Introduction

Steel grating products are beneficial for projects due to their strength, durability, and customization options. Depending on your needs, you may require steel gratings with specific sizes, shapes, or materials. Fortunately, many manufacturers offer customizable steel grating products that can meet any specifications.

In this article, we’ll explain the process of customizing steel grating products and explore their benefits.

1. What are product customization and its benefit?

Customizing steel gratings involves designing gratings to meet specific user needs. This ensures that the construction, design, and material of carbon steel grating are appropriate for the intended application. Customization provides more options in terms of size, shape, pattern, and style than standard off-the-shelf products.

It also helps reduce costs by eliminating unnecessary elements or components, since only what’s needed is included in the design. End-users can enjoy numerous benefits by customizing steel gratings, including improved efficiency and safety in their work environment.

- For example, customized gratings can provide better traction on stair treads or in areas subject to frequent foot traffic or slippery surfaces.

- By choosing a particular opening size and bar spacing pattern, customers can also reduce the chances of small items like kick plates, checker plates, tools, and equipment becoming trapped or lost in the grating.

- Additionally, custom gratings can be designed to withstand greater loads or temperatures than standard products, making them ideal for industrial applications.

2. The Process of Customizing Steel Grating Products

1. Determine the size, shape, and type of target gratings

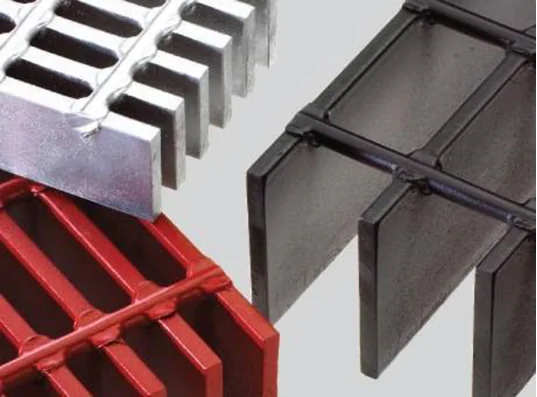

When selecting steel gratings, consider options like resistance welded, press-locked, and swaged types. Choose the one suitable for your project based on its application. Additionally, decide whether a standard or custom size is needed, considering specifications such as bearing bar centers, crossbar spacing, and length/width measurements

2. Choose the material

Steel gratings are manufactured using different grades of steel, each with varying mechanical properties like tensile strength, yield strength, and elongation values. Select a material grade based on the intended use of your steel grating product, ensuring it provides adequate corrosion resistance and strength.

3. Select the surface treatment

To enhance the lifespan and appearance of steel grating products, a protective coating is applied. This coating offers benefits such as corrosion resistance, aesthetic appeal, and slip resistance.

4. Pick the appropriate fasteners

When securing steel grating stock panels, it is crucial to choose suitable fasteners that prevent movement during operation or transportation. Consider marine-grade stainless steel fasteners, taking into account factors such as application conditions (e.g., wind velocity, temperature) and exposure to environmental elements like rain, snow, and saltwater.

5. Calculate loading capacity

It needs to consider factors such as size, shape, type, and material grade. This assessment ensures the grating can bear the expected load without deformation or breakage.

By possessing the necessary knowledge and making careful selections, customizing steel grating products for your project becomes easily achievable.

6. Place an Order

Once you have completed and understood all these steps, it’s time to order your custom-made steel grating product from a trusted supplier or manufacturer that can meet your specific requirements. These suppliers have professionals who possess extensive experience in producing high-quality and durable products that adhere to safety standards and regulations.

They can provide valuable advice on selecting the best material grade, type of grating, and surface treatments suitable for your needs. Additionally, they should be able to supply you with appropriate fasteners specifically designed for your grating product’s intended application.

Working with a reputable manufacturer or supplier ensures the assurance of quality, so it’s essential to conduct thorough research before placing an order for any custom-made steel gratings.

3. How to Measure Steel Grating Dimensions

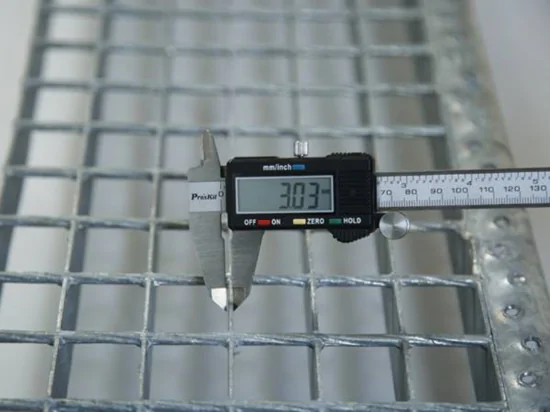

When measuring the dimensions of steel grating, it’s crucial to consider the size of the bearing bar and its spacing from the cross bars. The bearing bars are the load-bearing elements running parallel to each other, while the cross bars are welded or pressed locked perpendicular to them.

For rectangular mesh grating, measure both the length and width of the opening. In the case of square mesh grating, measure the dimension of one side of the opening.

In addition, it’s important to measure the thickness of both the bearing bars and cross bars. By combining all these components, you can calculate the overall size of the steel grating. And also make sure to carefully read the instructions provided before taking your measurements.

4. Suitable Types of Steel Gratings for various Applications

Steel grating is a versatile material utilized in various industrial and commercial applications, catering to different environments to ensure safety and durability.

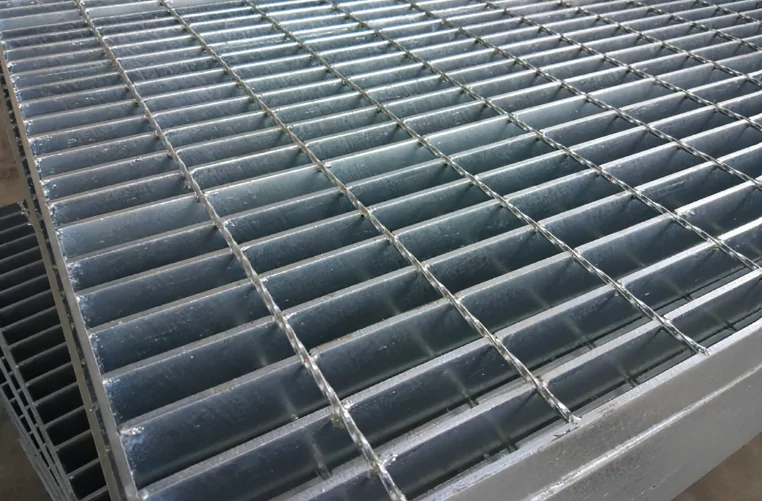

For outdoor settings, stainless steel gratings and galvanized gratings are commonly employed due to their resistance to corrosion and extreme weather conditions. These gratings offer effective drainage capabilities and excellent slip resistance.

In areas prone to moisture like swimming pools and bathroom floors, galvanized or electro-galvanized steel grates are preferred for their exceptional corrosion protection against water splashing or flooding. The open design of these fabricated gratings allows efficient liquid drainage while ensuring the safety of workers with their slip-resistant properties.

Aluminum is another popular choice for steel grating in commercial and industrial applications. Its lightweight nature and high strength make it ideal for various projects, including pedestrian walkways, decks, ramps, and catwalks. In addition to being corrosion-resistant and requiring low maintenance, aluminum gratings provide reliable slip resistance and are available in a range of colors to match the surrounding environment.

Regardless of the application or environment, it’s crucial to select the appropriate type of steel grating to ensure a safe and long-lasting installation. Seek guidance from experienced professionals who can advise on the best-suited grating type for optimal performance based on your specific needs.

FAQs About Customization

| What are the factors to be considered in customizing steel gratings? | Steel grating customization can be tailored to meet any specific requirements. Steel grates can be customized for shape, size, pattern, and more. |

| What is edge banding? | Edge banding is a popular option and involves welding a small bar around the perimeter of the steel piece to strengthen its edges and add protection against sharp corners or edges. |

| What does powder coating do? | Powder coating adds a layer of corrosion protection while also allowing you to choose from a variety of colors to suit your aesthetic needs. |

| What is hot dip galvanizing? | Hot dip galvanizing is a process commonly used to prevent corrosion and rusting. It involves immersing the original steel plate in molten zinc, which hardens as it cools, forming a durable protective layer. |

Conclusion

Steel bar grating products offer a versatile and cost-effective solution for many applications as they can be customized to suit the specific needs of your project. This customization ability allows for seamless integration into any type of grating project or space, ensuring superior strength and reliable performance even in heavy-duty scenarios.

By customizing these products, you gain the flexibility to design an extensive system that perfectly aligns with your unique requirements.