Introduction

Steel grating sunshade panels can provide effective sunlight control, a high level of seclusion, and a tidy aesthetic surface with the right ventilation advantages. Shade, dimming, energy efficiency, soundproofing, and protection for glass curtain walls are just a few of its features.

Do you want to know more about the different types of grating panels available, where you can use them, how to choose the right one and how long it will last? Continue reading below.

What is a Steel Grating Panel and its Benefit

A grating panel has attributes like shading, dimming, energy efficiency, soundproofing, and protection for glass curtain walls, among others. It was strong and resistant to corrosion. It has a beautiful and airy architecture that is made of diverse materials on different panel sizes. It is simple to install and requires no upkeep.

The different Types of Steel Grating Panels available

- Standard Grating Panels

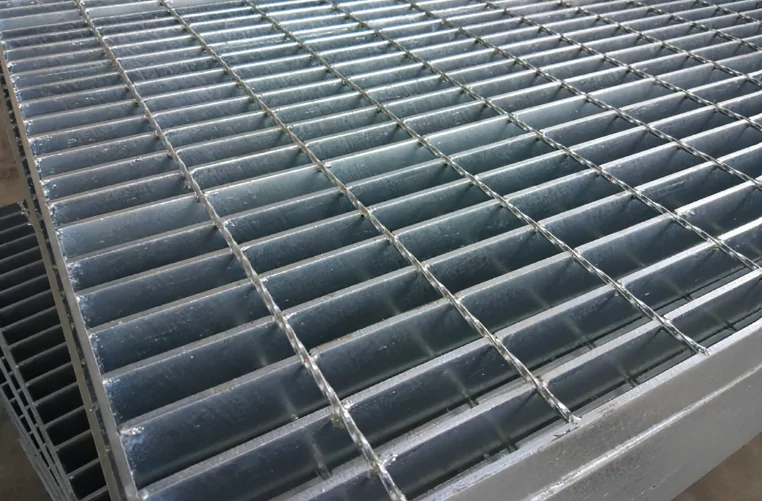

These panels are made of mild steel and can be non-galvanized. It has open ends and twisted cross bars. It is also can be plain or serrated surface treated. The panels are constructed using bearing bars that are perpendicular crossbars that are welded, swage-locked, or press-locked together to form the structure.

Obtainable in a range of bearing bar spacings, heights, and thicknesses, it is used for various load-bearing applications that require open-spacing structures made of lightweight, strong, and durable metals for maximum ventilation benefits.

- Flooring and Platform Panels

It is created by welding steel bars and flat at specific intervals. It undergoes many operations, including cutting, opening, and edging. The goods benefit from high strength, lightweight, high bearing, easy loading, and other features. The product has outstanding anti-corrosion thanks to the hot-dipped zinc coating.

- Perforated Steel Bar Grating Panels

These vertical sun shade panels have a standard, 5 mm thick edge bar for stability and rigidity. The mesh width and louver height can be modified to alter the rate of ventilation or shade. Metal bar grating with smooth perforated sheets is frequently used for cladding, shielding, or facade panels. Bar grating with a checkered perforated plate is used for an outdoor shade to create non-slip stair steps.

- Steel Bar Grating Panels with a press lock

The panels are made by press-locking bearing bars in pressure lock grating to parallel crossbars. Serrated grating is a hard, slip-resistant grate that requires little maintenance, has high strength, and outstanding performance, and is easy to clean. It can support weights from vehicles or pedestrians and provide effective solar control.

- Infill Steel Grating Panels

These outdoor-use panels are comprised of stainless steel and aluminum, which gives a lighter weight and superior corrosion resistance. Abrasion blasting, chemical treatment, or electropolishing are all options for stainless steel infill steel grating panels. It comprises several parallel metal bars with crossbars that are perpendicular for stability.

- Plain Type Panels

This type of panel is formed as a smooth visual surface bar and a predetermined distance is made by welding or pressure locking of aluminum. The bearing bars can be a flat type, serrated type, or bar type. It is energy-saving, good for sound insulation, building an awning, and regulating heat.

Where can Steel Grating Sunshade Panels be used

A sunshade panel can be used over office building doors, windows, and balconies as it has effective solar control allowing maximum ventilation benefits. It can be applied over

- the office building windows

- above the home’s windows

- over the home’s front door

- outside cover

- glass curtain wall

- over the balcony

How to Choose the Right Steel Grating Panel for Your Needs

To choose the right panel to fit your needs, here are the things you need to look out for:

Select the Banding

The open ends of the grating panels may be banded to lend further transverse stiffness and a finished architectural effect. This is accomplished by grating the cut ends of the welded bar to a flat bar roughly the same size as the bearing bars.

Look for the Layout

The 24 inches and 36 inches broad panels used for stock grating are the common sizes. These sizes allow for efficient planning and waste reduction when they are produced to your exact specifications.

Check the Attachment of the Gratings

The best, most durable installation is to weld panels to the structure that supports them. All grating must be firmly attached in place.

Select the Clips

The flange holding the panel together is connected by friction by mechanical fasteners located on the upper surface of the grating. These clips are easy to install without drilling or welding.

Defining Span

This is the overall length of the grating panels when they are delivered to the customer, measured parallel to the bearing bars.

Measuring the Size

The total dimension of the grating panel, measured perpendicular to the bearing bar span, is known as the panel width. Grating panels can easily be supplied in a variety of widths to fulfill the requirements of any application. Typically, they are manufactured and stocked in nominal widths of 24 inches and 36 inches. Additionally, customing widths can be created in a shop while maintaining any required tolerance.

How long will a Steel Grating Panel Last

A panel will last as no additional support will be necessary as long as the hole only removes a maximum of one-third of the width of each grating panel. To make the best use of grating panels, some steel gratings should be preserved from center to center of supporting material.

Deflections will be further decreased if grating panels are put over several spans. To prevent the grating panel from toppling over, grates used in this manner must be secured to a minimum of two supports and have a minimum of three hold-down clips at each interior support for a perfect solution especially for your window and door shade.

Conclusion

I hope this article gave you an insight into a sunshade panel and how it works. From standard type to infill panels made of steel and aluminum, make sure you choose the right product that fits your needs on your steel gratings.