Power plants are enormous and require a well-equipped setup to work efficiently and not cause any trouble. The power industry has certain specifications that must be incorporated at the places where power plants are operating. Among them, the use of steel grating is also an essential one.

Gratings are used for various industries ranging from mining, marine, agriculture, food, and power. However, steel gratings are pretty suitable for the power industry and can support this industry with their various benefits and features.

Why would power stations need steel grating?

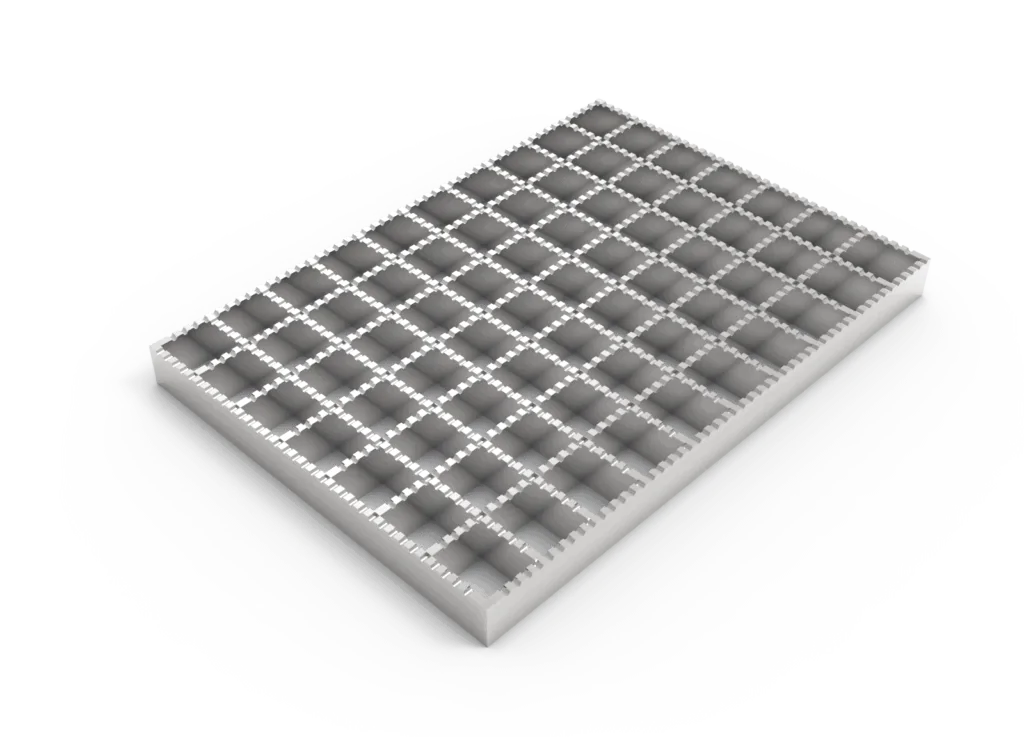

The power station is a very vast setup; it has power plants installed followed by other equipment that is quite heavy, and other support floorings might not be suitable. Hence, steel grating may be better because it offers a very high bearing capacity. Such gratings could easily bear the weight of power plant machinery.

In a power station, there are various applications of steel grating. It could be used as a platform where the equipment is installed. This allows them to handle the equipment load without fear of wear and tear.

Also, steel gratings are used in a power plant as a platform for maintenance and cleaning; reaching heights may be difficult for cleaning and maintenance. So most of the power plants have such platforms in place.

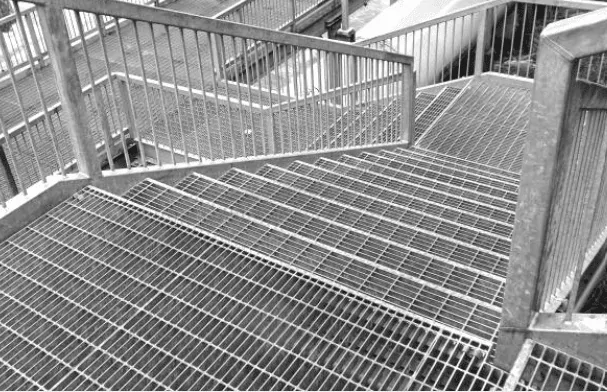

Walking platforms are also a must for the power plants because they allow reaching to the plants and look after their operations. At many power plants, platforms are made out of steel grating over which the laborers may walk and keep a check on the equipment. Also, these platforms are combined with steel grating stairs so that reaching heights becomes easier.

Features of steel grating for power plants

Power plants specifically implement steel gratings in their surroundings for many reasons. Steel gratings have features incorporated within them that prove suitable in such cases. Some of these features that make them ideal for the power industry comprise the following:

- Steel gratings are cheaper than iron platforms; hence, when it comes to looking at the economic side, they are far more beneficial as a platform for the power plant than any other material. It also has many benefits that match the low price, so the industries are better with these.

- The power plants must stay ventilated and are in an open space; hence there are two things. One is that the plant must not have any accumulated water around it. Water accumulation arises during rain, so when a steel grating is used, the water drains away from the grid present, and hence it is not accumulated.

On the other hand, this water might be stored and helps in future power generation, so the place where it seeps from might have storage containers installed to use it later, and the grating structure allows this to happen.

- Power plants need timely maintenance and must be kept away from dust; hence, when installing steel gratings, these are pretty easy to clean and maintain. So when they get dusty, they can immediately be washed in no time; hence, the power plant is also kept clean.

- Steel gratings are durable; no matter what, they don’t break easily and hence can be used for a longer time even if they broke or chipped off from any place that area could be replaced at a minimal cost.

- Installing a platform made of steel grating is very quick and easy. The platform is manufactured depending on your specifications, and it is fixed right away in no time. The best part is that it doesn’t get deformed no matter how heavyweights are subjected to it.

Tips on choosing a perfect power station steel grating

Investing in a power station steel grating is never an easy task. This will cost you because the area is quite a lot and it is also preferred to be chosen as a one-time investment. Therefore, one must try their best to have it installed after taking care of minor things, and here we have suggested some o essential tips to follow:

Material selection

When looking forward to having steel grating platforms chosen for the power plants, you must choose between the different available material options. You have either a choice of carbon steel or stainless steel.

Carbon steel is very durable and has high bearing capacity; however, it is not suitable to subject this material to highly corrosive environments. Hence if your power plant is located where climatic changes are not very harsh, it would work.

However, if your power plant is in a highly corrosive environment, you must choose stainless steel. It provides a similar level of durability and bearing of weight, and at the same time, it has a nature to stay intact in highly corrosive conditions as well.

Size of the platform

It is imperative to ensure that you have given appropriate measurements for the grating size you need. Once the platform is created, adding any further changes would be suitable. Hence, the size must always be a crucial concern when it comes to having steel grating for a power station.

The size will depend on the area and space that needs to be covered; there are walkways, platforms for keeping the equipment, and maintenance platforms, and each kind would have a different size requirement.

Finishing of steel grating

Finishing touches are evenly applied on the gratings once they are ready. This could be a galvanized grating where the grating is subjected to a surface treatment by a hot galvanizing dip. This makes it more robust and adds durability by making it capable of holding tactfully in corrosive environments.

However, sometimes, painted gratings are also used that are usually painted different colors and offer a coverage coat over the grating. Such gratings are generally considered to enhance the place’s aesthetic look since colors could be added to the grating.

Conclusion

Power stations need appropriate maintenance and something strong enough to tackle the weight and pressure it gives to the surroundings. Hence, choosing steel grating for such purposes is always the best idea, and apart from this, many shapes and layouts could easily be customized.