Introduction

Galvanized steel gratings are available in several types, each of which has its advantages and disadvantages. The most commonly used type is surface-mount galvanized steel grates, which offer excellent corrosion resistance and require minimal maintenance.

This type of grating resists wearing from foot traffic, making it ideal for public spaces such as sidewalks and parking lots. All types of galvanized steel gratings have an attractive finish that will last through the years.

The 4 basic types of stainless steel gratings used in general production are:

- Welded galvanized steel grating

- Press-locked galvanized steel grating

- Hot-dipped galvanized steel grating

- Cold galvanized steel grating

In this article, we will identify each of the types’ qualities, advantages, and applications.

What is galvanized steel grating?

Galvanized steel gratings are grids of metal bars that have been coated with a zinc alloy layer. This protective coating helps to prevent rust and corrosion, making them a popular choice for outdoor applications. They are available in many sizes and styles, ranging from small mesh grates to large heavy-duty walkways.

A variety of finishes can also be applied to galvanized steel gratings for extra protection or aesthetics. These grates are often used in industrial environments, on construction sites, and in commercial spaces such as retail stores or restaurants where safety is an important consideration.

With their strong build quality, galvanized steel gratings can provide years of reliable service with minimal maintenance.

4 Common types of galvanized steel grating

- Welded galvanized steel grating

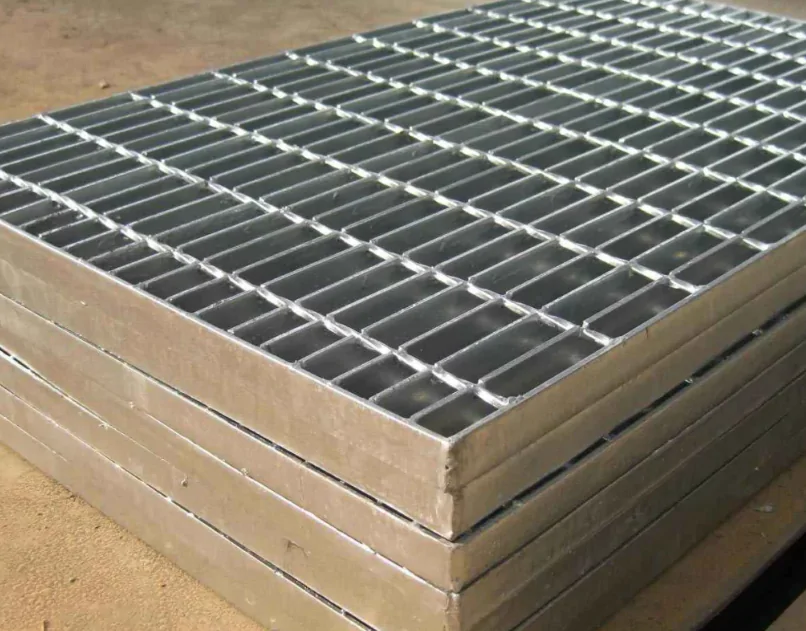

Welded galvanized steel grating is made up of load-bearing bars and cross bars that are fusion welded together. The load-bearing bars are spaced apart at certain intervals to create a rigid structure, while the cross bars overlap one another to provide support, stability, and strength.

In addition to providing superior structural integrity, welded galvanized steel grating also offers anti-skid and anti-corrosion protection. It is often used in applications where durability and longevity are key requirements such as bridge decks, walkways, industrial flooring, stair treads, and more.

Welded galvanized steel grating is an economical alternative for many construction projects due to its low maintenance requirements compared to other materials.

- Press-locked galvanized steel grating

Press-locked galvanized steel grating is a type of metal grating that is manufactured by pressing the cross bar into the bearing bar. It is available on smooth surfaces or serrated surfaces for enhanced slip resistance.

The galvanizing process provides corrosion resistance and durability, making it suitable for outdoor applications such as stair treads, walkways, and security fencing. This type of grating is also easy to install and can withstand heavy loads.

It is highly customizable in terms of finishes, size, and shape, making it a great choice for many architectural projects. Its lightweight construction makes it ideal for areas where weight restrictions are a primary concern.

- Hot-dipped galvanized steel grating

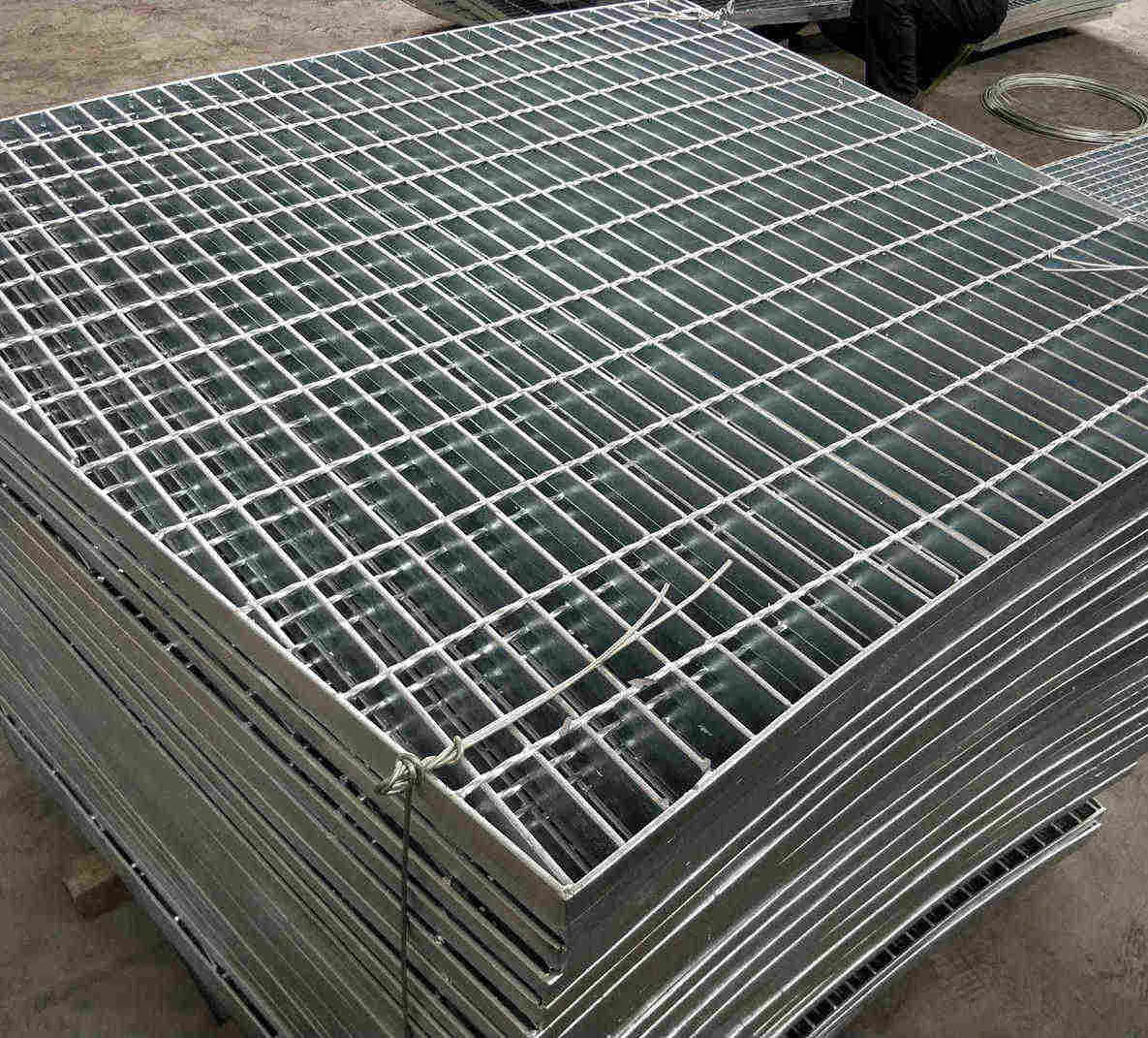

Hot-dipped galvanized steel grating is a type of steel structure with superior corrosion resistance compared to other types of steel structures. It is composed of two parts: a flat steel sheet and a crossbar, which are connected using welding or pressure locks.

The flat sheet has small strips called bearing bars that are spaced out evenly across the surface, while the crossbar runs perpendicular to the bars at regular intervals, creating an open grid-like pattern. In addition, there is usually a coating on top of the grating for added protection against corrosion. This coating can be either hot-dip galvanizing or epoxy painting depending on the application.

- Cold galvanized steel grating

Cold galvanized steel grating is a kind of heavy-duty grating that is specially designed to be used in industrial and commercial applications. It is manufactured using hot-dip galvanizing, which gives it superior strength and durability compared to other types of grating.

This type of grating can handle high loads and provides outstanding resistance to corrosion, making it ideal for outdoor applications such as walkways, steps, decks, driveways, and more. Its unique design also allows it to provide high levels of slip resistance while still providing an aesthetically pleasing look that won’t detract from the overall beauty of a facility or public space.

The applications of galvanized steel grating

Galvanized steel grating can be used in a variety of applications, such as stair treads, walkways, drainage systems, and more. It is also commonly used in commercial kitchens due to its resistance to corrosion and fire. In outdoor applications, galvanized steel grating can be used for decking or fencing needs.

Additionally, it can provide extra support for trees or other vegetation in landscaping projects. One of the most popular uses for galvanized steel grating is drain covers or trench covers; these are especially useful in areas that experience a lot of foot traffic or heavy-duty equipment movement.

Conclusion

Galvanized steel grating offers a long-lasting, cost-effective solution for many applications. Its superior corrosion resistance, high strength, and durability make it an ideal choice for a variety of industries. With proper maintenance and installation procedures, galvanized steel grating can provide years of reliable service.

Companies in the construction, manufacturing, and other industries can benefit from its use as a safe and reliable material for walkways, stair treads, and other applications. It is also becoming increasingly popular due to its environmentally conscious characteristics since it can be recycled or reused with ease when plans change.

While traditional materials like wood may be less expensive initially, the long-term costs associated with frequent replacement makes galvanized steel grating an attractive option for big industrial companies.