Introduction

Installing steel grating can be a daunting task. This comprehensive guide provides everything you need to know to get the job done right, from choosing the right type of grating to installing it in accordance with safety regulations.

With this guide, you’ll be able to install your steel grating quickly and easily, ensuring a safe and sturdy surface for your project. Happy installing!

There are three main methods to install the steel gratings

| Cons | Pros | |

| By welding the steel gratings to the support structure | Requires special equipment and training, and can be time-consuming | The most secure method of attachment and produces a very strong bond between the grating and the support structure |

| Using bolts to secure the steel gratings | Must be regularly checked to ensure they are tight and secure | Quick and easy to install |

| Using clamps to secure the steel gratings | Need to be checked regularly | Quick and easy to install, do not require regular maintenance. |

How to install steel grating

First, you need to select the right type of steel grating or stainless steel gratings for your project. Then, consider the size, weight, and spacing of the grating to be installed.

Don’t worry; below, we will explain in depth how to install steel grating or heavy duty steel gratings, providing a step-by-step guide that will make the job easy and straightforward. Let’s get started!

1. Select The Right Type Of Grating:

To ensure that your grating will serve its purpose well and last for a long time, you must first select the right type. There are three main types of steel grating:

* Welded Grating: This is made by welding the bearing bars and cross bars together at their contact points. It is the most popular type of grating due to its high strength, durability, and ease of installation.

* Riveted Grating: This type is made by riveting the bearing bars and cross bars together at their contact points. It is a less popular option due to its lower strength and durability, but it can be installed more quickly than welded grating.

* Press-Locked Grating: This type is made by locking the cross bars into the bearing bars with a high-pressure press. It is a good option for areas where welded or riveted grating might be damaged by impact.

2. Measure The Space:

Once you have selected the type of bars grating you need, you must measure the space in which it will be installed. This includes the length, width, and depth of the area.

It is important to be as accurate as possible when taking these measurements, as an improper fit can cause problems down the line.

3. Choose The Right Size Grating:

Now that you know the space in which the bars grating will be installed, you can choose the right size. There are two main factors to consider when selecting the size of your grating:

* The Load-Bearing Capacity: This is determined by the type of grating you have selected. Welded and press-locked gratings can bear heavier loads than riveted gratings.

* The Amount Of Space You Have: Once you know the load-bearing capacity you need, you can select a grating that will fit in the space you have measured. Remember to leave enough room for the installation process.

4. Consider The Weight And Spacing Of The Grating:

The weight and spacing of the grating must be taken into account when choosing the size and type of grating for your project. The weight is determined by the material of the grating and the thickness of the bearing bars.

The spacing is determined by the cross-sectional area of the grating.

5. Install The Anchors:

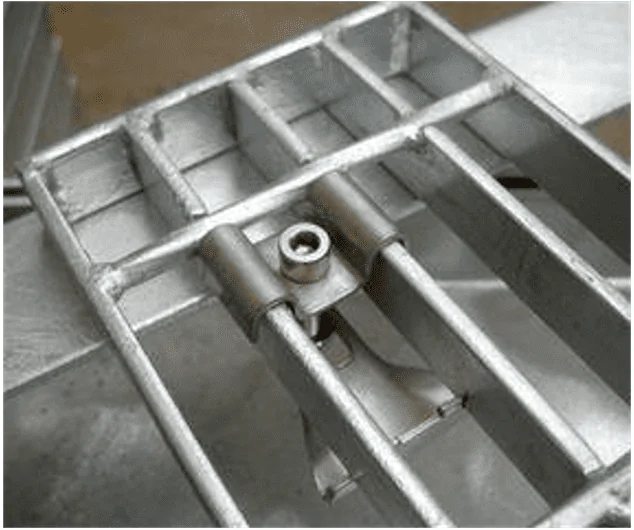

Before installing the grating, you must first install the anchors. These will ensure that the grating is securely attached to the underlying structure. There are three main types of anchors

| Welded-On Anchors | These are the most common type of anchor. They are welded onto the grating before it is installed. |

| Clip-On Anchors | These are attached to the grating after it has been installed. They are less common than welded-on anchors but are easier to install. |

| Bolt-Down Anchors | These are also attached to the grating after it has been installed. They provide the best connection between the grating and the underlying structure but can be more difficult to install than clip-on anchors. |

6. Position The Grating:

Once the anchors have been installed, you can position the grating in its desired location. This is best done with two people, as the grating can be heavy and unwieldy.

7. Secure The Grating:

Once the grating is in position, you must secure it to the anchors. This is done by welding, bolting, or clipping the grating to the anchors.

8. Trim The Edges:

If necessary, you can trim the edges of the grating to fit your space. This can be done with a power saw or a hand tool such as a hacksaw.

9. Install Edge Banding:

If desired, you can install edge banding on the exposed edges of the grating. This will give the grating a finished look and help to protect it from damage.

10. Inspect The Grating:

After installation is complete, you should inspect the grating to ensure that it is secure and properly installed. Look for loose fasteners, damaged edges, or other problems. If any problems are found, they should be corrected before use.

How To Measure Steel Grating?

It is important to be as accurate as possible when taking measurements for steel grating, as an improper fit can cause problems down the line. Below are some tips on how to measure steel grating:

Prepare the necessary equipment: You will need a measuring tape or ruler, a level, and a notepad or spreadsheet for recording measurements.

Determine the dimensions to measure: Identify the key dimensions you want to measure on the steel grating. This could include the length, width, thickness, and bar spacing.

Measure the length, width and bar spacing: Use a measuring tape or ruler to determine the overall length, the width of the steel grating and the distance between adjacent bars. Ensure that the grating is properly aligned and level during measurement.

Measure the thickness: Using a caliper or a micrometer, measure the thickness of the steel grating. Take multiple measurements at various points across the grating and calculate the average thickness.

Repeat and verify: To ensure accuracy, repeat the measurement process on multiple sections of the steel grating. Verify that the measurements are consistent and representative of the entire grating.

It’s important to note that steel grating measurements may vary depending on the specific design and application requirements. Consult relevant industry standards, guidelines, or consult with experts if there are any specific measurement protocols to follow for your particular use case.

How To Cut Steel Grating?

Cutting and welding steel grating is not as difficult as it might seem. With the right tools and a little practice, you can cut and weld steel grating like a pro. Here are some tips on how to do it:

| Choose the right tools | choose the right tools for the job. You will need a power saw with a carbide-tipped blade, a welder, and a grinder. |

| Measure and mark the grating | Before you start cutting, you will need to measure and mark the grating. This will ensure that you cut it to the correct size. |

| Cut the grating | Once the grating marked, you can start cutting it. Be sure to use gloves and eye protection when doing this. |

| Band the edge(optional) | After cutting the grating, you could choose to band the sharp edge by welding steel bars. This would strengthen the grating. |

| Grind the grating | Grind the welds smoothly. This can be done with a grinding wheel or a hand-held grinder. |

Conclusion

Installing steel grating can be a daunting task. However, by following this comprehensive guide, you should have no problem completing the installation process.

If you have any questions or run into any problems, please don’t hesitate to reach out to us at chinagratings.com for assistance. We would be happy to help!