Have you ever been overwhelmed with the myriad of choices when selecting steel grating for a project? It’s a common issue. Selecting the wrong type can lead to unnecessary expenses, safety hazards, and premature wear and tear. Ensuring the right choice is essential.

Steel grating plays a crucial role in numerous construction and architectural projects. Different applications require specific types of grating for optimal performance and longevity. By understanding the types of steel grating available and the considerations for each, you’re on your way to making an informed decision. With this knowledge in hand, your project will not only meet its functional requirements but will also stand the test of time. Let’s delve deeper and ensure your next project is a success!

Types of Steel Grating

Bar Grating

Bar grating is one of the most common types of steel grating, recognized for its series of parallel bars held together by perpendicular crossbars. This design ensures a sturdy structure and allows for various spacing between the bars to suit different requirements.

| Uses | Widely used in industrial settings, it’s perfect for platforms, walkways, and drainage systems. |

| Benefits | Its open design ensures excellent ventilation and drainage, while its solid construction can support heavy loads. |

Expanded Metal Grating

This grating type is produced by slitting and stretching metal sheets to create a diamond-shaped pattern. This results in a grating with a mesh-like appearance.

| Uses | Ideally suited for ramps, walkways, and certain architectural designs where an aesthetic appeal is desired without compromising on strength. |

| Benefits | It provides a slip-resistant surface, is durable, and offers a lighter weight option compared to bar grating. |

Safety Grating

Safety grating prioritizes the prevention of slips, trips, and falls. Its design consists of serrated surfaces and perforated holes.

| Uses | Primarily for stair treads, walkways, platforms, and other areas where safety is a concern. |

| Benefits | The high friction surface minimizes the risk of accidents, especially in environments prone to liquids or debris. |

Heavy Duty Grating

Constructed for areas with high traffic or heavy loads, this grating type has larger bars and cross rods.

| Uses | Airports, highways, industrial plants, and any area expecting heavy loads or high foot traffic. |

| Benefits | Built for endurance, it’s designed to withstand extreme pressures and weights. |

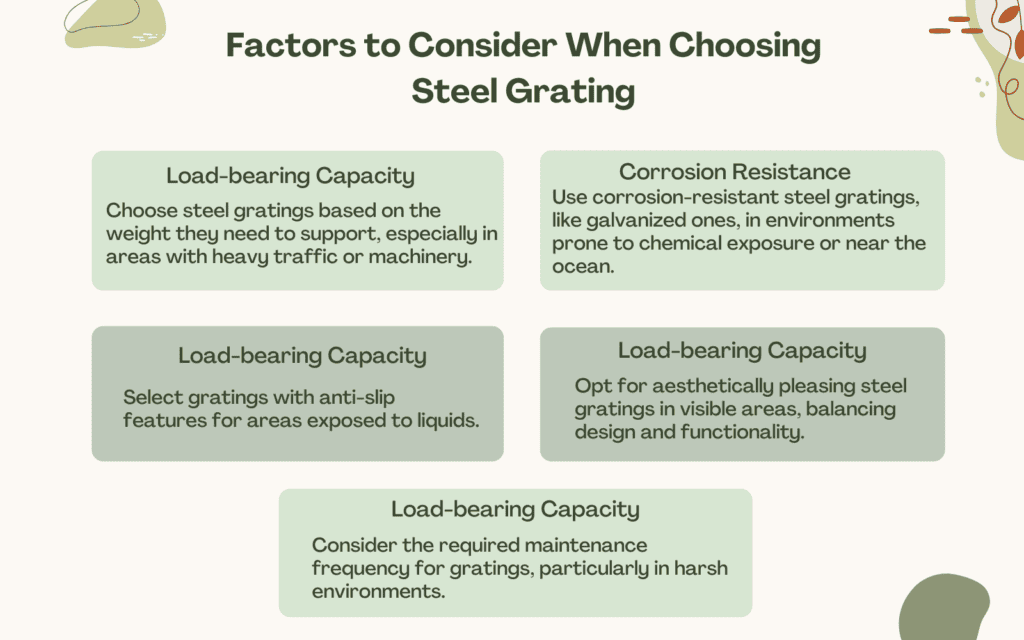

Factors to Consider When Choosing Steel Grating

Load-bearing Capacity

Before settling on a steel grating type, it’s essential to evaluate the weight it will be expected to support. Not all gratings are created equal, and some are more suited to heavier weights. For areas with heavy machinery or high foot traffic, a robust grating like the heavy-duty type is indispensable.

Corrosion Resistance

Environmental factors can affect the longevity of steel grating. For projects near the ocean or those exposed to chemicals, corrosion-resistant finishes or treatments, like galvanizing, become vital. This ensures the grating’s durability and longevity, even in harsh conditions.

Slip Resistance

Safety is paramount. Gratings in areas exposed to rain, oil, or other liquids should have surfaces designed to prevent slipping. Textures, serrations, or perforations can enhance slip resistance, making it safer for users.

Aesthetic Appeal

For architectural projects or areas visible to the public, aesthetics play a crucial role. While functionality is important, the design, finish, and appearance can complement the overall look of a space. It’s important to strike a balance between functionality and design.

Maintenance Requirements

All gratings require some level of maintenance, but some need more frequent checks and cleaning. Consider the environment and usage to determine how often maintenance is required. For instance, a grating exposed to harsh chemicals might need regular checks for signs of wear or damage.

Applications and Suitability

| Industrial Applications | Strength and durability are the main focus. |

| Architectural Projects | Blend aesthetics with strength, often featuring custom designs. |

| Public Infrastructure | Safety and accessibility are priorities, it also requires slip-resistance and disability-friendly designs. |

| Residential Uses | Combine good looks with functionality for areas like decks and balconies. |

Industrial Applications

In the industrial sector, steel gratings bear the brunt of heavy machinery, constant movement, and challenging environmental conditions. Here, strength and durability are of the utmost importance. Heavy-duty gratings, with their robust construction, are the preferred choice, ensuring longevity even in the harshest of conditions.

Architectural Projects

When it comes to architectural endeavors, it’s not just about strength; aesthetics play an equally crucial role. Gratings in these settings should complement the overall design, often necessitating custom finishes or unique patterns. Expanded metal grating, with its mesh-like appearance, can add a touch of elegance without compromising on strength.

Public Infrastructure

Public areas such as train stations, parks, or bridges have a unique set of requirements. Safety is paramount, but so is accessibility. Gratings here need to be slip-resistant and durable but also accommodate the needs of all citizens, including those with disabilities. The design should allow for easy movement and be free from potential hazards.

Residential Uses

For homes and residential areas, the grating serves dual purposes: aesthetic appeal and functionality. Whether it’s for a deck, balcony, or garden walkway, homeowners want something that looks good and serves its purpose efficiently. A balance between design and utility is essential here.

Safety Precautions

Installation

A poorly installed grating can lead to a host of issues, from uneven walking surfaces to potential collapse. Ensuring a proper fit and securing the grating correctly are paramount to prevent mishaps. Using the right fixtures, checking alignments, and regular inspections immediately after installation can avert many potential problems.

Maintenance

While steel gratings are designed for durability, periodic maintenance is essential. Regular checks can identify areas of wear or potential weaknesses before they become significant problems. Cleaning, checking for corrosion, and ensuring that the grating remains securely in place are all part of essential upkeep.

Conclusion

Selecting the right steel grating is more than just a choice; it’s a commitment to safety, longevity, and aesthetics. With the myriad of options available, understanding the specifics of each type and their suitability for different applications becomes vital.

Always remember, the foundation of a successful project lies in making informed decisions. If ever in doubt, consult with professionals or manufacturers who can provide insights tailored to your project’s unique needs. Your project’s success lies in the details. Choose wisely.