Choosing the right materials for a construction project is not just about ensuring stability and durability, it’s also about cost-efficiency and environmental impact. Have you ever wondered how crucial the selection of grating material is to your construction project? It’s an aspect often overlooked, yet it can significantly influence the overall performance and lifespan of your structure.

In the world of industrial flooring, grating plays a crucial role. It is a critical component in industries such as construction, oil and gas, transportation, and manufacturing. It provides structural support and enhances safety in various industries. Two popular options for grating materials are steel and fiberglass.

Let’s delve into the world of steel and fiberglass grating, exploring their composition, characteristics, applications, and advantages!

Description of Steel Grating

Composition and features of steel grating

Steel grating, a versatile structural material, is widely employed for its high strength and load-bearing capacity. Manufactured from a series of flat bars and support rods welded together, steel grating is formed into a grid-like pattern, resulting in an extremely durable and supportive surface.

The main material is low-carbon steel, and stainless steel or aluminum can be used. Steel grating can also be coated for additional strength, durability, and corrosion resistance. Galvanized metal and painted finishes are commonly utilized to ensure a longer lifespan even under challenging environmental conditions.

Steel grating comes in a variety of types to meet different industrial needs. Some common types include welded steel grating, press-locked grating and swage-locked steel grating. Each type offers distinct features and benefits, allowing for customization based on specific project requirements.

| ✅Pros | ❎Cons |

| · High strength and durable · Long service lifespan · Prevents the accumulation of heat · Open-grid design, efficient for drainage | · Needs coating, or will be susceptible to corrosion · Needs regular checks and maintenance |

Applications of steel grating

Steel grating is versatile and can be used in a variety of scenarios. It is commonly utilized in industrial settings for walkways, platforms, and stair treads, owing to its high load capacity and slip resistance.

In addition, it plays a crucial role in the construction sector as it is employed in bridge decking and highway sound barriers due to its excellent strength-to-weight ratio. It’s also used in the architectural field for façade screening, fencing, entrances, and sunshades.

In the utilities sector, steel grating is often used for drainage covers, tree guards, and air vent grids. Its ability to efficiently drain water and tolerate heavy traffic makes it an ideal choice for these applications.

Description of FRP Grating

Composition and features of frp grating

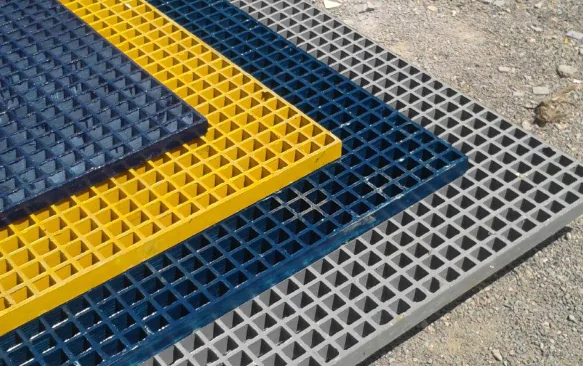

Fiberglass grating is a widely-used flooring option. It is composed of a matrix of resin and reinforced fiberglass strands. Its outstanding corrosion resistance makes it ideal for harsh environments where steel grating may be susceptible to rust and degradation.

Additionally, fiberglass grating exhibits excellent electrical insulation properties and is non-magnetic, making it suitable for certain specialized applications.

Some common types include molded grating and pultruded grating. The different types offer specific characteristics, such as load-bearing capacity, flame resistance, or smaller gaps for particle control. Fiberglass grating has gained significant popularity due to its unique properties and advantages.

| ✅Pros | ❎Cons |

| · High corrosion resistance · Light weight and high strength-to-weight ratio · Easy installment · Increase traction · UV resistance · Low maintenance | · High initial cost · Will suffer from wear and tear over time · Not suitable for situations where conductivity is required |

Applications of FRP grating

Fiberglass grating is prominently used in industrial settings susceptible to corrosive substances, such as chemical plants, wastewater treatment facilities, offshore oil rigs and food processing facilities. The non-slip surface and durability also make it ideal for pedestrian walkways, platforms, and stairs, especially in weather-prone outdoor environments.

In design and architectural projects, fiberglass grating is often used for its aesthetic appeal and the flexibility it offers in terms of color and design. It also finds application in electrical settings due to its non-conductive nature, making it appropriate for telecommunications installations and electrical power plants.

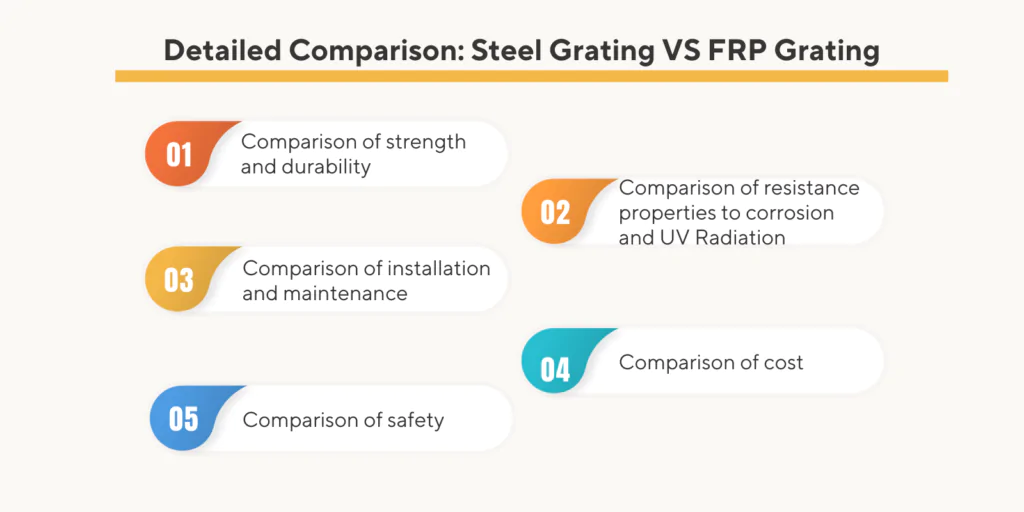

Detailed Comparison: Steel Grating VS FRP Grating

Comparison of strength and durability

Steel grating is renowned for its exceptional strength and load-bearing capabilities. The inherent rigidity and durability of steel make it an ideal choice for heavy-duty industrial applications where high traffic, heavy machinery, or extreme loads are anticipated.

While fiberglass grating may not possess the same level of strength as steel, it can withstand considerable loads without compromising its integrity. Therefore, steel grating excels in heavy-duty industries that demand maximum strength, whereas fiberglass grating is suitable for applications where weight reduction is critical without compromising strength.

Both steel and fiberglass offer a high level of durability but with some key differences. Steel boasts excellent resistance to wear. However, its durability can be compromised over time due to rusting and corrosion. Fiberglass offers exceptional durability due to its corrosion resistance and inert characteristics.

Comparison of resistance properties to corrosion and UV Radiation

One of the key advantages of fiberglass grating over steel is its superior corrosion resistance properties. While steel is prone to rusting and corrosion when exposed to moisture or harsh chemicals, fiberglass remains unaffected by these elements, and it doesn’t require regular maintenance and protective coatings

Besides, fiberglass grating has a higher resistance to UV rays compared to steel. Steel grating, when exposed to UV radiation over time, may experience degradation and corrosion due to the effects of oxidation. On the other hand, fiberglass grating’s inherent resistance helps it maintain its structural integrity and aesthetic appeal even under harsh sunlight conditions.

Comparison of cost

Steel grating is generally more affordable compared to fiberglass grating in terms of upfront costs. However, its long-term costs may increase due to maintenance requirements, periodic painting, and potential replacement in

Fiberglass grating may have a higher initial cost, but it offers long-term cost benefits due to its low maintenance requirements and resistance to corrosion. It eliminates the need for maintenance, reducing overall maintenance and replacement costs over time.

When considering the total cost including installation, maintenance, and potential replacements, fiberglass grating often proves to be more cost-effective in the long run.

Comparison of safety

Steel grating’s anti-slip properties, sturdy construction, and high load-bearing capacity contribute to enhanced safety. Its robust structure allows for steady footing even in demanding conditions, reducing the risk of accidents or slips.

Fiberglass grating is designed with enhanced anti-slip surfaces and often includes special additives for increased traction. Its lightweight nature reduces strain on workers and minimizes the risk of injuries due to lifting or installation accidents. Additionally, its non-conductive properties make it a safer choice in electrical environments.

Both steel and fiberglass grating prioritize safety in different aspects. Steel grating excels in heavy-duty environments, ensuring stable footing and protection against impact. Fiberglass grating, with its non-conductive and anti-slip properties, offers enhanced safety in industries where electrical hazards and lightweight maneuverability are vital.

Factors to Consider when Choosing Between Them

There are several factors that need to be considered. The choice between steel and fiberglass gratings depends on various aspects such as project requirements, benefits and drawbacks of each material, slip properties, compliance with regulations, and specific needs of buyers. Let’s delve into these factors to help you make an informed decision.

Load-bearing capacity: Steel gratings have higher load-bearing capacities compared to fiberglass gratings.

Environmental conditions: Fiberglass gratings excel in corrosive environments due to their resistance to chemicals and moisture.

Maintenance requirements: Steel gratings may require periodic maintenance such as galvanizing or painting to prevent rusting, while fiberglass gratings tend to require less maintenance.

Installation ease: Fiberglass gratings are lightweight and easy to install compared to heavier steel options.

Cost-effectiveness: While initial costs may favor steel grating due to lower material costs, long-term maintenance expenses should also be considered.

Apart from the factors mentioned above, slip properties, the need for special equipment, color options, and compliance with regulations should also be taken into account. For instance:

| Slip properties | Consider whether the grating material needs to have specific slip-resistant features based on the intended application |

| Special equipment | Determine if any specialized tools or equipment are required for installation or maintenance purposes |

| Color options | Fiberglass gratings offer a wider range of color choices compared to steel gratings |

| Compliance with regulations | Ensure that the chosen grating material meets relevant safety standards and regulatory requirements |

FAQ

A. What are the key differences between steel and fiberglass grating?

Steel grating is known for its excellent strength, load-bearing capacity, and anti-slip properties. Fiberglass grating, on the other hand, offers advantages such as corrosion resistance, lightweight nature, and electrical insulation properties.

B. Which grating material is more suitable for outdoor applications?

Both steel and fiberglass grating can be suitable for outdoor applications. However, fiberglass grating’s corrosion resistance and UV-stability make it a preferred choice for environments exposed to harsh weather conditions, chemicals, or saltwater. Steel grating, with appropriate anti-corrosion treatments, can also withstand outdoor conditions effectively.

C. Can fiberglass grating replace steel grating in heavy-duty industries?

While fiberglass grating offers remarkable properties, it may not be suitable as a direct replacement for steel grating in heavy-duty industries that require maximum strength and load-bearing capacity. However, in certain cases, fiberglass grating can be utilized effectively in less demanding areas within heavy-duty industries, offering corrosion resistance and weight reduction benefits.

Remember, selecting the right grating material depends on a careful evaluation of the specific requirements, industry standards, and long-term cost considerations.

Conclusion

In conclusion, steel grating and fiberglass grating are distinct flooring options with their unique set of properties and advantages. The choice between the two depends on factors such as strength requirements, corrosion resistance, weight constraints, cost considerations, and specific application needs.

While steel grating demonstrates superior strength and versatility in heavy-duty industries, fiberglass grating shines in applications that demand corrosion resistance and lightweight maneuverability. It is crucial to weigh all these factors and select the right grating material to ensure optimal performance and safety in industrial environments.