Introduction

To keep your facility running efficiently and safely, regular maintenance of anti-static grating is key. Not only will this help you avoid costly repairs or downtime in the future, but it can also save money right now! Make sure to stay up to date with FRP grating inspection so that you receive maximum performance over time.

Find out the best practices for cleaning and repair that will keep your FRP grating in top shape. By continuing to read, you’ll gain a comprehensive understanding of how to effectively maintain your anti-static grating and maximize its longevity.

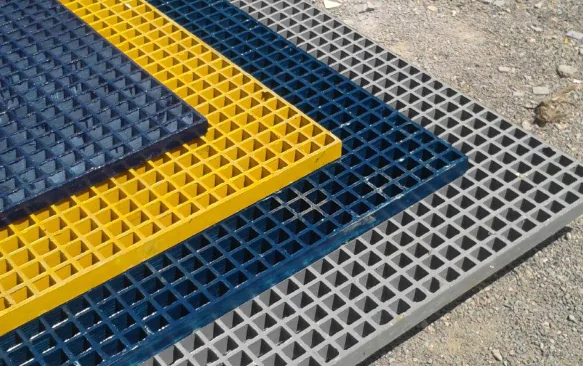

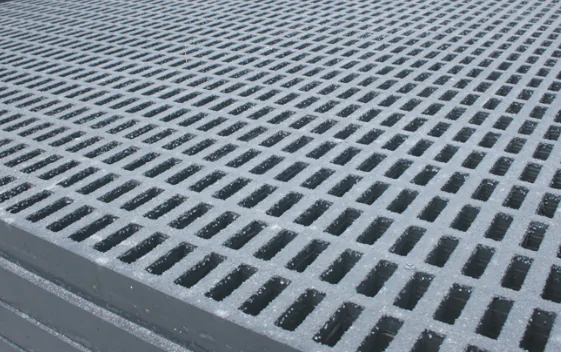

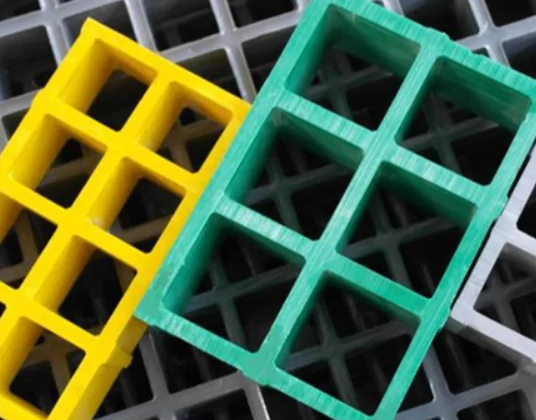

1. What is anti-static grating

An anti-static grating refers to a type of grating or grid-like structure designed to mitigate or eliminate the buildup and discharge of static electricity. It is commonly used in various industries, especially those dealing with sensitive electronic components or environments where electrostatic discharge (ESD) can cause damage or operational issues.

The purpose of an anti-static grating is primarily to provide a controlled path for the dissipation of static electricity. Static electricity can accumulate on surfaces or objects due to friction, movement, or imbalance of electric charges.

When accumulated charge is discharged suddenly, it can cause sparks or electrostatic discharges that may harm electronic devices, ignite flammable materials, or interfere with sensitive processes.

Anti-static gratings are typically made from materials with inherent or added conductive properties, such as metals or carbon fibers. These materials allow the grating to conduct electric charges and facilitate their dissipation into the surrounding environment.

By providing a conductive path, the grating helps prevent the buildup of static charges on surfaces, thereby reducing the risk of ESD-related incidents.

2. Why is it needed to maintain anti-static gratings?

Anti-static gratings protect against electrostatic discharge (ESD) by safely grounding any static electric charges that may build upon the surface. Failure to maintain these gratings could lead to their inefficient performance.

Neglecting maintenance and cleaning may result in the following consequences

- Shorter lifespan: Without proper maintenance and care, the gratings may weaken and lose their anti-static properties, eventually failing to protect against ESD.

- Increased risk of accidents: Accumulated dirt, debris, and other materials on the grating could cause slips and falls. Ungrounded static charges on the work surface could also pose a threat to workers and equipment.

On the other hand, regularly maintaining anti-static gratings offers a host of benefits, including

- Effective ESD protection: Proper maintenance ensures that the gratings are functioning effectively, providing protection against ESD.

- Longer lifespan: Cleaning and repairing any damage to the grating increases its lifespan and saves on the cost of replacement.

- Improved safety: Clean gratings lessen the risk of accidents caused by slips, falls and other injuries.

- Compliance with safety regulations: Proper maintenance helps ensure that anti-static gratings are compliant with industry regulations and standards.

3. How to clean an anti-static grating

- Use Soap and Mild Water: Begin by preparing a solution of warm water and a mild detergent or soap. Dip a clean cloth or sponge into the soapy water and gently wipe the surface of the anti-static grating. This helps remove any dirt, dust, or debris that may have accumulated.

- Rinse with Suitable Solvent: After cleaning with soapy water, rinse the grating thoroughly using clean water. This step helps ensure the removal of any remaining soap residue. It is important to use a suitable solvent, such as distilled water or deionized water, to avoid introducing impurities or minerals onto the grating surface.

- Avoid Harsh Chemicals: When cleaning anti-static gratings, it is crucial to avoid using harsh chemicals or abrasive cleaning agents. These can damage the grating material or affect its anti-static properties. Common household cleaning chemicals like bleach, ammonia, or strong solvents should be avoided. Stick to mild soaps, detergents, or specialized cleaning solutions recommended by the grating manufacturer.

4. How to repair anti-static gratings

Step 1. Check Damages:

Begin by inspecting the grating for any visible damages or areas of concern. Look for cracks, breaks, or signs of wear that may affect the performance of the anti-static grating. Identifying the extent and nature of the damage is crucial for determining the appropriate repair approach.

Step 2. Clean and Wipe:

Before proceeding with the repair, ensure that the damaged area is clean and free from debris or contaminants. Use a mild detergent or soap solution and a clean cloth or sponge to gently clean the damaged area. Rinse it thoroughly and allow it to dry completely.

Step 3. Remove Damaged Part if Possible:

If the damage is localized and a specific part of the grating is affected, you may need to remove that portion. Depending on the construction of the grating, this may involve unscrewing, unclipping, or cutting away the damaged section. Follow the manufacturer’s instructions or seek professional guidance if necessary.

Step 4. Apply Adhesive and Replace the Part:

Once the damaged part is removed, apply an appropriate adhesive or bonding agent to both the repaired area and the replacement part. Carefully position the replacement part and press it firmly into place, ensuring proper alignment with the surrounding grating. Follow the adhesive manufacturer’s instructions for application and curing times.

Step 5. Wait for Curing:

Allow the adhesive to cure as per the manufacturer’s recommended timeframe. This ensures a strong and secure bond between the repaired section and the grating. Avoid subjecting the repaired area to any stress or strain during the curing process to ensure optimal results.

Step 6. Smooth the Surface:

After the adhesive has cured, check the repaired area for any unevenness or rough edges. Use fine-grit sandpaper or a smoothing tool to carefully smooth the surface, ensuring that it blends seamlessly with the rest of the grating. Take caution not to damage the anti-static properties or integrity of the grating during this process.

It is important to note that the repair process may vary depending on the type and material of the anti-static grating. Always refer to the manufacturer’s instructions or seek professional advice for specific repair guidance. Additionally, if the damage is extensive or beyond your expertise, it is recommended to consult a professional for repair or replacement.

Conclusion

Regular maintenance of your anti-static grating (FRP grating) is crucial for protecting sensitive electronic components and preventing ESD damage. By following the provided maintenance tips and avoiding common pitfalls, you can ensure optimal equipment reliability and extend the lifespan of your anti-static grating.