Working on an offshore platform presents unique safety challenges, one of which is ensuring safe walkways. How do offshore platforms ensure safe movement despite the harsh and slippery environmental conditions? This is where floor gratings come in. The unknown hero of the offshore industry, floor gratings play a vital role in safety and operations.

1. Understanding Offshore Platform Floor Gratings

Floor gratings on offshore platforms are essentially industrial-grade steel or fiberglass grates installed on the platform floor. They provide a robust and non-slip surface that ensures the safe movement of personnel and equipment. Floor gratings not only enhance safety but also facilitate the drainage of any spilled liquids, thus reducing the chances of accidents.

These strong and durable grates are usually installed in areas where there is a high risk of falling objects, slippery surfaces, or heavy foot traffic. This includes areas such as drilling decks, workover areas, production decks, and around the platform’s edges. The design of these gratings ensures maximum traction, even in adverse weather conditions.

With the complexities that working offshore brings, adopting industrial-grade floor gratings designed for such environments is not an option but a necessity. So, next time when you step on an offshore platform, take a moment to appreciate the floor under you, keeping you safe and secure. Our journey to understanding offshore platforms continues – stay tuned for more insights.

2. Types of Offshore Platform Floor Gratings

In my years of working with offshore platforms, I’ve had ample experience with a variety of floor gratings. Each type has its unique properties, usage, and benefits. In this section, I am going to share my knowledge about the common types of platform floor gratings.

A. Description of the Common Types of Platform Floor Gratings

| Steel Gratings | Constructed from a series of bearing bars and cross rods, this type is exceptionally durable and robust. It comes in different varieties such as press-locked, riveted, and welded. The most commonly used type in offshore platforms is the galvanized steel grating due to its excellent corrosion resistance. |

| Fiberglass Gratings | These are lightweight, non-conductive, and resistant to corrosion, making them a popular choice in the offshore industry. |

| Aluminum Gratings | Known for their lightweight and high strength-to-weight ratio, these gratings are often used in applications requiring significant load-bearing capabilities. |

B. Unique Features and Applications of Each Type

Let’s delve deeper into the unique features and applications of each type.

| Steel Gratings | The sturdiness and durability of steel gratings are perfect for heavy-duty applications. They are widely used in areas of the platform that require high weight-bearing capacities. Their corrosion resistance also makes them extremely durable, increasing the longevity of the offshore platform |

| Fiberglass Gratings | The non-conductive and corrosion-resistant properties make them suitable for areas prone to chemical spills or electrical hazards. Moreover, their lightweight nature makes installation and maintenance relatively easy. |

| Aluminum Gratings | They are primarily used in applications requiring light material with significant strength. They are often used in structured platforms due to their resistance to weather conditions and outstanding durability. |

3. Importance of Offshore Platform Floor Gratings

A. The Role of Floor Gratings in Safety and Efficiency

Floor gratings on offshore platforms play a crucial role in ensuring the safety and efficiency of operations. They act as the ‘ground’ for workers, helping them navigate the platform and carry out their duties with minimal risk. Crafted to endure harsh sea conditions, floor gratings offer high stability, thus reducing the chance of slips, trips, and falls. With their open design, they also allow for the easy passage of seawater, snow, or ice, maintaining a clean and unimpeded path for the staff.

In terms of efficiency, floor gratings contribute significantly. Their installation and maintenance require less time and resources than conventional flooring options. Moreover, their inherent durability and resistance to heavy load and corrosive elements make them a cost-effective and long-term solution, thereby enhancing work efficiency.

B. Ensuring Durability and Stability of the Platform

The design and materials of our floor gratings are developed after rigorous research and testing to make sure they are capable of withstanding the harshest environmental conditions. Composed of stainless steel, galvanized steel, or fiber-reinforced plastic, these gratings are highly resistant to corrosion, a common threat in the maritime environment.

Their robust construction also aids in distributing the load evenly, resulting in exceptional stability. The weight of heavy machinery and personnel is well-handled, preventing any deformation or damage, thereby contributing to the overall lifespan of the platform.

C. Preventing Accidents

Offshore platforms are inherently high-risk environments, and one of the key concerns is preventing accidents. Floor gratings present a straightforward yet effective solution. With their anti-slip surface and water drainage capabilities, they significantly are reducing risk factors like standing water and icy surfaces that could lead to slips and falls.

The transparency of the grating design also assists in detecting and preventing potential falling object hazards. By providing a clear view of the area beneath the gratings, workers can identify and remove any equipment or debris that might cause accidents.

4. Features to Consider when Choosing Offshore Platform Floor Gratings

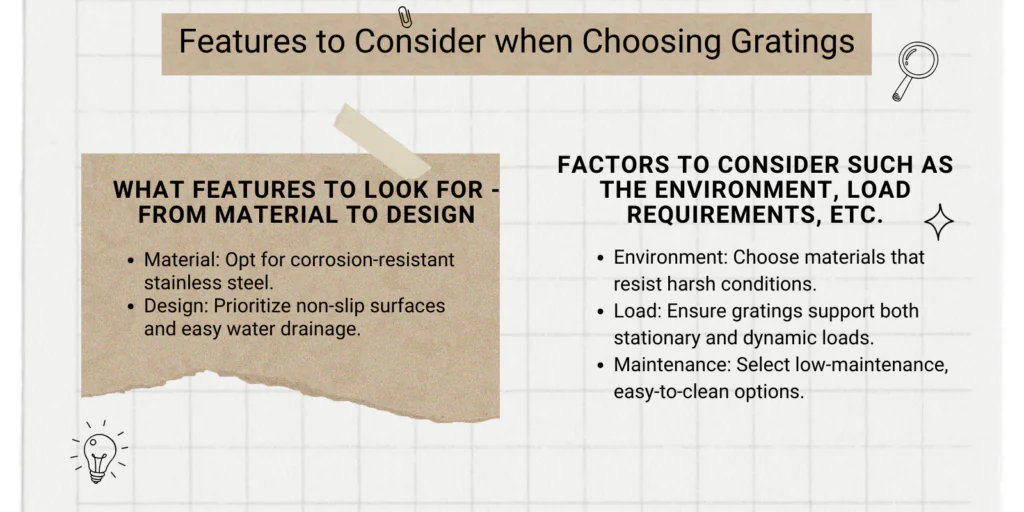

A. Guide on What Features to Look for – from Material to Design

Material is one of the first features you’ll want to consider. Here, stainless steel floor gratings are an excellent choice, as they demonstrate strong resistance to corrosion – an indispensable feature in an offshore environment. Additionally, their high strength-to-weight ratio makes them suitable for high traffic areas, thus enhancing the safety of the platform.

The design of the grating is another significant factor. For offshore platforms, you’ll want to ensure the grating has a non-slip surface to prevent accidents, even in wet or oily conditions. Moreover, the open design should facilitate easy drainage of water, thereby reducing the risk of pooling and subsequent slipping hazards.

B. Factors to Consider Such as the Environment, Load Requirements, Etc.

Over the years, one of the key things I’ve learned in this industry is that environmental conditions play a significant role in shaping the selection of floor gratings. Offshore platforms are exposed to harsh weather conditions, high humidity, and corrosive elements like seawater. Therefore, the gratings should be able to withstand these elements without deteriorating or compromising safety. For instance, materials such as stainless steel or galvanized steel offer excellent corrosion resistance, making them ideal for such settings.

Load requirements are another major factor you’ll need to account for. The grating should be sturdy enough to support both stationary loads (like equipment) and dynamic loads (like personnel or moving equipment). To ensure this, you’ll need to pay attention to the specification of the gratings, such as the span, bar size, and load ratings.

Furthermore, maintenance is an aspect that should never be overlooked. A grating that requires less maintenance would save time and resources in the long run. Hence, selecting a product that is not only durable but also easy to clean can lead to cost savings.

5. Maintenance of Offshore Platform Floor Gratings

A. Explanation on Why Maintenance is Necessary

Over years of working in the oil and gas industry, I’ve come to understand how vital the maintenance of offshore platform floor gratings is to the overall efficiency and safety of operations. These floor grating systems play a crucial role in offering a secure, slip-resistant surface that can withstand not just foot traffic, but also heavy machinery and equipment. Thus, they are continuously exposed to extreme environmental conditions, including saltwater corrosion, wind, UV radiation, and temperature fluctuations.

Failure to regularly maintain these systems can lead to corrosion, structural damage, or even failures, jeopardizing the safety of the workforce and potentially leading to expensive repairs or replacements down the road. Hence, their regular inspection and maintenance are of paramount importance for the smooth operation and longevity of these platforms.

B. Simple Tips and Recommendations for Maintainance

| Regular Inspection | A visual inspection should be carried out at least once a month. Look out for any signs of corrosion, deformation, or any damage that could compromise the integrity of the flooring. |

| Prompt Repair or Replacement | Any damaged or corroded parts of the floor grating should be promptly repaired or replaced to prevent further damage. |

| Cleaning | Regular cleaning using appropriate cleaning agents and pressure washing can help remove dirt, grease, and salt deposited on the gratings from seawater which can speed up the corrosion process. |

| Anti-Corrosion Measures | Painting or coating the floor grating with anti-corrosion materials can help protect them from harsh offshore conditions. These coatings should be regularly checked and refreshed as required. |

| Proper Installation | Ensuring proper installation of these gratings can reduce chances of early damage or failure. Always consult with professionals or refer to the manufacturer’s installation guide. |

These tips and strategies come from my extensive field experience and firsthand knowledge – they’ve proven their efficacy over time. I’ve always been committed to sharing reliable and accurate information to ensure the safety and performance of offshore platforms. With regular attention, informed action, and appropriate maintenance, you can ensure that your platform’s floor gratings continue to perform at their best for years to come.

Conclusion

Offshore platform floor gratings are essential for safety and efficiency. Their benefits are immense, from spill control to improved footing. This underscores the need for increased awareness and proper integration. Let’s champion for an industry-wide adoption of these gratings.