Steel Grating Supplier

General Introduction To Steel Grating: All You Need To Know

- Superior quality steel gratings

- Most reasonable Price

- Excellent customer service

- Worldwide shipping

General Introduction to Steel Grating

Steel grating, also known as metal grating or bar grating, is made by combining flat steel and cross bars in a specific pattern and welding or pressure locking them together.

It can be made in two ways, and the cross bars are usually made of twisted square steel, round steel, or flat steel. Steel gratings are often made of carbon steel and have a galvanized exterior to prevent rust, or they can be made of stainless steel.

They can be used in many places, like gutter covers, steel deck panels, factory floors, and more. Steel gratings are strong, durable, and slip-resistant, making them great for use in industrial and architectural settings.

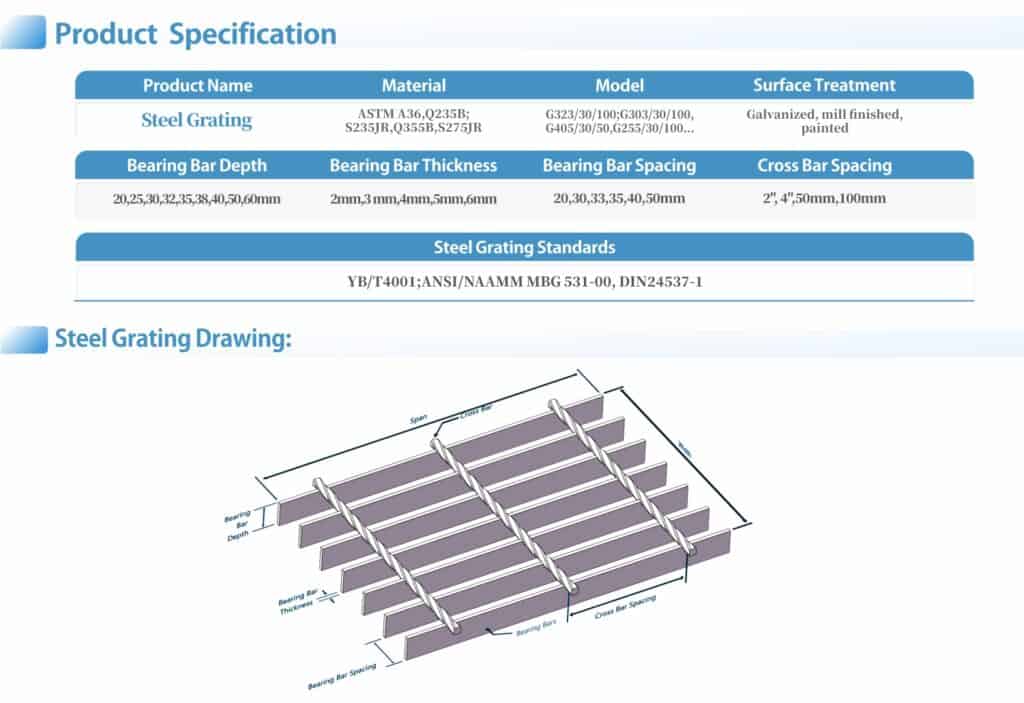

Steel Grating Specification

Our Hot Selling Steel Grating

With 15+ years of production experience, SUNJ Grating is your trusted source for high-quality steel grating. Our strict quality control and factory-direct sales ensure reliable, safe, and durable products.

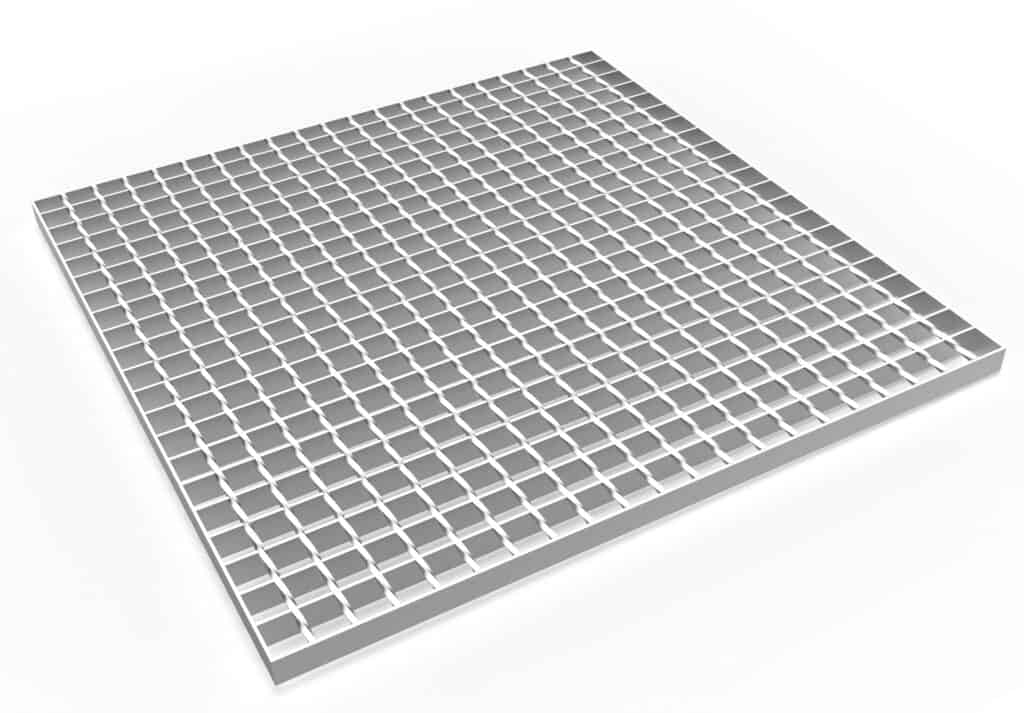

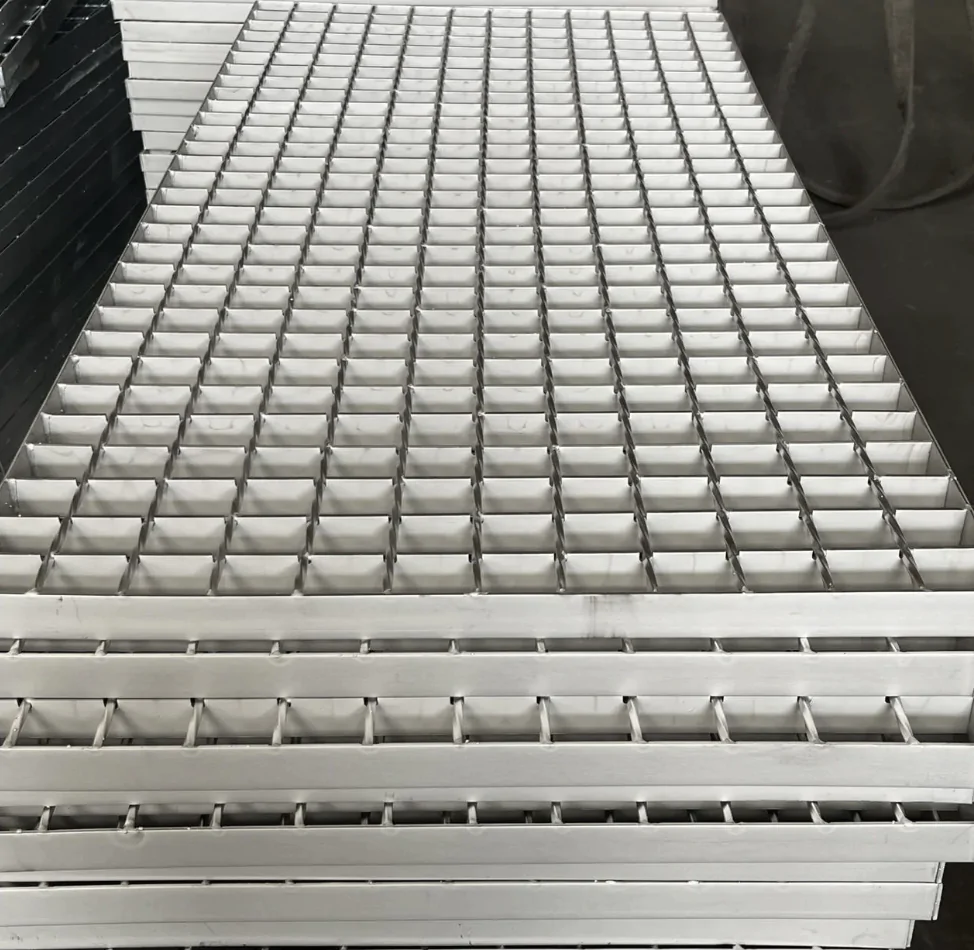

Standard Welded Steel Grating

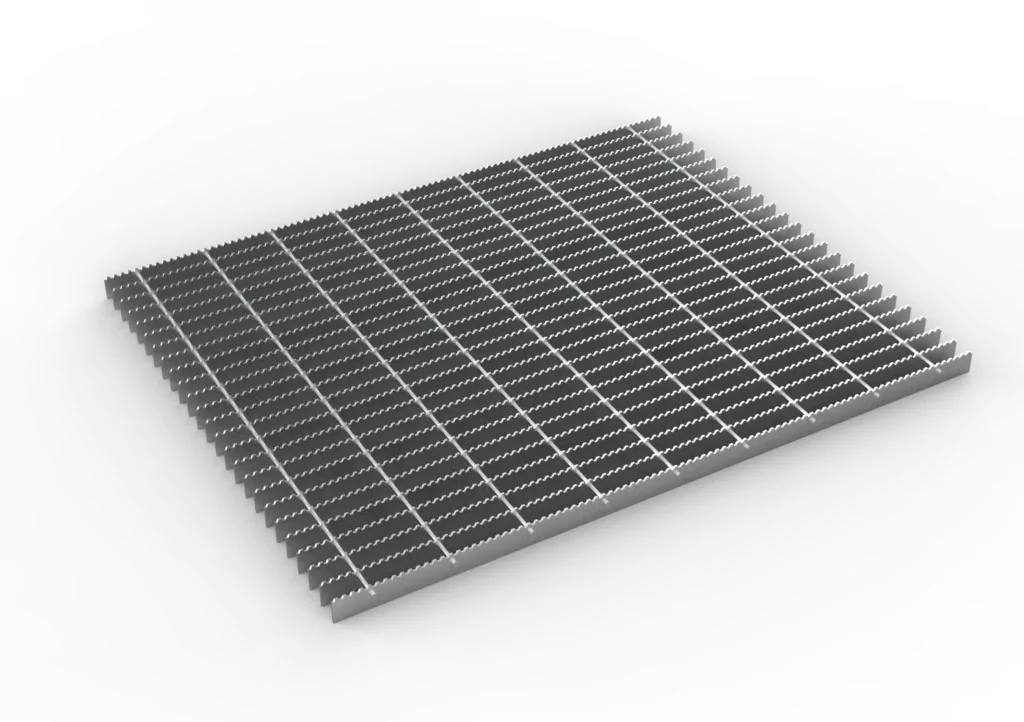

Swage Locked Steel Grating

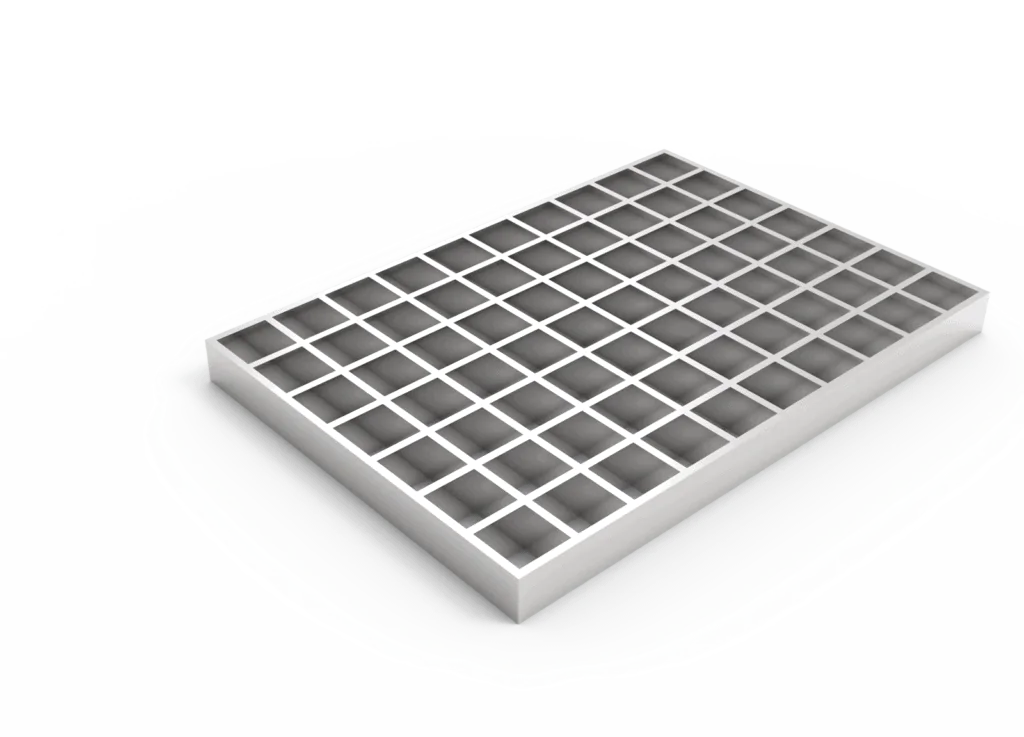

Press-locked Steel Grating

Why choose steel grating from us?

Steel grating are an important part of many industrial and commercial settings. If you’re looking for a supplier of high-quality steel gratings, you should consider SUNJ Grating Limited.

We offer a wide range of steel grating, including galvanized steel grating, stainless steel grating, etc. In addition, we can customize our products to meet your specific requirements. Here are just a few reasons why you should choose us:

- We are the company with over 15 years of experience in the manufacturing and customization of steel gratings.

- We have ISO certification and many years of experience, ensuring that our products are of the highest quality.

- We have a strict quality control system to ensure that all our products meet your requirements.

- We offer large discounts for projects and large orders, as well as a free sample test and customization service.

Types of Steel grating

Welded Steel Grating

welded steel grating is a type of industrial flooring created by welding together flat steel bars and crossbars at right angles. This produces a strong and durable grid-like structure that can support heavy loads and resist impact and fatigue.

Welded steel grating is widely used in industries such as construction, mining, and transportation for platforms, walkways, drainage covers, and other applications where strength and durability are essential.

Type "SL" Swage Locked Steel Grating

Swage-Locked Bar Grating is an industrial steel grating created using a swaging process that locks crossbars securely in place, providing high strength-to-weight ratio, minimal deflection, and maximum safety.

Ideal for industrial platforms, walkways, and catwalks in various settings, including factories, plants, and refineries, as well as power and chemical plants.

Press-locked Steel Grating

Press-locked steel grating is made by locking the cross bars into the notches of the bearing bars by a pressing process. This type of grating is used where a high level of slip resistance is not required, such as in drainage ditch covers.

The Features of Steel Grating

| Property | Description |

|---|---|

| Materials | Carbon steel, stainless steel, aluminum steel |

| Surface Treatment | Galvanized, mill finished, painted |

| Surface Type | Standard plain surface, serrated surface |

| Bearing Bar Spacing | 7/16", 1/2", 11/16", 15/16", 19/16" in 1/16" increments |

| Cross Bar Spacing | 2", 4" in 1" increments |

| Bearing Bar Depth | 3/4" to 7" |

| Bearing Bar Thickness | 1/8" to 1/2" |

| Steel Grating Shape | Square, rectangular, round, half round, hollow circle, special shapes |

| Applications | Catwalks, flooring, stairs, operating platforms, etc. |

Spacing Table of Steel Bar Grating

PART NO. | SPACING | OPEN AREA | DESCRIPTION |

|---|---|---|---|

19-W-4

19-P-4 |  | 78% | Bearing bars are positioned at a distance of 1-3/16 inches from each other, while crossbars are set 4 inches apart. This robust industrial flooring design is widely used for platforms, catwalks, mezzanines, and staircases.

|

19-W-2

19-P-2 |  | 73% | Bearing bars are positioned 1-3/16 inches apart, with crossbars set at 2 inches apart. This configuration is ideal for shorter spans and scenarios where small-wheeled carts frequently traverse the grating surface. |

15-W-4

15-P-4 |  | 75% | Bearing bars are placed 15/16 inches apart, while crossbars are spaced 4 inches apart. This closer spacing of bearing bars enhances load capacity by over 26% in comparison to similar gratings that have bearing bars positioned at 1-3/16 inches apart. |

15-W-2

15-P-2 |  | 69% | Bearing bars spaced at 15/16″ on center and cross bars

at 2″ on center. The closer spaced bearing bars and cross bars provide

additional flooring surface to support pedestrian and wheeled traffic. |

11-W-4

11-P-4 |  | 68% | Bearing bars are set 11/16 inches apart, and crossbars can be spaced at either 4 inches or 2 inches apart. Types 11-4 and 11-2, featuring 3/16-inch thick bearing bars, conform to the spacing guidelines outlined by the Americans with Disabilities Act. For ADA-compliant installations, ensure that the bearing bars span in the specified direction. |

11-W-2

11-P-2 |  | 63% | Bearing bars are positioned 11/16 inches apart, while crossbars can be arranged either 4 inches or 2 inches apart. Types 11-4 and 11-2, which have 3/16-inch thick bearing bars, adhere to the spacing regulations set forth by the Americans with Disabilities Act. When installing for ADA compliance, ensure the bearing bars are oriented according to the specified direction. |

The type and mark of Steel Grating

Note:

1.Bearing bar pitches may be 15 to 20、25、30、33、

35、38、40、50、60、80、90mm, of which 25、30、

35 and 40mm are recommended.

2.Cross bar pitches may be 30-100mm, of which 50mm, 76mm

and 100mm are recommended.

3.Sign of the shape of bearing bars: F-Plainstyle (may be omitted in the symbol of steel grating)

S-serrated style

I-I-section style

IS-I-section serrated style

4.Sign of surface-treatment:

G-Hot Galvanizing(may be omitted in the symbol of steel grating)

P-Painted

U-Untreated

Steel Grating Fastening Methods

We,SUNJ Grating, provide a range of grating fixing components to our customers, which are designed to ensure fast and secure installation of platform gratings. Our fasteners are specifically selected to match the intended use of the grating and are available in a variety of types and materials to suit different environments and requirements.

To ensure maximum durability and longevity, all of our grating fasteners are coated with anti-corrosion materials. We also offer stainless steel fasteners, which are particularly suited for use in harsh or corrosive environments.

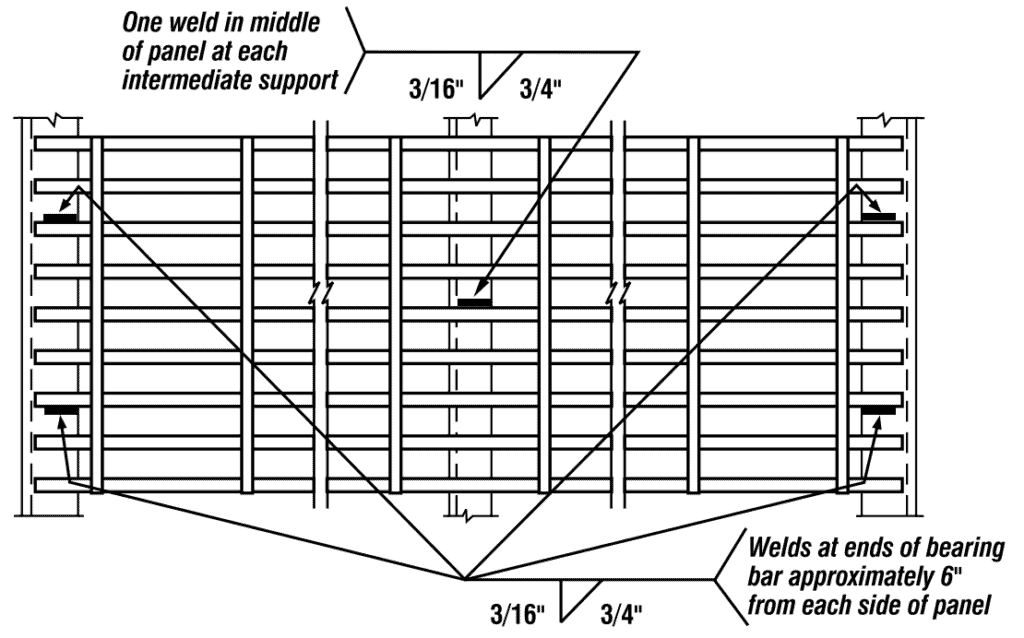

1.Welded Anchorage

Welding is ideal for permanent installations, while mechanical fasteners are a good option for when the grating needs to be removable or welding is not possible. For pedestrian applications, the minimum weld pattern to the right also serves as a guide for minimum fastener spacing. However, for vehicular applications, additional welding, size, and spacing may be required, as determined by the specifying authority.

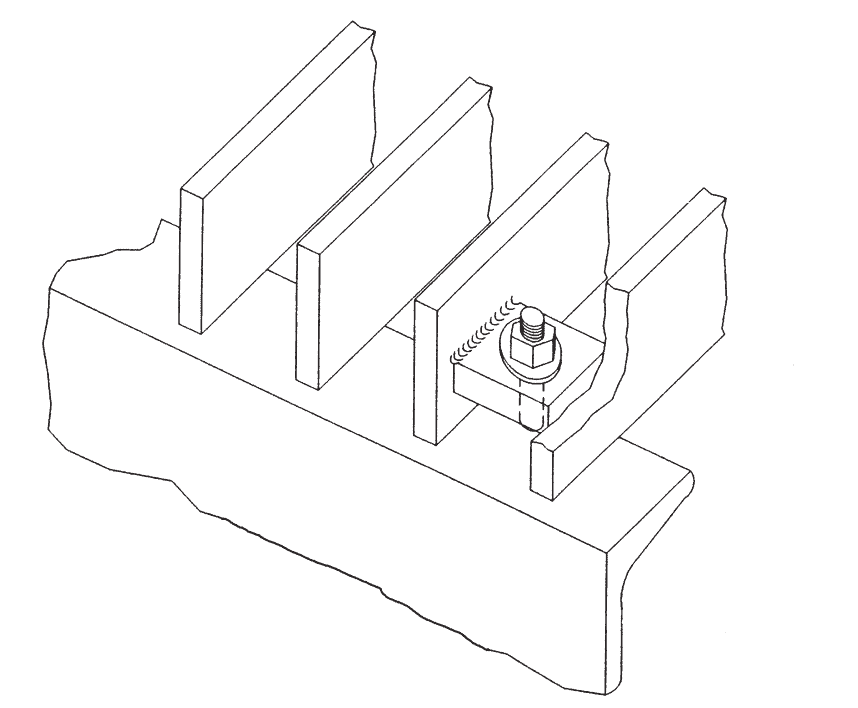

2.Saddle Clips

Our saddle clips are made from steel, stainless steel, or aluminum and are suitable for use in installations where grating may need to be removed. In certain instances, it may be necessary to cut cross bars to accommodate fastener clearance during installation. Typically, saddle clips will be positioned in the same location as the welds unless specified otherwise. The fasteners have a diameter of 1/4 inch (6.4 mm).

3.Weld Lugs

Weld lugs are utilized for installations where the grating may require removal. These lugs will be positioned in the same location as the welds unless otherwise indicated. The fasteners used for weld lugs have a diameter of 1/4 inch (6.4 mm).

The Process Flow & Duration Estimation for Steel Gratings

Step 1: Raw Material Preparation:(1-2 days)

Raw materials for steel gratings can be carbon steel, galvanized steel, or stainless steel. The most common choice is low-carbon mild steel because it is inexpensive and easy to weld. To maintain this process flow, all the materials must be cut to size and cleaned to remove any dirt, grease, or other contaminants. Not to mention, the raw material must go through quality control to be approved.

Step 2:Edge Preparation:

The edge of preparation of steel grating mainly refers to trimming and rounding the advantages of steel gratings. This is to remove any sharp or jagged edges that could cause injury. Doing this, it also gives the grating a more finished look. In addition, the edge preparation also helps to prevent the grating from rusting.

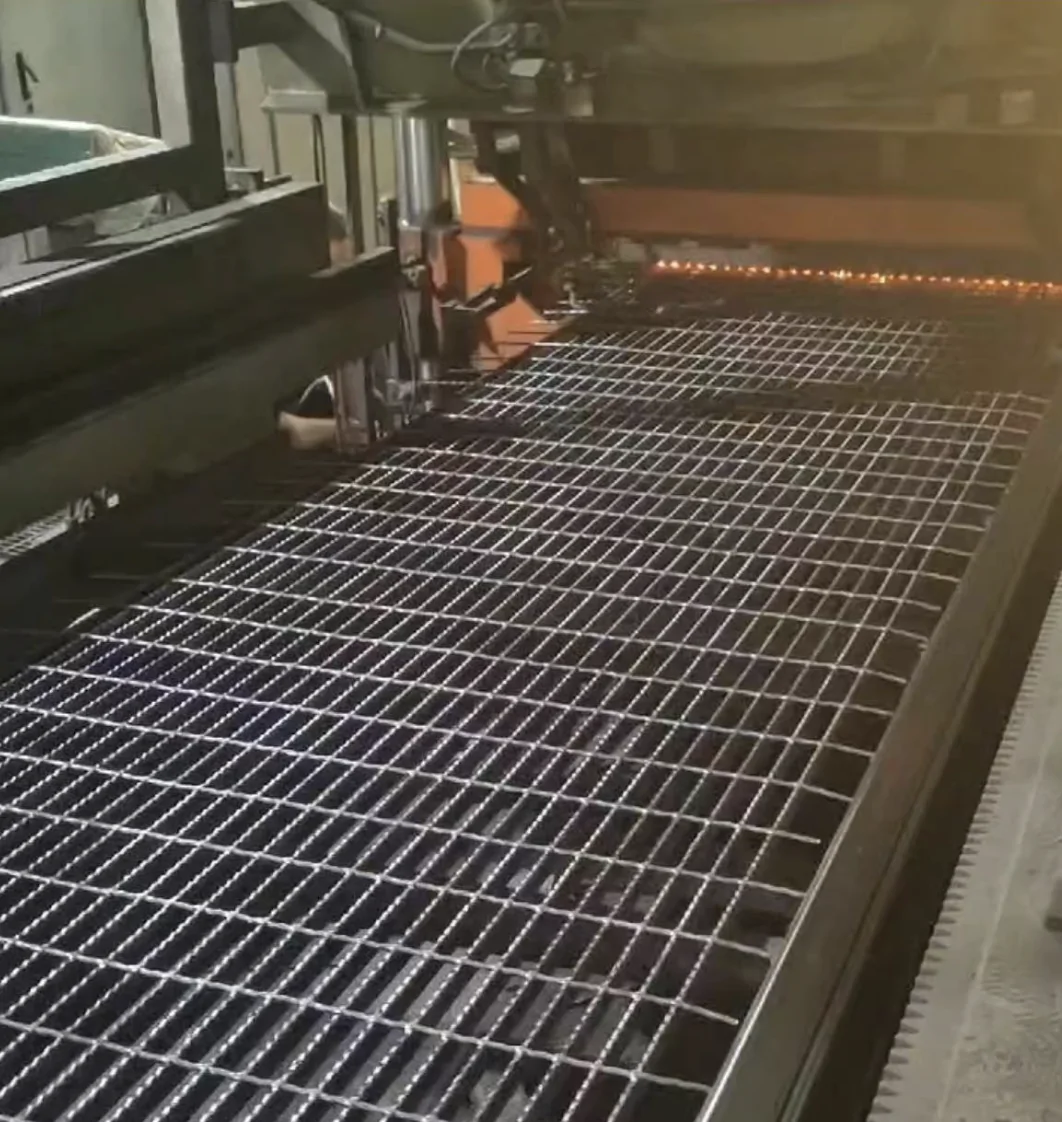

Step 3:Press welding by machine

Steel grating machine is the critical equipment in the process of steel grating. It mainly uses to weld the bearing bar and cross bar together to form a kind of steel grating. There are many steel grating machines; the most common are automatic welding machines, CNC machines, etc.

Step 4:Marking:

Marking is also a part of the process flow of steel grating. Marking mainly indicates steel gratings’ size, type, and other relevant information. With the help of marking, people can easily identify the steel gratings. In addition, it also helps to prevent the steel gratings from being mixed up.

Step 5:Maintenance:

Giving proper maintenance to steel gratings is very important to keep them in good condition. The most familiar way to do this is by regularly cleaning and inspection. Because steel gratings are exposed to many elements, they can quickly get dirty or damaged. By regularly cleaning and inspection, you can prevent this from happening.

Step 6:Inspecting

Inspecting and packaging is the last step in the process flow of steel grating. This is to make sure that the gratings meet the required standards and are free of any defects. Once they inspect, they are then packaged for shipment. Steel grating and other products, like trench drain grating, need to be inspected and packaged before they are shipped out.

Step 7:Packaging(1 days)

To ensure that the products are not damaged during transport, we use high-quality packing materials.the packing of steel gratings requires special care and attention. Be sure to wrap each grate in a layer of plastic film, place them in a box or crate, and fill the gaps between the grates with packing material such as styrofoam peanuts or bubble wrap. Seal the box or crate with tape and label it with the contents and the date. These packing tips will help to ensure that your steel grates are protected from rust and corrosion during storage or transportation.

The Advantage of Our Steel Gratings

High strength, high bearing capacity and high resistance to stress.

Ventilation, lighting and heat dissipation.

Anti-corrosion, anti-rust, durable.

Simple and beautiful appearance.

Quality Certification of Steel Grating

The application of Steel Grating

SUNJ Grating architectural metal products have been widely applied. 70% of our gratings are exported worldwide, such as the United States, Britain, Spain, Netherlands, Australia, New Zealand, Japan, Singapore, Malaysia, Thailand, etc.

Our steel gratings can be found in many large-scale power stations, boiler factories, petroleum engineering projects, municipal construction projects and more.

FAQs for Steel Grating

At SUNJ Grating Solutions, we pride ourselves on providing high-quality products that meet the strictest standards. We offer a variety of steel gratings that are manufactured to meet different specifications, including ANSI/NAAMM (MBG535), ASTM (A36), and more.

There are a few ways that steel quality can be controlled when making gratings. One way is to use a higher-quality steel in the manufacturing process. Additionally, the surface finish of the grating can be controlled by using different types of metal finishes, such as zinc plating or powder coating. Finally, it’s important to have a well-designed and executed manufacturing process in place to ensure that the gratings meet the required specifications.

There are many different types of surface treatments, such as painting, hot-dip galvanizing, electroplating, etc. The most common type of surface treatment is hot-dip galvanizing.

Steel gratings are used for a variety of purposes, including: Walkways and platforms,Safety barriers and fencing,Stairs,Window shutters,Ceiling panels.

There are three main types of steel gratings: welded, press locked, and swaged. Welded steel gratings are the most popular type due to their strength and durability. Press locked steel gratings are also very strong, but are typically used for projects where a smooth surface is required. Swaged steel gratings are less common, but are often used in projects where a very tight fit is required.

Contact Us

Get a Quote

SUNJ Grating is the best place to go if you need metal gratings! We have over 15 years of experience and our team will be happy to help with any steel gratings needs.

- Yanxin Road,Wuxi,Jiangsu,China

- sales@chinagratings.com

- +86-15052255397