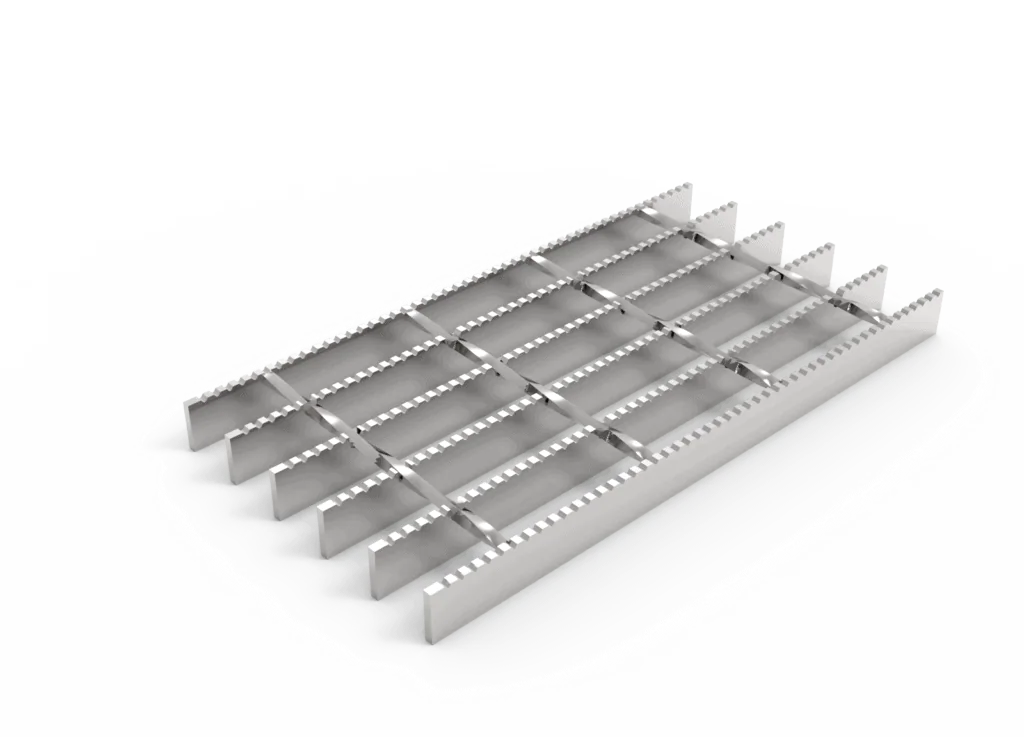

Regarding steel grating, what material is best suited for your needs? In choosing the right steel grating for your application, it’s important to know the material that is best suited for your application.

By reading this article, you can choose the appropriate steel grating for your application, which will explain many types of steel grating.

1. Different Types of Materials Used for Steel Gratings

Which type of metal is utilized in metal grating? All types of metal can be used to make metal grating. Still, the most common is carbon steel metal grating, galvanized steel metal grating, stainless steel metal grating, and aluminum metal grating. Each material has its unique benefits and drawbacks.

Carbon steel

The most popular and typically cheapest type of metal grating is carbon steel. It is strong and durable but can rust if not properly maintained.

Galvanized Steel

Galvanized steel is an excellent choice of metal grating for applications where exposure to the elements is a concern since it is covered with a layer of zinc to prevent corrosion. However, galvanized steel gratings are more expensive than carbon steel for metal grating.

Stainless Steel

The most expensive option is stainless steel, which is also the most resistant. Using it as stainless steel gratings does not corrode or rust, making it a good choice for applications where hygiene is important.

Aluminum Steel

Nearly as popular as steel, aluminum is the second most used material. Aluminum is often referred to as a “light metal” and has a very high level of strength. This metal grating is less expensive than many because it is particularly lightweight.

The Benefits of Each Material

| Carbon Steel | Also called plain steel, has different strengths including low carbon, medium carbon, high carbon, and very high carbon. Although it can rust under certain conditions, it is highly shock-resistant and therefore commonly used in construction projects. |

| Galvanized Steel | It has a zinc coating that protects against corrosion, requiring less maintenance over time. |

| Stainless Steel | Stainless steel is incredibly durable and resistant to corrosion, fire, and heat. It’s easy to work with and has a sleek aesthetic, making it a popular choice. |

| Aluminum steel | It is lightweight but strong, and its corrosion resistance makes it ideal for applications where hygiene is important. |

2. How Each Type of Steel Grating is Made

Welded steel grating VS press-locked metal grating

When it comes to metal gratings, there are two main types: welded steel grating and press-locked metal grating. The primary difference between the two is their method of manufacture.

- Welded steel gratings are created through pressure resistance welding at each intersection point of the bearing bars and cross bars, typically using twisted steel for the crossbars.

- Press-locked metal grating, on the other hand, uses pressure to flatten the crossbars where they intersect with the bearing bars, creating a stable structure that’s less likely to deform than welded steel grating. Additionally, press-locked steel grating is often less expensive than welded steel gratings.

Expanded Metal grating

Expanded metal grating is made by creating diamond-shaped patterns in a metal sheet through slits, then expanding the sheet. The resulting sheet can be flattened and cut to size to create a metal grating.

Aluminum, carbon steel, stainless steel, and other materials can be used for expandable metals, and no waste is produced during the expansion process as the sheet’s structural strength is maintained without holes being punched into it. This type of grating is often used for security measures, industrial flooring, fences, and steps.

Safety Grating

A few simple tools can be used to create safety grating, which is fairly easy. The first step is to start with a sheet of metal that has been cold-stamped. This will create small diamond-shaped protrusions on the surface of the metal.

The next step is to serrate the edges of these diamonds. This can be done with a simple grinding wheel. Finally, the safety grating can be installed on a walking surface for increased traction and safety.

3. How Each Material can be used in Various Applications

There are many different types of materials that can be used in a variety of ways. Each material has its own unique set of properties that make it perfect for certain applications.

Carbon Steel

Carbon steel is a versatile material with numerous applications. It’s a great option for construction projects because it’s less brittle and more ductile than other types of steel, providing strength and flexibility where needed.

It can also double as a safety railing to prevent falls or as a drain cover or grating in floor drains to keep the area clean and debris-free. Plus, its sleek aesthetic makes it an attractive choice for interior decor. Carbon steel’s resistance to corrosion and affordability make it a popular building material option.

Stainless Steel

Stainless steel grating is a good choice for a variety of applications because it is strong, durable, and resistant to chemicals. This makes it a good choice for a variety of applications, including those where exposure to harsh chemicals or moisture is likely. Stainless steel grating can be used in many different applications, including:

- Platforms and walkways in petrochemical plants

- Platforms and walkways in power plants

- Municipal engineering

- Food processing plants

- Hospitals

- Wastewater treatment

- High-temperature operations

Galvanized Steel

Galvanized steel is a widely used material because it’s affordable, strong, and highly resistant to corrosion. It’s often found in petrochemical plants, power plants, and municipal engineering applications as platforms and walkways.

Plus, its resilience against weather makes it ideal for outdoor uses such as fences, sheds, roofs, and steel gratings. If you’re considering galvanized steel for your project, it’s important to consider the environment in which it will be used and the product’s intended lifespan.

Aluminum Steel

Aluminum steel is a type of steel with more than 10% aluminum, making it strong and lightweight. It’s resistant to corrosion, making it ideal for various applications. For instance, it is commonly used for indoor ceilings, outdoor curtain walls, decorative purposes, and mechanical equipment maintenance platforms.

Aluminum steel is also suitable for use as metal grating in flooring, replacing traditional materials like wood, concrete, or tile. It’s often utilized in construction projects as scaffolding because it’s easy to transport, assemble quickly without tools, and lightweight.

4. How to Choose the Right Material

When choosing the right steel grating material for your needs, there are a few factors to consider.

| Used for what | Depending on whether you need it for construction projects or industrial applications, different types of steel may be better suited to your needs |

| Strength and durability | . Some materials can withstand stress, chemicals, oxidation, corrosion, and wear better than others. It’s crucial to choose the right one for the job to ensure a safe and reliable product |

| Cost | Consider your budget and try to find a cost-effective solution |

| Weight and portability | Some materials may be heavy and difficult to move around, while others are light and easy to transport |

5. Other Tips for Choosing Materials

When selecting the most appropriate material, there are a few other factors to consider.

- Firstly, think about the environment in which the material will be used. Some materials are better suited to indoor use, while others are better for outdoor use.

- Additionally, you’ll want to consider the climate and weather conditions in which the material will be used, as some materials can withstand harsh conditions better than others.

- The lifespan of the material is also important to bear in mind since some have shorter lifespans than others. You’ll need to assess how long you need the material to last and choose accordingly.

- Lastly, take into account the amount of maintenance the material will require since some materials require more upkeep than others.

Conclusion

The tips in this article can help you choose the right steel grating material for your needs. By considering the purpose of the material, the environment it will be used in, and other factors, you can make an informed decision about which type of steel is best for your project.

Additionally, these tips can help you save money and time on your next construction or industrial project.