Introduction

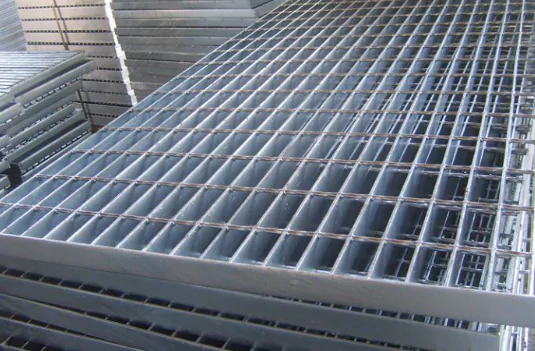

Cutting steel grating requires the right tools and techniques to ensure a precise and efficient job. If you’re wondering whether a table saw can get the job done, this article will help you find the answer.

Discover the key factors to consider when using a table saw for cutting steel grating. By the end of this article, you’ll have a better understanding of whether a table saw is the right tool for your next steel grating cutting project.

1. Necessary preparations

Safety Glasses

Wear safety glasses with side shields or goggles to protect your eyes from flying debris, metal fragments, or sparks that may be generated during the cutting process.

Gloves

Use heavy-duty work gloves made of materials such as leather or cut-resistant fabric to protect your hands from sharp edges and potential cuts.

2. Fators to consider

Cutting Blade

Selecting the appropriate blade type is crucial for cutting steel gratings effectively. Consider using a cutting wheel or a diamond blade specifically designed for cutting metal. These blades are typically more durable and have teeth or edges that can handle the toughness of steel.

Blade Height

Adjusting the height of the cutting blade is important for achieving clean and precise cuts. The blade height should be set just slightly above the material being cut. This allows for efficient cutting without excessive friction, reducing the risk of blade wear, overheating, or binding.

Material Type:

- a) Ferrous Metal: Steel gratings are typically made of ferrous metals like carbon steel or stainless steel. When cutting ferrous metals, it’s important to consider the hardness and thickness of the material. Using a blade specifically designed for cutting steel will provide better results compared to blades meant for softer materials like wood or plastic.

- b) Non-Ferrous Metal: Non-ferrous metals such as aluminum or copper can also be used for grating. These metals are generally softer and require different cutting techniques and blades. Consult the blade manufacturer’s recommendations for cutting non-ferrous metals to ensure optimal performance.

Speed

Finding the right cutting speed is crucial for efficient and accurate cuts. Cutting too slowly can cause excessive friction, leading to blade wear, overheating, and potential damage to the material.

Cutting too fast, on the other hand, may result in rough edges or an increased risk of kickback. Follow the manufacturer’s guidelines for the recommended cutting speed based on the blade type and material being cut.

The Kickback

Kickback refers to the sudden and violent backward movement of the cutting tool during operation, which can be dangerous. To avoid kickback when cutting steel gratings, ensure a firm grip on the cutting tool, maintain proper control, and keep the workpiece secure.

Avoid binding the blade, especially when cutting thick or dense materials. Additionally, using a blade guard and following safe cutting techniques can minimize the risk of kickback.

3. Steps of cleaning wire mesh

Step 1. Mark the Grating for Cutting

- Measure and mark the desired cutting lines on the steel grating using a measuring tape, square, and a marker or scribe.

- Ensure that your markings are precise and aligned with the intended dimensions to achieve accurate cuts.

Step 2. Make the Adjustments

- Adjust the blade height: Set the cutting blade to the appropriate height just above the steel grating. Follow the manufacturer’s guidelines for the recommended blade height for cutting steel.

- Position the grating securely: Place the steel grating on a stable work surface, such as a sawhorse or workbench. Ensure it is firmly secured to prevent movement or vibrations during cutting.

Step 3. Turn on the Saw and Cut

- Ensure you are wearing the necessary safety equipment, including safety glasses and gloves.

- Power on the saw and allow it to reach its full speed before initiating the cut.

- Hold the saw firmly with both hands and position the blade on the marked cutting line.

- Apply gentle and consistent pressure as you guide the saw along the cutting line, allowing the blade to do the work.

- Maintain control of the saw throughout the cutting process, ensuring steady and smooth movements.

Step 4. Check for Rough Edges

- After completing the cut, inspect the edges of the steel grating for any rough or jagged areas.

- Use a file or grinder with a sanding disc to smooth out any rough edges or burrs. Hold the tool at a slight angle and apply gentle pressure while moving it along the edges in a controlled manner.

- Alternatively, use sandpaper or a deburring tool to remove any sharp edges and make the cut edges safe.

Step 5. Clean Up the Work Area

- Turn off the saw and safely set it aside.

- Clear the work area of any debris, metal shavings, or cut-off pieces.

- Dispose of the waste material appropriately, ensuring it does not pose a safety hazard.

- Store your cutting tools and equipment in their designated places.

Conclusion

By understanding the limitations of table saws and exploring alternative cutting methods, you can make informed decisions and ensure the best results when working with steel gratings. Discover the right tools and techniques to handle this task effectively and safely, ensuring a successful cutting experience.