Have you ever considered the dire consequences a fire can have in an industrial setting? Fires, aside from endangering lives, can lead to colossal financial losses, damage expensive machinery, and tarnish reputations. Ensuring robust fire safety is not just a regulatory necessity but a moral obligation.

Flame-resistant steel grating emerges as a linchpin in this endeavor. This specialized grating is engineered to withstand and mitigate the spread of flames, providing not only a protective barrier for infrastructure and equipment but also ensuring safe passage during emergencies. Understanding and implementing such safeguards is pivotal to maintaining a secure environment. Dive into this article to grasp why it’s paramount for every industry to integrate flame-resistant steel grating into their safety protocols.

What is Steel Grating?

Definition and Primary Uses

Steel grating is a framework of parallel and perpendicular bars, usually made of steel, used to cover open areas in flooring, walkways, and platforms. These gratings serve multiple purposes: they provide traction for foot traffic, allow for the passage of light and air, and keep debris from falling through while supporting the weight of both people and equipment. Predominantly used in industrial areas, steel grating is essential for catwalks, drain covers, stair treads, and various other applications.

Common Materials Used in Steel Grating Production

While the term “steel grating” might suggest a singular material, it encompasses a range of alloys and treatments to meet specific needs. The most commonly used materials include:

- Carbon Steel: Renowned for its strength and durability, it’s the most frequently used material for grating.

- Stainless Steel: Preferred for its resistance to corrosion, stainless steel gratings are often utilized in environments exposed to chemicals or high moisture.

- Galvanized Steel: Carbon steel treated with a protective zinc coating to prevent rusting, making it ideal for outdoor applications.

Understanding Flame Resistance

Definition of Flame-Resistant Materials

Flame-resistant materials are specifically designed to resist ignition and limit the spread of flames when exposed to fire or high temperatures. Unlike flammable materials that easily catch fire, flame-resistant materials have undergone special treatments or are made of inherently resistant fibers to provide a heightened level of protection.

How Flame Resistance is Measured

To determine a material’s flame resistance, standardized tests are performed, assessing various criteria such as:

- Ignition Time: How long it takes for a material to ignite when exposed to a flame.

- Flame Spread: The rate at which fire moves across the surface of the material.

- Heat Release: The amount of heat energy released by the material during combustion.

- Smoke Production: The volume of smoke a material produces when burning.

Various international standards, like the ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization), have specific tests and benchmarks to determine the flame resistance of materials. Industries must be aware of these measurements and ensure the materials they utilize meet or exceed the required standards.

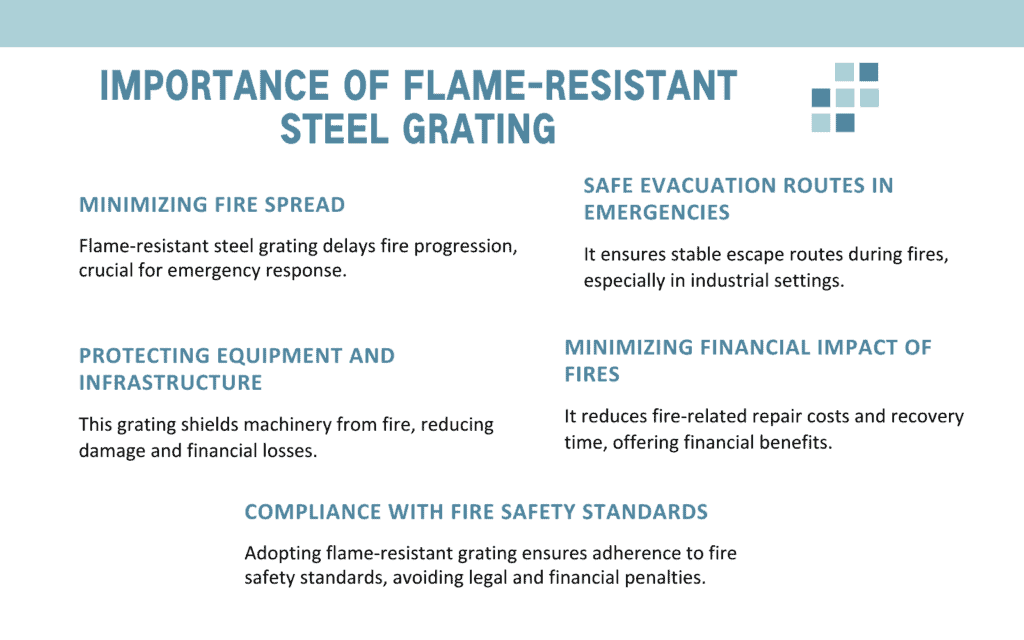

Importance of Flame-Resistant Steel Grating

Safety First: Minimizing the Spread of Fire

The primary purpose of flame-resistant steel grating is to limit the rapid spread of fire. When flames come into contact with standard materials, they often act as fuel, allowing the fire to move quickly across surfaces. Flame-resistant steel grating, on the other hand, is designed to resist ignition, thereby slowing down the fire’s progression. This delay can be crucial in allowing emergency responders enough time to control and extinguish the flames.

Providing Safe Evacuation Routes in Emergency Scenarios

In case of a fire, having a reliable evacuation route is paramount to saving lives. Flame-resistant steel grating ensures that pathways, walkways, and exits remain intact and do not collapse under the intense heat, allowing individuals to evacuate safely. These gratings can withstand high temperatures, ensuring a safer escape route, especially in industrial environments where traditional exits might be compromised.

Protection of Equipment & Infrastructure

Reducing Damage to Machinery and Structures

Industrial settings often house expensive and vital machinery. A fire can cause irreversible damage to these machines, leading to both operational and financial setbacks. Flame-resistant steel grating acts as a protective layer, reducing the direct impact of flames on the equipment below. By acting as a barrier, it can prevent or at least minimize damage to the infrastructure and equipment.

Minimizing the Financial Impacts of Fires

The aftermath of a fire is not just about the immediate damages. There are long-term financial implications like repairs, replacements, and downtime in operations. Flame-resistant steel grating can significantly reduce the extent of damage, leading to lower repair costs and quicker recovery times. The investment in flame-resistant grating can be seen as a preventive measure against potential massive financial losses.

Compliance with Regulations & Standards

Meeting Local and International Fire Safety Standards

Many regions and countries have established stringent fire safety standards for industrial and commercial settings. These standards often mandate the use of flame-resistant materials, including steel grating, in specific applications. By incorporating flame-resistant steel grating, businesses ensure that they are in full compliance with these standards, demonstrating their commitment to safety.

Avoiding Penalties and Legal Consequences

Non-compliance with fire safety regulations can lead to hefty fines and even legal actions. Businesses found neglecting these regulations might face shutdowns, lawsuits, or other severe consequences. Employing flame-resistant steel grating helps companies avoid these pitfalls, ensuring they meet all safety requirements and protect their reputation in the process.

Flame-Resistant Steel Grating vs. Traditional Steel Grating

| Property/Feature | Traditional Steel Grating | Flame-Resistant Steel Grating |

| Ignition Resistance | Moderate | High |

| Flame Spread | Can spread flames with intensity | Limits flame spread |

| Heat Tolerance | Standard tolerance | Enhanced high-temperature resistance |

| Durability in Fire Conditions | Can deform under intense heat | Maintains structural integrity |

| Cost | Generally less expensive | Higher due to special treatments |

| Compliance with Fire Safety Standards | Might not meet all standards | Typically meets/exceeds standards |

Additional Benefits of Flame-Resistant Varieties

Flame-resistant steel grating not only offers the foundational benefits of traditional steel grating but also brings enhanced fire safety, compliance with stringent fire safety standards, longer lifespan under fire conditions, and potential insurance benefits due to reduced fire risks.

Real-World Applications & Case Studies

Instances where flame-resistant steel grating prevented major disasters:

In a recent chemical plant fire in Europe, flame-resistant steel grating played a pivotal role. When a blaze broke out in one section of the plant, the grating prevented the fire’s rapid spread, allowing emergency responders to contain it effectively.

Benefits observed by industries that have adopted this material:

Many industrial sectors, from petrochemical to manufacturing, have noted a marked reduction in fire-related incidents and damages after adopting flame-resistant steel grating. Additionally, companies have reported savings in insurance premiums and improved compliance ratings.

Choosing the Right Flame-Resistant Steel Grating

Factors to Consider

| Material | Depending on the environment, choose between carbon steel, stainless steel, or galvanized steel with flame-resistant properties. |

| Design | The pattern and mesh size can influence the grating’s performance. |

| Size | Ensure the grating fits the intended area perfectly. |

| Coating | Additional coatings might enhance flame resistance and longevity. |

Importance of Third-Party Certifications

Always opt for gratings that come with certifications from recognized testing organizations. These certifications validate the grating’s flame-resistant properties, ensuring that they meet the claimed standards.

Conclusion

The world of industrial safety has seen significant advancements, and flame-resistant steel grating stands out as a prime example. This specialized material not only ensures the safety of personnel during fire emergencies but also protects valuable infrastructure.

As industries continue to evolve and expand, integrating such paramount safety measures becomes not just a regulatory need but a moral and financial imperative. It’s high time industries prioritize and invest in flame-resistant steel grating to safeguard their future.