Have you ever walked on a steel grating and wondered how it supports so much weight? The intricate design and the strength of steel might seem like simple components, but there’s a deep science behind it. Many industries rely on steel grating for its durability and load-bearing capacity, but few understand the intricate details that make it so reliable.

Steel grating, with its interwoven pattern and robust material, is designed to bear significant loads. Its unique construction ensures that weight is distributed evenly across its surface, preventing any single point from bearing too much stress. This distribution is the key to its impressive load-bearing capacity.

Understanding this science not only satisfies our curiosity but also emphasizes the importance of choosing the right grating for specific applications. Dive in with us as we unravel the fascinating science behind steel grating’s load-bearing prowess.

Basics of Steel as a Material

Properties of Steel

Tensile Strength

Tensile strength is the resistance of a material to breaking under tension. It’s quantified by the maximum amount of tensile stress a material can withstand without failure. For steel grating, high tensile strength ensures that the grating can support heavy loads without breaking or deforming. This is especially crucial in industrial settings where heavy machinery or equipment might be used.

Ductility

Ductility refers to a material’s ability to deform and stretch under tension without breaking. A highly ductile material can be drawn into thin wires or bent without snapping. Ductility in steel grating allows it to flex slightly under load, accommodating weight and reducing the risk of breakage. This property is especially vital in areas with high foot traffic or dynamic loads.

Hardness

Hardness measures a material’s resistance to deformation, especially surface deformation like scratching or denting. In steel grating, hardness ensures that the surface can withstand the wear and tear of constant use without showing signs of damage. This contributes to the grating’s longevity and reduces maintenance needs.

How Alloying Elements Influence Steel’s Strength

Different alloying elements can significantly modify steel’s properties

| Carbon | By adjusting the carbon content, manufacturers can control steel’s hardness and strength. A higher carbon content can make the grating more resistant to wear, but it might also make it less ductile. |

| Manganese | Manganese helps in the hardening process and also improves the steel’s hot-working properties. It also enhances the grating’s overall strength and resistance to impact. |

| Other Elements | Chromium increases wear resistance and toughness. Nickel adds strength and toughness. Molybdenum increases strength and resistance to corrosion. |

The Design of Steel Grating

Bar Grating

Comprises a series of metal bars positioned vertically and horizontally to form a grid-like pattern. Offers an excellent strength-to-weight ratio, making it suitable for heavy-duty applications. The open design also allows for easy drainage and airflow.

Diamond Grating

Features a diamond-shaped pattern, often formed by pressing a single piece of metal. The diamond pattern provides enhanced slip resistance, making it ideal for wet or oily environments.

Plank Grating

Consists of a series of flat metal planks, often with perforations for drainage. Offers a more uniform surface, suitable for pedestrian areas. The solid surface can also support smaller objects that might fall through more open designs.

Load Distribution on Steel Grating

Static vs. Dynamic Loads

| Type of Load | Description | Example | Implications for Steel Grating |

| Static Load | A constant force applied to a structure. | A stationary machine’s weight on grating. | Steel grating must be robust enough to support these constant weights without deforming over time. |

| Dynamic Load | A varying force, often sudden or changing. | People walking or vehicles moving over grating. | Grating must be resilient and flexible to accommodate these changing forces, ensuring safety and longevity. |

Dynamic loads, in particular, can be more challenging for steel grating as they introduce stresses that can change rapidly. This can lead to wear and tear over time, emphasizing the need for high-quality materials and construction in grating design.

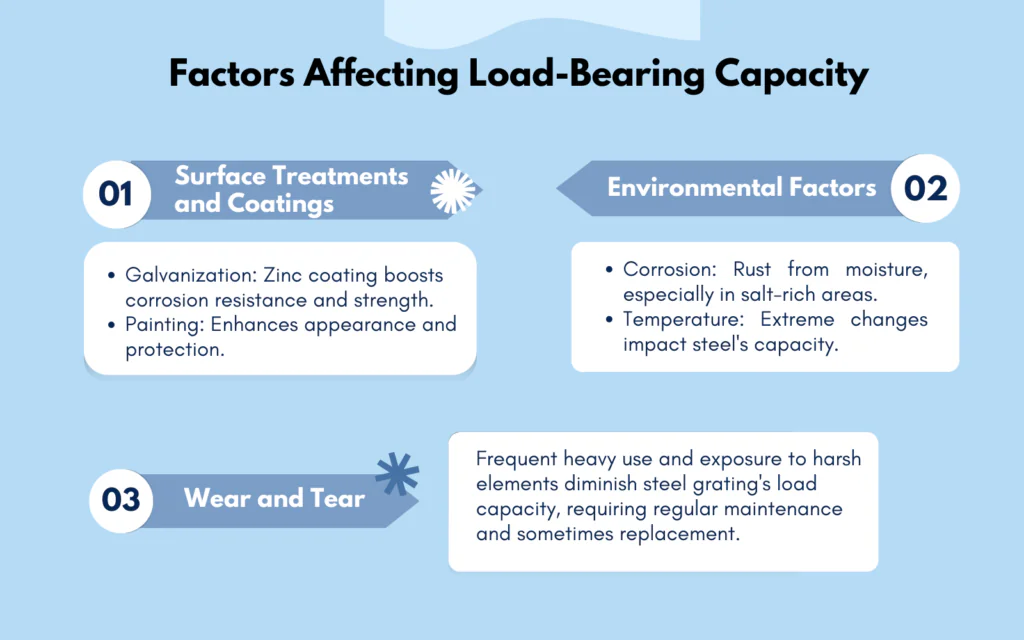

Factors Affecting Load-Bearing Capacity

Testing and Standards

Common Tests

Several tests are employed to determine the load-bearing capacity of steel grating:

- Load Tests: These directly measure the maximum weight the grating can support without deforming.

- Bend Tests: Used to determine the grating’s flexibility and resistance to breaking under bending forces.

International Standards and Benchmarks

Various international organizations set standards for steel grating’s load-bearing capacity, ensuring safety and reliability. Adhering to these standards is crucial, especially in critical applications like industrial platforms or pedestrian bridges.

Regular Inspections and Maintenance

To ensure the longevity and safety of steel grating installations, regular inspections are vital. These can identify signs of wear, corrosion, or damage, allowing for timely repairs or replacements.

Practical Implications

| Safety First | Understanding the load-bearing capacity of steel grating is not just a technical concern—it’s a matter of safety. Overloading or using damaged grating can lead to catastrophic failures, endangering lives. |

| Real-world Failures | There have been instances where steel grating installations failed due to overloading or lack of maintenance. These real-world examples underscore the importance of adhering to standards and regular inspections. |

| Ensuring Longevity and Safety | Choose the right type of grating for the specific application. Adhere to load-bearing guidelines. Conduct regular maintenance and inspections. |

Conclusion

Steel grating, with its intricate design and robust material composition, is a marvel of engineering. Its ability to support significant loads is not just a result of steel’s inherent properties but also the culmination of careful design, quality manufacturing, and appropriate maintenance. By understanding the science behind its load-bearing capacity and adhering to best practices, we can ensure the safety, longevity, and efficiency of steel grating installations across various applications.