Introduction

If you’re looking for a way to keep your press-locked steel grating in top condition, then you’ve come to the right place! This guide will show you the best way to maintain and care for your press-locked steel grating, ensuring it can last for years to come.

If you need to ensure that press-locked steel grating remains in top condition, this guide will provide the information needed to keep it in its best state.

1. What is a press-locked steel grating

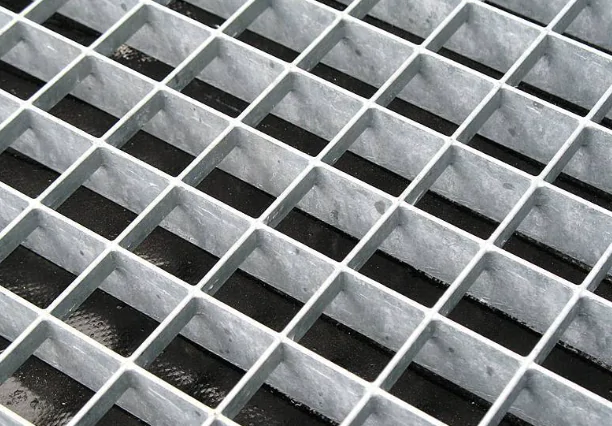

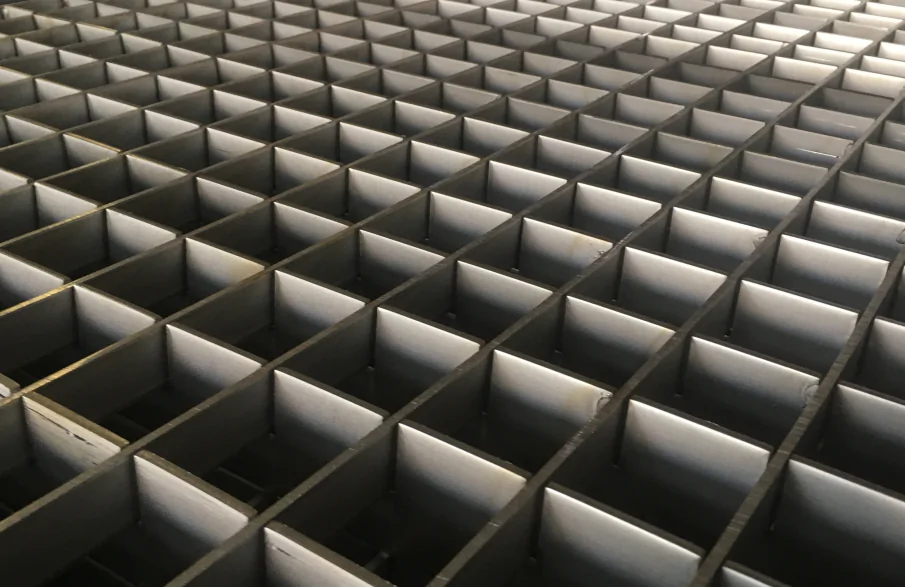

Press-locked steel grating is a type of metal grating with a heavy-duty, flat, and smooth surface. It is constructed by inserting alternating crossed bars into pre-punched, parallel bearing bars. The bearing bars are then permanently locked into place with a hydraulic press.

The bearing bar is made of low-carbon steel, stainless steel, aluminum, and other materials, and the crossbar is made of round steel, square steel, flat steel, and other materials. The two bars are locked together by high pressure. The pressure lock grating has many specifications and can be customized according to customer requirements.

This construction method creates a product that is extremely durable and resistant to wear, corrosion, and other environmental factors. Press-locked steel grating is a kind of metal grating product produced by pressure locking of steel gratings. It is mainly used in bridges, steel structure platforms, floors, trestles, drainage trenches, etc.

The press-locked grating has the characteristics of a beautiful appearance, strong bearing capacity, and lightweight and convenient installation.

- Robust and durable construction

Press-locked steel grating is a type of steel grating that is constructed using a press-locking process to form a tight, strong connection between the bearing bars and cross bars. This construction process creates a robust and durable grating that is ideal for areas that require high strength and durability.

- High slip-resistance

Press-locked steel grating is a cost-effective and popular choice for applications that require a high level of slip resistance. It is made from a combination of two different types of steel, which are cross-clamped together to create a tight, secure connection.

The alternating cross-bars of press-locked steel grating are what give it its superior slip-resistance, as they provide a solid surface with no gaps or edges that could potentially cause slipping.

- Low maintenance

Press-locked steel grating is a great option for many applications due to its relatively low maintenance requirements. Unlike some other grating materials, press-locked steel grating does not need to be painted or treated to last, making it much easier to maintain. Its durable construction also allows it to withstand harsh weather conditions and heavy foot traffic without any need for regular upkeep.

- Corrosion-resistant

Press-locked steel grating is an excellent choice for corrosion-resistant applications. It is made from high-grade steel which makes it resistant to corrosion and other environmental elements.

- Easy installation

Press-locked steel grating is a great choice for any industrial or commercial application due to its easy installation. The installation process is simple, and it can be done with minimal labor and equipment, making it a great choice for any application.

- Variety of sizes and styles to suit different applications

Press-locked steel grating is available in a variety of sizes and styles to suit different applications. The size of the grating is determined by the size of the bars and their spacing, which can range from 3/4″ to 6″ in height, with spacing between bars ranging from 1/4″ to 4″.

2. Available types of press-locked steel grating

Press-locked steel grating is available in a variety of styles, including plain steel, serrated steel, and aluminum.

Plain steel press-locked grating

Plain steel press-locked grating is a simple, economical option that is designed to provide a durable and corrosion-resistant surface. It is often used in areas with heavy pedestrian traffic, such as bridges and stairways, and is available in a variety of sizes and gauges.

Serrated steel press-locked grating

Serrated steel press-locked grating is a more advanced option that offers enhanced slip resistance and traction. This type of grating is ideal for areas where slippery surfaces are a concern, such as stairways, ramps, and public walkways. It is available in a variety of sizes and gauges and can be easily customized to fit specific project needs.

Aluminum press-locked grating

Aluminum press-locked grating is a lightweight, corrosion-resistant option that is often used in industrial applications. It is available in a variety of sizes and gauges to accommodate nearly any application.

Swaged press-locked grating

Swaged press-locked grating is the most popular type. It features a rounded bearing bar with a cross bar that is inserted into the bearing bar and then pressed into place. This construction creates a strong bond between the two bars and results in a smooth, seamless surface.

Flush top press-locked grating

Flush top press-locked grating is similar to swaged press-locked grating but features a flat surface. The top of the grating is flush with the bearing bar so that it can be used in applications where the surface is important. The flush top press-locked grating is mainly used in the food industry, pharmaceutical industry, and other applications requiring a smooth surface.

I-bar press-locked grating

I-bar press-locked grating is similar to dovetail press-locked grating but features an I-shaped bearing bar with a cross bar that is inserted into the bearing bar and then press-locked into place. This design provides a stronger connection than dovetail press-locked grating.

3. How to maintain press-locked steel grating

Clean up the surface

Dirties attached to the surface may accelerate the corrosion of steel gratings, so it is necessary to remove the dirty and clean the press-locked steel gratings regularly

Maintain the surface

Press-locked steel gratings usually have surface treatment due to different practical requirements, whether it is painted or galvanized. And the surface layer may fall off during the application, then it is likely to get corroded, which shortens its life span, as well as affects the flat and beautiful appearance.

Once it does, workers often choose to repair them by re-galvanizing or repainting. And for press-locked steel gratings that are used frequently, regular inspection should be adopted to ensure their good status.

Not beyond load capacity

Press-locked steel grating is a good choice for loading heavy-duty for their construction. So a problem may come: what if it is beyond the load capacity of press-locked steel grating? It is possible to harm and deform them by overloading. And even worse, accident happens for a lack of safety.

Check welded joint

When checking welded joints in maintaining press-locked steel grating, it is important to ensure that the welds are even and consistent. The welds should be visually inspected for any cracks or signs of damage. It is also important to check the depth of the welds and that they have been properly applied.

Additionally, any areas where the grating is not properly locked should be examined and repaired. Lastly, all loose parts should be re-welded and secured in place to ensure the grating is strong and secure.

Conclusion

Maintaining press-locked steel grating is an important part of keeping it looking and performing its best. With regular cleaning and inspections, you can keep it in great shape and enjoy its use for many years.