Natural gas extraction is a very detailed and complex process and involves various such aspects that lead to being present in the structure when it comes to its extraction. A gas plant is equipped with many pieces of equipment, massive pipes, drilling machines, and extractors that require sufficient support in the form of a platform.

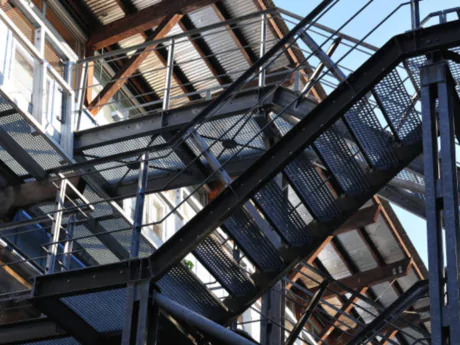

Apart from the platform reaching pipes and machinery to carry out operations, a gas plant also needs sufficient walkways, stairs, and ventilation platforms that keep the surroundings intact and well-ventilated.

The heat needs to dissipate from a gas plant because accumulation proves to be harmful to the ones who spend time working there. Therefore gas plants are also equipped with steel gratings to add support and ventilation to the structure.

Applications of steel grating in a gas plant

Steel grating is used in a gas plant in various ways, several purposes are served by steel grating in the gas extraction industry, and some of these applications are discussed below:

- Operational platforms are manufactured by way of steel grating, and workers efficiently work here and move around while at work. These steel gratings are pretty safe and secure, so when workers move around, there is no risk of falling off or breaking the platforms.

- To reach the platforms in the upper areas, stairs are required in a gas plant, and when it comes to steel gratings, these gas plants might have stairs made out of steel gratings. These are primarily serrated steel gratings as they have a rough surface and protect from falling off.

- Ventilation is one of the major concerns in a gas plant. In case there is leakage, it is imperative to have sufficient ventilation so that the people working in plants don’t feel suffocated. The steel gratings are manufactured in a way that they have spaces open, and hence the grid-like structure supports ventilation.

What features make steel gratings suitable for a gas plant?

Steel gratings are widely popular, and several reasons make it a suitable choice to consider when it comes to being used in a gas plant; some of these critical features comprise of the following:

Longer lifespan

The lifespan of steel grating is longer; hence, when implemented in a gas plant, irrespective of the pressure, the load of equipment, and the harsh conditions, it can stay intact and durable in the long run. So, this one-time investment proves to be a better choice for gas plants.

It also doesn’t corrode rust, and hence such properties make it a suitable choice for various industries.

Holds significant weight

The strength of steel grating is one factor that counts a lot, especially for industrial use. So, the strength of a steel grating is very high, and therefore the weight of pipes and equipment can easily be held by it in the longer run. This may not be possible for other kinds of flooring and platforms.

Offers ventilation

Ventilation is crucial in a gas plant, it is subjected to gas extraction, and therefore the problem of heat release is quite common. Therefore, choosing steel grating is beneficial since it helps in ventilation and heat dissipation, which is an added advantage for such plants.

Easy to clean and maintain

The steel gratings are easy to clean. You can wash them immediately whenever you feel it is getting dusty and needs a wash. On the other hand, the maintenance costs for such gratings are minimal because of their simple layout and structure. So, no time and money is wasted when such gratings are installed in a gas plant.

Safety for workers

Steel grating platforms are safe; they don’t slip, they don’t chip off, nor do they break. On the other hand, they can handle the weight, and side panels may be created using the same grating as a fence. This entire structure is relatively safe for the workers working on these platforms and moving around.

Choices of steel grating for a gas plant

When it comes to looking for steel grating for a gas plant, three common choices are suitable to opt for, and these are discussed below:

Welded steel grating

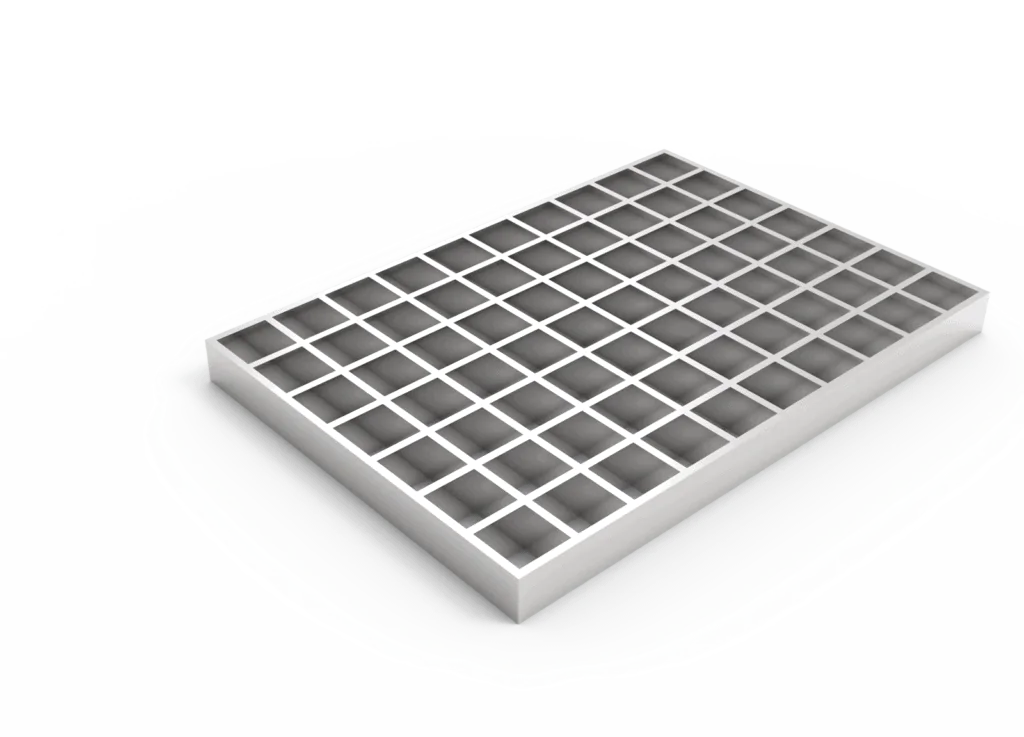

Welded steel grating has a frame on the sides and a grid in the middle. All of the steel bars are fused to perfection. This kind of steel grating structure is offered in carbon steel and stainless steel and proves suitable in every aspect. Each material has its properties, but this structure can be created in either option.

Press locked steel grating

In a press-locked steel grating, the bars are pressed into one another to create a grid-like structure. This kind of grating is commonly used in making platforms and walkways. These are primarily available in two materials: low-carbon steel and stainless steel.

Dense steel grating

Dense steel grating is a steel grating but has a spacing between its bearings bars of less than 25mm. This is usually made in a customized order and is a suitable choice for gas plants. It is also a good choice for platforms situated at a high altitude. It is offered in carbon or stainless steel and, if required, in alloy steel.

Apart from the different choices of steel grating in their making, there is also a choice in finishing. The buyers may get their gas plants either a galvanized grating subjected to a layer of hot galvanization. Also, the oil plants even require painted steel gratings depending on the requested color.

A plain steel grating or a serrated steel grating is also a choice; most oil plants tend to have a blend of both kinds, where the serrated grating is used for the stairs to protect from slipping.

Conclusion

Steel gratings tend to serve all industries irrespective of the nature of their business. Some or the other way, steel grating, may offer a very safe and durable structure to various areas. Similarly, a gas plant is also a susceptible and complex industry, and the presence of steel grating here is equally important.

Therefore choosing to implement steel grating in a gas plant in various ways could be a better approach to safety and ease.