China

- sales@chinagratings.com

- +86-15052255397