Introduction

Stainless steel gratings are a popular choice for many industrial applications. They offer superior corrosion resistance, high strength and durability, and low maintenance costs compared to other materials. Their open design also allows light, air, and liquids to pass through freely.

With so many advantages, it’s no wonder stainless steel gratings are an essential part of many industrial operations. Whether you need grating for a walkway, platform, or other application, stainless steel is a perfect choice.

The 5 common types of stainless steel gratings are:

- Welded stainless steel grating

- Press-locked stainless steel grating

- Swage-locked stainless steel grating

- 304 stainless steel grating

- 305 stainless steel grating

We will discuss each of these types of stainless steel gratings and identify how they are made, their applications, and their advantages.

What is stainless steel grating?

Stainless steel gratings are made from high-grade stainless steel, providing superior durability and strength when compared to traditional materials like wood or plastic. Gratings can be used for a variety of purposes, such as flooring, fencing, stair treads, and structural supports.

Stainless steel grating is strong enough to withstand heavy foot traffic and weather-resistant enough to resist corrosion in outdoor applications. It is also easy to clean and maintain. With its wide range of applications, stainless steel grating has become a popular choice for many businesses and homeowners alike.

The versatile material can be customized with different styles, sizes, and finishes to fit any project’s needs.

5 Common types of stainless steel grating

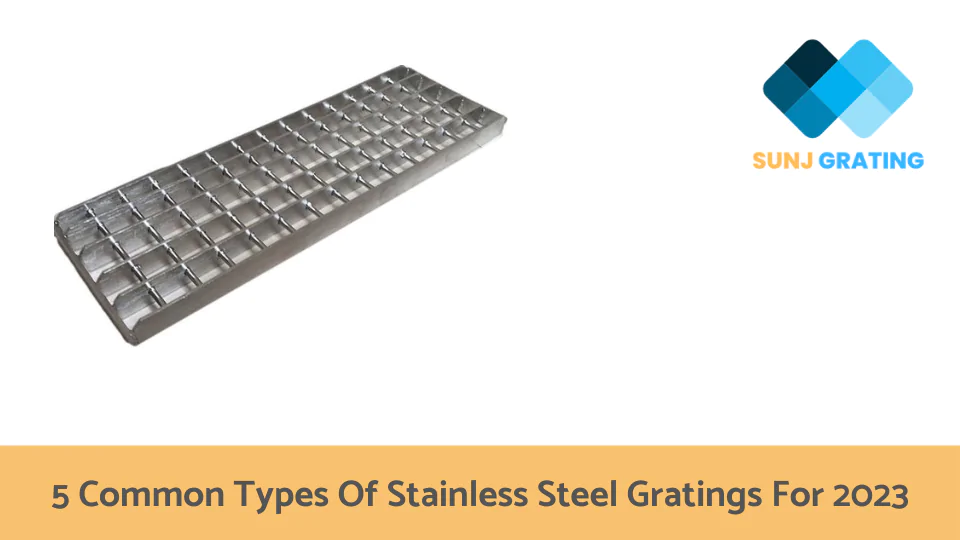

Welded stainless steel grating

Welded stainless steel grating is a metal grid consisting of parallel and perpendicular bearing bars, cross rods, and fasteners. It is manufactured by cutting and welding to form the desired shape. The bearing bars are connected with cross rods which add strength and rigidity to the structure.

This type of grating is strong, resistant to corrosion, and can be used in both interior and exterior applications. With its strength, durability, and stylish appearance, welded stainless steel grating has become increasingly popular for use in many areas including architectural designs, walkways, staircases, mezzanines, catwalks, bridges, and more.

Additionally, it can be painted or anodized for added customizability.

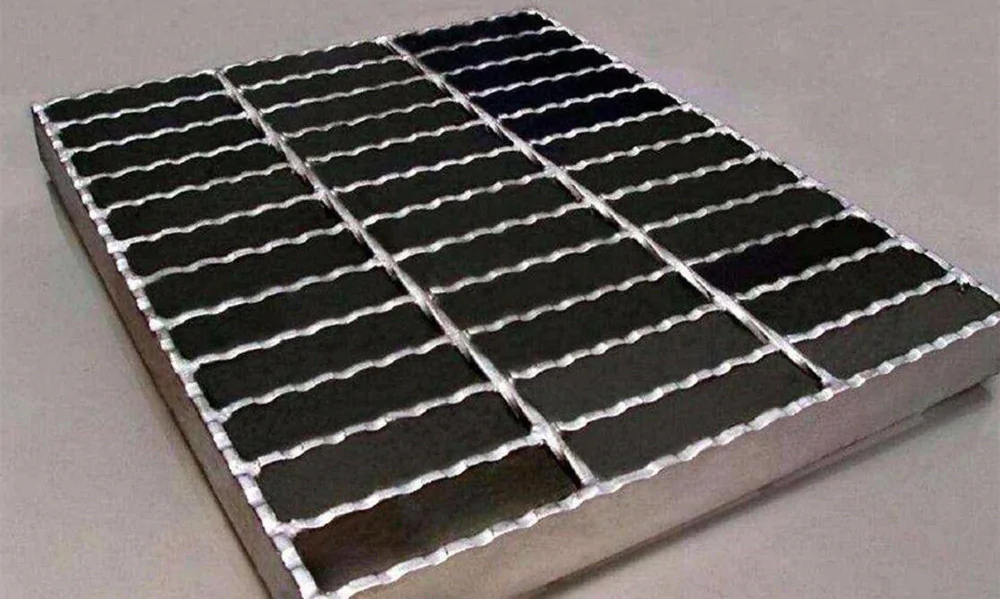

Press-locked stainless steel grating

Press-locked stainless steel grating is a sturdy, low-maintenance solution for industrial areas that require superior corrosion resistance. It is constructed by pressing one bearing bar into another at high pressure to create a secure interlock.

The resulting grating has greater strength and rigidity than standard welded or riveted gratings, which makes it ideal for applications that require extra durability. Moreover, its smooth surface allows debris and fluids to flow freely between the bearing bars, reducing maintenance time and effort in keeping the surfaces clean.

With press-locked stainless steel grating being so easy to install and maintain, it’s no wonder why this type of grating is growing in popularity among businesses looking for reliable infrastructure solutions.

Swage-locked stainless steel grating

Swage-locked stainless steel grating is a type of metal mesh that offers superior resistance to corrosion, wear, tear, and other types of damage. The swaging process locks individual grating components together at the intersections to form a single, rigid pane that provides optimal strength while allowing for flexibility in the system design.

Swage-locked grating also helps reduce maintenance costs due to its durability and ease of cleaning. It can be used in many applications such as stairways, walkways, platforms, ramps, and more. Its unique construction allows it to stand up to high-traffic areas with minimal wear over time.

In addition, it is cost-effective because it requires less material than traditional welded or riveted bar grating systems.

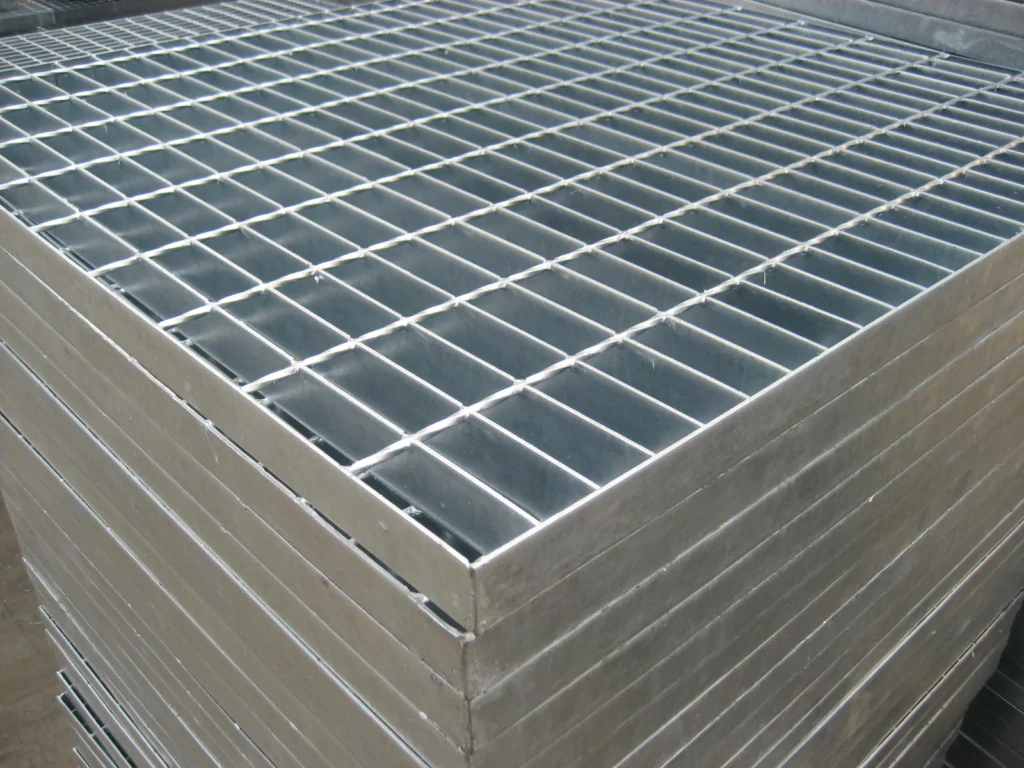

304 stainless steel grating

304 stainless steel grating is a type of metal grating that is highly corrosion-resistant and has excellent strength and durability. This material is often used in environments where corrosive materials are present, such as food processing areas or near coastal regions, due to its robust nature.

304 stainless steel grating can also be utilized for commercial applications, offering a durable solution for many public and private installations. The open mesh design of the grate allows for easy air and liquid flow, making it ideal for use in drainage systems or walkways.

Additionally, its non-porous surface makes 304 stainless steel grating an ideal choice for outdoor settings where slippery surfaces may be a safety hazard.

305 stainless steel grating

305 stainless steel grating is a type of corrosion-resistant metal grating that is particularly well-suited for use in corrosive environments.

This material has a higher resistance to pitting and crevice corrosion compared with other types of stainless steel, making it an ideal choice for high moisture or saline environments such as marine structures. The 305 alloy grade also offers good formability and weldability, which makes it easy to fabricate into various shapes and sizes.

Additionally, its excellent finish helps protect the surface from dirt and debris buildup. In many applications, 305 stainless steel grating provides superior durability and longevity over traditional materials while maintaining a clean aesthetic appearance.

The advantages of stainless steel grating

Stainless steel grating is highly resistant to corrosion, making it an ideal choice for outdoor or maritime applications. Additionally, stainless steel is non-magnetic and can withstand high temperatures, making it suitable for use in industrial settings as well.

Its durability and low maintenance requirements make stainless steel grating a reliable long-term investment. Furthermore, stainless steel grating provides excellent surface slip resistance that helps prevent slips and falls in wet or greasy areas.

Finally, its attractive appearance enhances the aesthetics of any space while providing a durable solution. Stainless steel grating is truly an all-purpose grating material that offers several advantages over other materials including aluminum and plastic.

Conclusion

Overall, stainless steel grating is an ideal material for a variety of applications due to its strength, durability, and corrosion resistance. Its wide range of uses makes it suitable for both indoor and outdoor environments, and its attractive aesthetic value adds a touch of sophistication to any space.

It is easy to install, requires minimal maintenance, and can be customized according to the specific requirements of each installation.

In addition, stainless steel grating has many advantages over other materials such as cost-effectiveness, ease of use, long-term performance, and environmental friendliness. With all these benefits in mind, it is no surprise that stainless steel grating has become one of the most popular choices for industrial flooring solutions around the world.