Introduction

Steel grating has become a staple in the construction and manufacturing sectors due to its robustness, versatility, and high load-bearing capacity. However, to withstand harsh environments and prolong its lifespan, steel grating often requires a protective coating.

Two popular options are hot-dipped galvanizing and painting. This article will delve into the characteristics, pros, and cons of both hot-dipped galvanized and painted steel grating, offering a comprehensive comparison to help industry professionals make informed decisions.

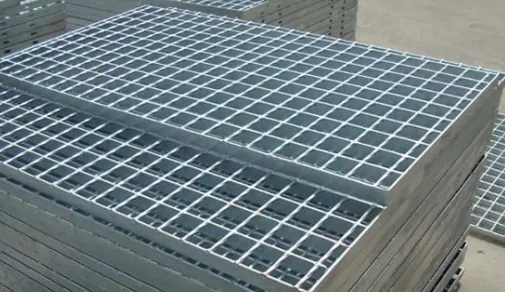

Understanding Hot-Dipped Galvanized Steel Grating

Description and Manufacturing Process

Hot-dipped galvanized steel grating refers to the process where steel grating is submerged in a bath of molten zinc. This procedure, known as galvanization, forms a metallurgical bond between the zinc and the underlying steel or iron, creating a robust, protective layer resistant to wear and corrosion.

The galvanized coating offers dual protection: it forms a physical barrier, preventing corrosive substances from reaching the steel, and offers cathodic protection where zinc, being more reactive than steel, corrodes first, thereby protecting the steel.

Pros and Cons

| ✅Pros | ❎Cons |

| Excellent longevity Durable Low maintenance Save cost in the long term | Initial cost is high Heavier than other gratings due to the zinc coating Zinc layer may get scratched or damaged |

The primary benefit of hot-dipped galvanized steel grating is its longevity. The zinc coating forms a protective barrier that prevents rust and other forms of corrosion, extending the life of the steel grating substantially. This means you’ll have to replace your steel grating far less frequently, saving time and money.

Hot-dipped galvanized steel grating is highly durable. The zinc coating provides an unmatched level of protection against wear and tear, keeping the steel grating in good condition for longer. This makes it an ideal choice for applications where durability is a crucial factor.

The low-maintenance nature of hot-dipped galvanized steel grating is yet another advantage. Once the galvanizing process is complete the steel requires little to no maintenance, thanks to the protective zinc coating. The galvanized coating can withstand harsh environmental conditions, reducing maintenance costs over time.

The initial cost of galvanized steel grating can be higher compared to other types of steel grating. However, this is often offset by the longer lifespan and lower maintenance costs. Also, it can be heavier than other types of grating due to the added weight of the zinc coating. This can make installation more challenging.

Finally, while the zinc coating is highly durable, it can still be scratched or damaged by extremely harsh conditions or rough handling, potentially exposing the steel underneath to the risk of corrosion.

Best Applications and Uses

Hot-dipped galvanized steel grating is highly valued across various applications due to its durability and resistance to corrosion. In industrial settings, including chemical plants and power generation facilities, it withstands heavy loads and corrosive conditions.

It’s also used extensively in public infrastructure projects like highways and bridges for drainage systems and pedestrian walkways. In marine environments, such as docks and shipyards, its resistance to saltwater is advantageous.

The agricultural sector uses it for livestock enclosures and walkways due to its strength and outdoor resilience. Lastly, architects often employ hot-dipped galvanized steel grating in design elements like fences and stairs for its rugged aesthetic and functionality.

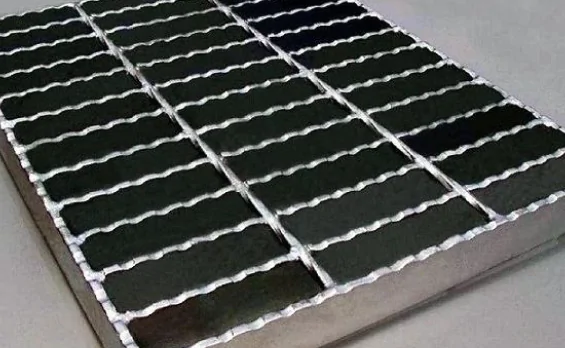

Understanding Painted Steel Grating

Description and Manufacturing Process

Painted steel grating involves applying a layer of paint to the steel surface as a protective coating. This paint often contains corrosion-inhibitors, pigments, and fillers, providing a degree of protection against the elements while allowing for aesthetic customization. The painting process typically involves preparation steps like cleaning and priming before the application of the paint itself.

The painting process for steel grating involves several crucial steps. Firstly, the steel grating is thoroughly cleaned and degreased. This is typically achieved through a mix of mechanical and chemical cleaning processes that remove surface impurities and prepare the metal for the subsequent coating.

After the grating is clean, a primer is applied to provide a base for the paint. This helps to ensure a strong bond between the paint and the metal, improving the durability and longevity of the finish. Following the primer, the actual paint is applied, commonly through spray painting, roller painting, or brush painting, which gives the grating its desired color and appearance. Lastly, a final clear coat may be added to protect the paint and enhance its shine.

Pros and Cons

| ✅Pros | ❎Cons |

| Aesthetic appeal Can be customized Cost-effective | Paint can fade, chip or peel Require periodic maintenance and repaints |

One of the key advantages of painted steel grating is its aesthetic appeal. Through painting, steel grating can be customized to fit a variety of color schemes and designs. This means it can blend seamlessly into the overall aesthetic of a space, or stand out as a contrasting feature, depending on your needs and preferences.

Another notable advantage of painted steel grating is its cost-effectiveness. Painting is a relatively inexpensive way to enhance the appearance and longevity of steel grating. By protecting the metal against corrosion and other forms of wear and tear, painting can extend its lifespan and reduce the need for costly repairs or replacements.

The paint on the grating can fade, chip or peel over time, particularly in harsh conditions or heavy traffic areas. This can detract from its aesthetic appeal and may require periodic touch-ups or repaints. Painted steel grating requires more frequent maintenance to keep the paint in good condition and ensure continuous protection.

Best Applications and Uses

Architects often favor it for building facades, fences, and decorative features, thanks to its color customization capabilities. Commercial facilities like shopping malls and parking garages use painted grating in stair treads, walkways, and floor grilles, where its appearance enhances the overall design.

In industrial environments, it’s used for catwalks, platforms, and safety barriers, where the paint provides some corrosion resistance. It’s also employed in public utilities such as drainage systems and bridge decking, blending with or contrasting the surroundings as needed. Thus, painted steel grating’s versatile nature allows it to serve various applications effectively.

Hot-Dipped Galvanized VS Painted: A Comparative Analysis

The choice between hot-dipped galvanized steel grating and painted steel grating holds significant importance in various industries. Both options offer unique features and benefits, including differences in durability, maintenance, cost, and aesthetic appeal. Let’s delve into a close comparison of these two.

Comparison of Durability and Lifespan

When it comes to durability and lifespan, hot-dipped galvanized grating has a distinct advantage. The zinc coating from galvanization forms a robust, protective layer that can withstand harsh environmental conditions, significantly enhancing the lifespan of the grating.

On the other hand, while paint does provide a layer of protection, it’s typically less durable. Paint may chip or crack over time, and its lifespan tends to be shorter, requiring regular maintenance and repainting.

Comparison of Corrosion Resistance

In terms of corrosion resistance, hot-dipped galvanized grating again stands out. The galvanized layer offers excellent protection against corrosive elements. Even if the coating is slightly damaged, the surrounding zinc will continue to offer cathodic protection to the exposed steel.

Paint can also provide a degree of corrosion resistance, particularly if corrosion-inhibiting additives are used. However, any damage to the paint layer—like chipping or cracking—can expose the underlying steel to corrosive elements, potentially leading to rust.

Comparison of Aesthetics and Finish

When aesthetics come into play, painted steel grating shines. The availability of a broad spectrum of colors makes it an attractive option for applications where visual appeal is important. Painted steel grating can be tailored to match any design requirements or blend seamlessly with its surroundings.

In contrast, hot-dipped galvanized grating, with its rugged, metallic finish, might not be as aesthetically pleasing for decorative applications. However, it is worth noting that its shiny, zinc-gray appearance can be suitable for industrial or rustic-themed designs.

Comparison of Cost and Maintenance

While hot-dipped galvanizing might have a higher upfront cost than painting, it often proves to be more cost-effective in the long run due to its durability and minimal maintenance requirements. Its prolonged lifespan can result in fewer replacement costs, making it an economical choice for long-term projects.

Painted steel grating, although cheaper initially, may incur higher maintenance costs over time. Regular inspections, touch-ups, and repainting are necessary to ensure its aesthetic appeal and protective capability, which could add up over the grating’s lifetime.

Comparison of Environmental Impact

In the context of environmental impact, both hot-dipped galvanized and painted steel grating have their considerations. The hot-dip galvanizing process produces fewer emissions and uses less energy compared to the manufacture of paint. Moreover, the long lifespan of galvanized steel reduces the frequency of replacement, resulting in lower resource use over time.

On the other hand, many paints contain volatile organic compounds (VOCs) that can contribute to air pollution. However, advances in paint technology have led to the development of low-VOC and VOC-free paints that are more environmentally friendly.

Factors to Consider When Choosing Between Hot-Dipped Galvanized and Painted Steel Grating

| 1 | The Environment and Exposure to Elements |

| 2 | Durability and Maintenance Requirements |

| 3 | Cost and Budget Constraints |

| 4 | Aesthetic Preferences |

The Environment and Exposure to Elements

Consider the environment in which the grating will be used. For harsh environments or those with high exposure to corrosive elements, hot-dipped galvanized grating may be the best choice. For indoor applications or areas with less exposure, painted grating could suffice.

Durability and Maintenance Requirements

Lastly, consider the maintenance requirements of the two options. Hot-dipped galvanized grating typically requires fewer maintenance efforts due to its corrosion resistance. On the other hand, painted steel grating might need regular repainting or touch-ups to maintain its look and prevent rust. Therefore, if ease of maintenance is a priority, hot-dipped galvanizing could be a more appropriate choice.

Cost and Budget Constraints

While hot-dipped galvanized grating can be more expensive initially, its low maintenance and long lifespan often make it more cost-effective in the long run. Painted grating, with lower upfront costs but potentially higher long-term maintenance expenses, might fit a tight budget better but should be considered with the future maintenance cost in mind.

Aesthetic Preferences

For projects where the grating needs to blend with a certain design scheme or color palette, painted grating would be the best choice due to its versatility in color options.

Case Studies

A. Successful Utilization of Hot-Dipped Galvanized Steel Grating

One compelling case study is the implementation of these gratings in the chemical processing industry. Considering the harsh and corrosive nature of many of the substances dealt with in this industry, it was vital to find durable, reliable, and safe flooring. Hot-dipped galvanized steel grating checked all these boxes. It not only withstood the corrosive substances but also provided a safe, non-slip surface for the employees.

Another noteworthy utilisation of hot-dipped galvanized steel grating can be seen in outdoor constructions such as bridges, walkways, and ramps. The strong, durable, and weather-resistant properties of this material make it a top choice for outdoor use. Its longevity, despite exposure to harsh weather conditions, is testament to its effective functionality.

B. Successful Utilization of Painted Steel Grating

Painted steel grating is another versatile grating option that serves a vast range of industries. Its aesthetic appeal combined with its durability makes it a desirable choice.

In recent years, this type of grating has seen significant implementation in the architectural and design industry. Case in point is a modern art museum that employed painted steel grating in its design. The material provided both an artistic appeal and a functional, safe walking surface. The museum staff found this type of grating to be extremely durable, despite the high foot traffic, and its maintenance was straightforward and cost-effective.

An industrial application of painted steel grating is observed in warehouse facilities. Given the heavy machinery and constant movement of goods, this type of grating proved to be strong, durable, and capable of supporting heavy loads.

Additionally, the variety of paint colors allowed for different zone markings, aiding in the efficient organization of the facility. It was also found to be easy to clean, contributing to a safer and more efficient working environment.

Conclusion

Choosing between hot-dipped galvanized steel grating and painted steel grating boils down to the specific needs and circumstances of your project. Both options have their strengths and are suited to different applications.

By considering factors such as environmental conditions, durability requirements, cost constraints, and aesthetic preferences, industry professionals can make a well-informed choice that will meet the demands of their projects efficiently and effectively.