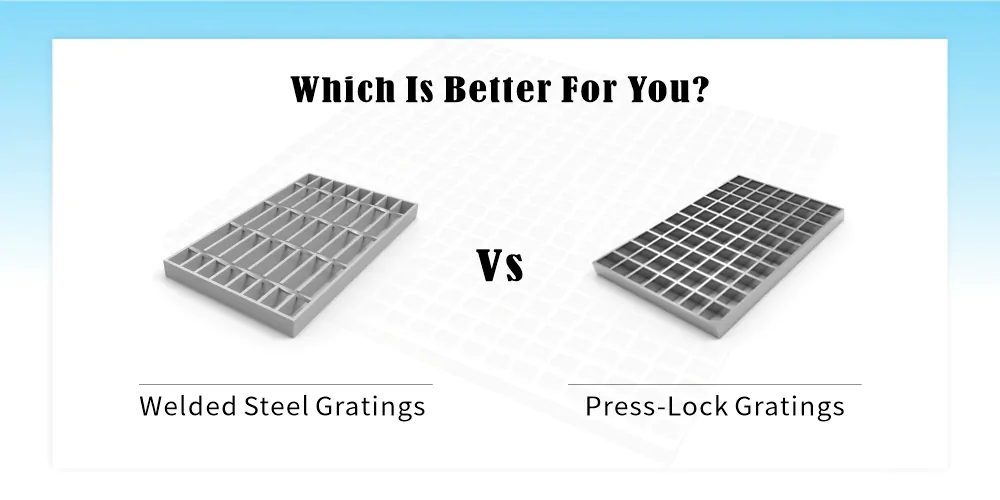

Are you wondering about the best type of steel grating to use for your next project? Struggling to decide between welded and press-lock grating? You’re not alone. These are problems faced by countless others in the industry. Understanding these two types of steel grating could make an enormous difference in terms of cost, durability, and overall project quality.

Let us shed some light. First up, welded steel grating is primarily used for industrial purposes. It is known for its strength, and reliability, and is most commonly used for heavy-duty applications. On the other hand, press-lock grating, features interlocked notches enabling easier assembly without welding, making it perfect for more design-oriented purposes.

Want to know more about welded and press-lock steel grating? Stay tuned as we delve deeper into the specific characteristics, benefits, and uses of each type, aiming to give you a well-rounded understanding to help you make the best decision for your specific project needs.

1. Understanding Steel Grating

A. Definition and Uses of Steel Grating

Steel grating is a ubiquitous construction material, typically made from a series of cross rods and bearing bars. It’s widely used in industrial areas for its strength, durability, and ability to permit passage of light, air, and water. Commonly, you can find steel grating in factories, warehouses, or public utility facilities.

B. Importance of Selecting the Right Type of Steel Grating

Choosing the appropriate steel grating significantly impacts the performance and longevity of the structure. By correctly identifying the type of load (either static or dynamic) the grating is expected to bear, potential problems like grating malformation or even structural collapse can be avoided. Therefore, it is essential to understand the various types of grating available and to select the best suited for the intended use.

2. Evaluating Welded Steel Grating

A. Description and Manufacturing Process of Welded Steel Grating

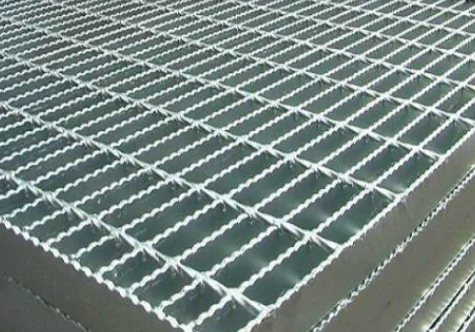

Welded steel grating is a particularly popular type of steel grating. It’s made by joining the cross rods and bearing bars together under high pressure and heat. This process results in a one-piece panel with a surface that’s both durable and slip-resistant, providing a high degree of safety.

B. Pros and Cons of Welded Steel Grating

| ✅ Pros | High strength, Light structure, Non-slip grid surface, Easy installation |

| ❌ Cons | Potential rusting at welding spots leading to structural weakness, Lower aesthetic appeal compared to other types of grating |

Welded steel grating offers several advantages such as high strength, light structure, a non-slip grid surface, and easy installation. However, despite these benefits, it is not without its cons. For instance, over time, the welding spots might rust, leading to structural weakness. Furthermore, compared to other types of grating, its aesthetic appeal is relatively low.

C. Best Applications and Uses for Welded Steel Grating

Because of its robustness, welded steel grating is well-suited for many applications. For example, its non-slip surface makes it ideal for platforms and stair treads in industrial settings. Moreover, due to its high light, air, and water permeability, it’s particularly advantageous in drainage systems, ventilation shafts, and other similar applications.

3. Evaluating Press-Lock Steel Grating

A. Description and manufacturing process of press-lock steel grating

Press-lock steel grating is a highly versatile and durable material, commonly used to build flooring, stair treads, sun shades, and drainage covers amongst others. It is designed to withstand pressure and to provide a safe and secure surface to walk or work on.

The manufacture of press-lock steel grating is a specialized process that involves high levels of precision and quality control. It begins with the selection of high-grade steel which is then cut into bars.

These bars are secured in place using a hydraulic press that interlocks the cross bars into the bearing bars, creating a robust and intertwined grid pattern. Thereafter, the steel grating is galvanized for enhanced corrosion resistance.

B. Pros and Cons of press-lock steel grating

| ✅ Pros | High strength, durability, good load capacity, high stability and enhanced safety |

| ❌ Cons | High initial cost, installation requires experience |

Like any material, press-lock steel grating has its strengths and weaknesses. On the positive side, it is known for its strength and durability. It is able to support heavy loads without deformation, making it ideal for use in industrial settings or high-traffic areas.

Moreover, its interlocking design offers high stability and slip resistance, enhancing safety on the worksite. It is also relatively easy to install and maintain, and its galvanized coating offers a high level of resistance to corrosion and abrasion.

On the downside, the initial cost of press-lock steel grating may be higher than other types of grating, which could be a barrier for some projects. Less experienced installers may also find it harder to install due to its interlocking system. Additionally, heavy vehicular traffic or extremely high loads may cause deformation over time.

C. Best applications and uses for press-lock steel grating

Press-lock steel grating is a highly versatile product that finds use in a wide range of applications. Due to its strength and durability, it is often used in industrial settings, such as walkways in manufacturing plants or platforms on construction sites. Its slip-resistant surface and ability to drain water quickly make it ideal for use as flooring in wet environments, such as pool sides, marinas and docks.

In architectural applications, it’s commonly used to make sun screens, fences, and partitions due to its aesthetic appeal and functionality. Thanks to its robustness and corrosion-resistant properties, it’s also suitable for use in wastewater treatment plants or other corrosive environments.

In conclusion, press-lock steel grating is an excellent choice for anyone in search of a strong, durable, and functional material for a wide array of applications.

4. Head-to-Head Comparison: Welded Steel Grating vs Press-Lock Steel Grating

A. Comparison of Strength and Durability

The strength difference primarily lies in the construction methodology. In the press-locked grating, the cross bars are cold-formed and interlocked with the bearing bars under high hydraulic pressure.

This pressure-forged process creates a single-piece grating panel with a strong mechanical interlock. The resulting structure is much more stable under load and vibration, giving press-locked grating its superior strength.

In contrast, welded steel grating is made by simply welding the cross bars onto the bearing bars. Although this method creates a robust product, the junctions where the bars meet are more susceptible to breakage under heavy loads or continuous vibrations. This can lead to a potential weakening of the overall grating over time.

Additionally, in my personal experience working with both types of gratings, press-locked gratings have consistently shown greater resistance to deformations under heavy loads. This is a testament to their superior strength and a reason why they are often preferred for applications where durability and resilience are paramount.

Therefore, both from a technical perspective and from practical experience, press-locked steel grating shows greater strength compared to welded steel grating.

B. Comparison of Cost-effectiveness

Welded steel grating is typically cheaper than press-locked grating due to a simpler manufacturing process and more efficient use of materials.

Regarding the manufacturing process, welded steel gratings are produced by welding the cross bars into the bearing bars. This method is relatively straightforward and does not require specialized machinery, which allows for mass production at lower costs.

On the other hand, the production of press-locked grating involves pressing cross bars into the bearing bars under high pressure, a process that necessitates specialized hydraulic machinery and contributes to higher production costs.

In terms of material usage, welded steel gratings usually use less material as the welding process effectively joins the bearing bars and cross bars together, thereby eliminating the need for any excess material.

Conversely, press-locked gratings require additional material to account for the displacement when the cross bars are pressed into the bearing bars, leading to an increase in material usage and potential waste, and thus increasing the overall cost.

When taking both the manufacturing process and material utilization into account, it becomes clear why welded steel grating tends to be a less expensive option than press-locked grating.

C. Comparison of Ease of Installation and Maintenance

Evaluating the ease of installation and maintenance, welded steel grating typically requires professional installation due to the welding process. This can add to the overall cost and timeline of the project. In terms of maintenance, welded grating tends to be easier to maintain due to its resilience to damage.

Press-lock steel grating, on the other hand, boasts ease of installation as one of its main advantages. The interlocking method allows for quicker and more straightforward installation, often reducing the need for specialized labor. However, the maintenance for press-locked grating may be slightly more regular due to its construction method and potential for surface wear.

In conclusion, both welded and press-lock steel gratings offer unique benefits and should be chosen based on the specific requirements of the project, whether it be strength and durability, cost-effectiveness, or ease of installation and maintenance.

5. Factors to Consider When Choosing Between Welded and Press-Lock Steel Grating

Making a choice between welded and press-lock steel grating involves careful consideration of several factors. Understanding these factors will not only help you make an informed decision but also ensure that your chosen steel grating meets your specific needs and requirements. The key factors to consider include:

A. Environmental Conditions

The environmental conditions where the steel grating is to be used should be one of your main considerations. These conditions include weather patterns, potential exposure to corrosive elements, the anticipated traffic, and the average load the grating should bear.

For instance, if the steel grating is intended for an area with high traffic or heavy loads, welded steel grating is highly recommended due to its superior strength and durability.

B. Budget Constraints

Budget considerations are crucial when deciding between welded and press-lock steel grating. It’s important to balance the upfront cost with the long-term value. While welded steel grating may be more expensive initially, it often proves more cost-effective in the long run due to its durability and low maintenance requirements.

On the other hand, press-lock grating might be a more affordable solution for projects with tight budget constraints.

C. Specific Project Needs and Requirements

Lastly, take into consideration the specific needs and requirements of your project. This includes factors such as the desired appearance, the ease of installation, the need for maintenance, and the safety features.

For instance, if aesthetics are a priority, you may want to consider press-lock grating, which offers a smooth and polished appearance. Alternatively, for projects requiring a rugged and heavy-duty solution, welded steel grating may be the better option.

In conclusion, the choice between welded and press-lock steel grating should be based on the specific context and needs of your project. By considering the environmental conditions, your budget, and the specific project requirements, you would be well-positioned to make an informed and appropriate choice.

6. Where To Buy Welded Or Press-Locked Steel Gratings?

You can purchase welded steel bar grating or press-locked steel gratings from a variety of manufacturers and suppliers. There are many companies that specialize in the manufacture and sale of steel gratings. Here are a few examples:

1. SUNJ GRATING LIMITED

It is a leading manufacturer and supplier of steel bar grating in China. In addition to weld and press-lock gratings, they also offer other products, such as handrails, stair treads, and more.

2. Steel Grating Ltd

This UK-based company specializes in the manufacture and sale of steel bar grating. They offer a wide range of products, including welded, press-lock, and swaged gratings. Their website is easy to use and provides a lot of helpful information.

3. Webforge

Webforge is an Australian company that specializes in the manufacture of steel gratings. They offer a wide range of products, including welded steel gratings, press-lock gratings, and more.

4. Ohio Gratings

Ohio Gratings is a leading manufacturer and supplier of steel bar grating in the United States. In addition to weld and press-lock gratings, they also offer other products, such as handrails, stair treads, and more.

The above companies are just a few examples of where you can purchase welded or press-locked steel gratings.

Conclusion

So, what’s the verdict? Which is better for you- welded steel gratings or press-lock gratings? The answer really depends on your needs and what you are looking for.

If you need something that is durable and can withstand a lot of wear and tear, then welded steel gratings are probably your best bet. However, if you are looking for an easy installation with less hassle, press-lock gratings may be a better option for you.

No matter what type of grate you choose,SUNJ Grating Limited is here to help make the process as simple and headache free as possible.

Have any questions about which grate would be best for your specific application? Contact us today and let one of our experts help you choose the perfect grate for the job.