Steel gratings are an important component for many industrial and commercial applications. From industrial walkways and platforms to outdoor drainage systems, steel gratings provide a durable and reliable solution for a variety of needs. Understanding the specifications of steel gratings is essential to ensure they are the right fit for your project.

The specifications of a welded steel grating vary depending on the application and requirements, but some common features include material, load-bearing capacity, size, finish, and compliance. Gratings come in a range of standard sizes, from small walkway grates to large industrial gratings, and can also be custom-made to fit any space.

We invite you to continue this insightful journey with us, as we unravel the intriguing nuances of steel gratings and their specifications. Fully grasp this concept to enhance your construction projects and gain the expertise required for optimal selection and application.

What is steel grating?

Steel gratings are a type of metal structure designed to provide strong support and durability in a wide range of applications. They are made up of a series of cross-bars that are joined together in an open-mesh pattern. This allows for a wide range of shapes, sizes, and configurations to suit a variety of needs.

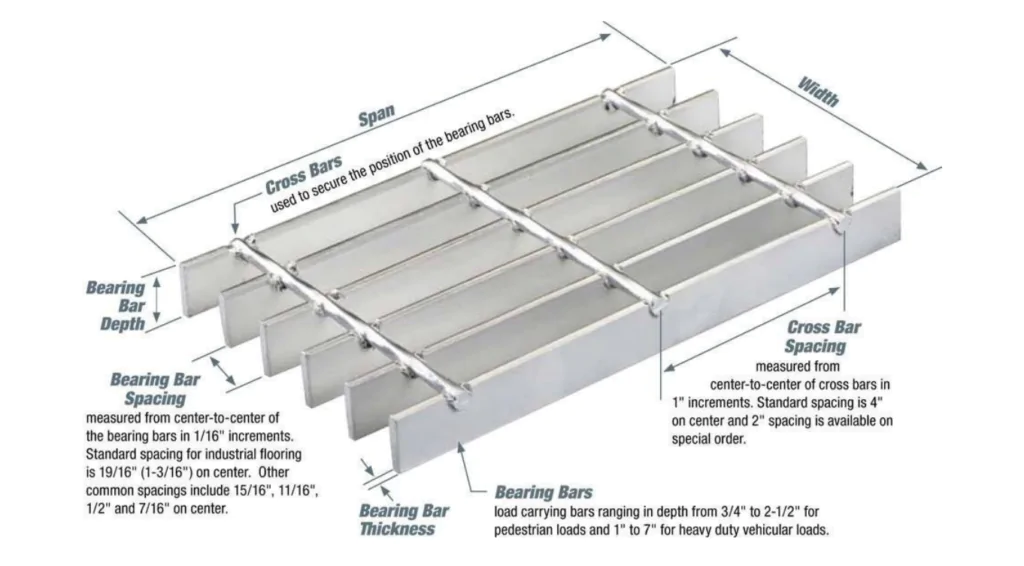

Steel grating is made up of two components: a bearing bar, which is the main structural support, and a cross-bar, which is used to connect the bearing bars. The bearing bars are typically made from hot-rolled steel and can be either plain or serrated, depending on the application. The cross-bars are typically made from either cold-rolled steel or aluminum and can also be serrated or plain.

The specification of welded steel grating is determined by the load-bearing capacity, the spacing between the bearing bars, and the type of cross-bar used. The application of the heavy-duty welded steel grating will determine the best specification for the project.

How to understand the specification of steel gratings

Crossbar

A crossbar of heavy-duty welded steel gratings is a steel bar or rod that is used to create a support structure for a variety of applications. Steel gratings are commonly used in industrial, commercial, and residential settings, as they provide a strong and durable framework for a variety of purposes.

The crossbar of heavy-duty welded steel gratings can be configured to fit a variety of needs, from a lightweight support structure to a more rigid framework. Understanding how to install and utilize the steel gratings properly and the crossbar is important for the successful installation and use of the gratings.

Proper installation of the carbon steel crossbar will ensure a strong and secure structure that will last for many years. Knowledge of the different types of crossbars and their various uses will help determine the best option for any given application.

Bearing bar

The carbon steel bearing bar of steel gratings is an important component of the grating structure. It is the load-bearing member of the grating and is typically made of steel that has been hot-dipped galvanized or has a powder-coated finish.

The carbon steel bearing bar is available in a variety of shapes and sizes, including rectangular, round, and square, as well as in serrated and plain surfaces. The spacing between bearing bars and cross bars can be customized to meet the specific requirements of the application, and the size and shape of the bearing bars can also be altered to meet the application’s load-bearing requirements of the steel bar grating.

The bearing bar is one of the most important elements of the overall construction of steel bar grating, and understanding the bearing bar is essential for proper installation and maintenance.

Span

Steel gratings are spans of metal bars arranged in a crisscross pattern. These grates of steel bar gratings are often used in industrial, commercial, and residential settings such as walkways, fencing, drains, and more. Steel grates are durable and resistant to corrosion, which makes them an ideal choice for many applications.

Understanding the span of steel bar grating requires knowledge of the different types of grates available, the measurements and spacing between bars, the type of metal used, and the weight rating. With this information in hand, it is easier to select the right steel grate for the job.

- Pitch / Spacing

Steel gratings are metal grids made up of a series of parallel, evenly spaced metal bars that are connected by crossbars to form a rectangular or square pattern. The pitch of a steel bar grating is the distance between the centers of two adjacent metal bars.

Understanding the pitch of steel bar grating is important as it determines the spacing between the metal bars and thus affects both the safety and aesthetic factors of the application. The pitch of a steel grating is typically measured in millimeters and can range from 15mm to 50mm, depending on the application.

The spacing of steel gratings refers to the distance between the center of one bearing bar to the center of the adjacent bearing bar. This distance is usually determined by the application the grating will be used for, as well as the load rating the grating needs to have.

For example, a grating that will need to have a high load rating may have a spacing of closer than 3 inches, while a grating for a pedestrian walkway may have a spacing of up to 4 inches. It is important to understand the spacing of steel gratings as it will affect the overall performance of the grating and the safety of the users.

- Depth

Steel gratings are a common product used in many industries, from commercial to industrial to residential applications. Understanding the depth of steel gratings is important for choosing the correct product for your project. Steel gratings are typically measured in inches and the depth of the grating refers to the thickness of the metal.

Generally, the deeper the grating, the more load it can hold and the more durable it will be. The most common depths are 1/4 inch, 1/2 inch, and 3/4 inch. When choosing a steel grating, it is important to consider the weight of the items being placed on the grating, the type of environment it will be used in, and the desired aesthetics.

Aesthetically pleasing due to its hot dip galvanized surface, notched bearing bar, or a deep crossbar on its bar grating. Knowing the depth of the steel bar grating will help you make the right choice for your project.

Steel gratings are often used in a variety of industrial plants and commercial applications, such as machine guards, flooring, trench covers, stair treads, and catwalks. Understanding the thickness of steel bar grating is essential to ensure the desired level of strength and durability.

Steel grating is typically measured in gauge, which is the thickness of the metal used in the product to make it a safety grating. Generally, the thicker the steel bar grating, the more robust and durable the product will be on its hot dip serrated surface.

Additionally, if you are considering steel products for an application that requires a higher level of strength, such as a machine guard, a thicker steel bar grating will be the best option. Knowing the exact thickness of the metal gratings needed for your application is key to selecting the correct product.

The advantages of steel gratings

Steel gratings offer a wide range of advantages for building and engineering projects, from infrastructure to design. They are strong and resistant to corrosion, so they are often used in the construction of walkways, handrails, ramps, stair treads, and other outdoor structures.

Steel gratings are also lightweight, so they can be transported easily and installed quickly. In addition, steel gratings can be customized to fit any space and can be used to create unique designs. Steel gratings are also low-maintenance and require little upkeep, making them ideal for industrial applications.

They are also fire-resistant, which makes them a great choice for areas prone to fire hazards. Steel gratings can also be treated to reduce the amount of noise they produce, making them suitable for serrated surfaces with high noise levels.

Bare steel gratings are also an environmentally friendly choice. They are made from recycled materials and are recyclable themselves, making them a great choice for projects that require sustainable materials.

Steel gratings can also be used with renewable energy sources, such as solar power, which can help reduce the carbon footprint of a project. Finally, steel gratings are incredibly durable and can last for decades with proper maintenance.

Conclusion

Steel gratings are a highly versatile and reliable product for a variety of applications. They are cost-effective, lightweight, and durable, making them a great choice for many industrial, commercial, and residential applications.

Steel gratings are available in a variety of materials, sizes, and designs, making them suitable for almost any application. With their superior strength and corrosion resistance, they are an ideal choice for a variety of applications.