Introduction

Aluminum wire mesh is a popular choice for a variety of applications due to its many advantages. This versatile material is durable, lightweight, and low maintenance, making it an excellent choice for a range of projects. In this article, we’ll take a closer look at the benefits of aluminum wire mesh and explore some of its most common applications.

Discover the benefits of aluminum wire mesh for a wide range of applications. Find out why it’s an excellent choice for your next project.

1. What is an aluminum wire mesh

Features and Construction

Aluminum wire mesh is a versatile material that has a range of features that make it an ideal choice for a wide range of applications. Some of the key features of aluminum wire mesh include:

- Strength: Despite its lightweight nature, aluminum wire mesh is also strong and durable. It can withstand regular use and exposure to environmental conditions without compromising its structural integrity.

- Versatility: Aluminum wire mesh is highly versatile and can be used for a wide range of applications, including pest control, aerospace, and construction.

- Filtering capabilities: Aluminum wire mesh can be used as an effective filter for air and water, making it ideal for use in ventilation and filtration systems.

Aluminum wire mesh is constructed using a high-quality aluminum wire that is woven into a mesh pattern. The wires are woven together in a criss-cross pattern, creating a strong and durable material.

The wire used to construct aluminum wire mesh is typically made from high-quality aluminum alloy, which provides the material with its strength and durability. The wire is often coated with a protective layer of paint or powder coating to enhance its corrosion resistance and improve its overall durability.

The weaving process used to create aluminum wire mesh involves interlacing the wires in a criss-cross pattern, creating a uniform mesh pattern. This pattern can be customized to create different hole sizes and mesh densities to meet specific requirements.

Once the weaving process is complete, the aluminum wire mesh is typically cut to size and shaped to fit the specific requirements of the application. This can include cutting the mesh to fit the dimensions of a window or door or shaping it to fit the contours of a particular surface.

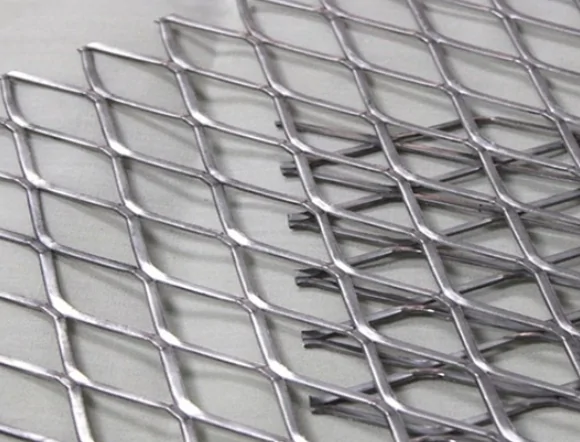

In addition to the standard woven construction, aluminum wire mesh can also be welded or expanded to create a more rigid structure. Welded aluminum wire mesh is created by welding together the intersections of the wire strands, while expanded aluminum wire mesh is created by stretching and flattening the wire strands to create a diamond-shaped pattern.

2. Benefits of aluminum wire mesh

Lightweight

The aluminum wire mesh is lightweight due to the properties of aluminum as a metal. Aluminum is a low-density metal, which means it has a relatively low weight compared to its volume. This makes aluminum wire mesh lighter than other types of a wire mesh made from materials such as steel or copper.

In addition to its low density, aluminum wire mesh is also typically constructed using thin wire strands. These thin wire strands contribute to the lightweight nature of the mesh by reducing the overall weight of the material.

Anti-corrosion

The aluminum wire mesh is anti-corrosive due to the natural properties of aluminum as a metal. Aluminum is highly resistant to corrosion because it readily forms a layer of aluminum oxide on its surface when exposed to oxygen. This layer of aluminum oxide acts as a protective barrier that prevents further corrosion from occurring.

In addition to the natural anti-corrosive properties of aluminum, aluminum wire mesh can also be further protected through various surface treatments such as anodizing or powder coating.

Anodizing involves electrochemically treating the surface of the aluminum wire mesh to thicken the protective layer of aluminum oxide, while powder coating involves applying a protective layer of powder to the surface of the mesh.

These surface treatments not only enhance the natural anti-corrosive properties of aluminum, but they also provide additional protection against other types of damage such as scratches, abrasions, and UV radiation.

Durable

The aluminum wire mesh is durable due to the properties of aluminum as a metal. Aluminum is a strong and durable material that can withstand a range of environmental conditions, making it an excellent choice for applications that require strength and longevity.

In addition to its inherent strength and durability, aluminum wire mesh is typically constructed using a woven pattern that creates a sturdy and robust structure. This structure can withstand the stresses and strains of regular use, as well as exposure to outdoor and marine environments.

Furthermore, aluminum wire mesh is resistant to a range of damage types, including corrosion, abrasions, and impacts. This resilience means that the mesh can maintain its structural integrity and aesthetic appearance over time, even in demanding applications.

Highly malleable

The aluminum wire mesh is highly malleable due to the properties of aluminum as a metal. Aluminum is a relatively soft and ductile material, which means that it is easy to shape and form without breaking.

In addition to its inherent malleability, aluminum wire mesh is typically constructed using thin wire strands that can be easily manipulated into different shapes and sizes. This makes the mesh highly adaptable to a range of applications where customization is required.

The malleability of aluminum wire mesh also makes it easy to install and work with, as it can be easily cut, bent, and shaped to fit specific requirements. This means that it can be quickly and easily installed in a range of applications without the need for complex equipment or tools.

3. Applications of aluminum wire mesh

Pest control

Aluminum wire mesh is commonly used in pest control applications as an effective barrier to prevent insects and rodents from entering buildings and other structures. The mesh is often used to create window screens, door screens, and ventilation covers to prevent pests from entering through these openings.

One of the key advantages of using aluminum wire mesh for pest control is its durability and resistance to corrosion. This makes it an ideal choice for outdoor applications where exposure to the elements is a concern.

Aluminum wire mesh is also highly effective at preventing pests from entering buildings while still allowing for airflow and ventilation. This can be especially important in applications such as commercial kitchens and food processing facilities where maintaining a clean and pest-free environment is critical.

In addition to its use in building openings, aluminum wire mesh can also be used in pest control applications to create physical barriers around gardens and crops. This can prevent pests such as rabbits, squirrels, and birds from damaging plants and crops.

In aerospace

Aluminum wire mesh is widely used in aerospace applications due to its lightweight and strong characteristics. It is used in a range of applications, including aircraft cabin and cargo compartment dividers, ventilation and filtration systems, and electromagnetic shielding.

One of the key advantages of using aluminum wire mesh in aerospace applications is its lightweight nature. The use of lightweight materials in aerospace is critical for reducing the overall weight of the aircraft and improving fuel efficiency. Aluminum wire mesh is significantly lighter than other materials, such as steel or copper, making it an ideal choice for aerospace applications.

In addition to its lightweight properties, aluminum wire mesh is also strong and durable. This means that it can withstand the stresses and strains of flight, as well as exposure to extreme temperatures and environmental conditions.

Aluminum wire mesh is also effective at filtering out debris and particles in the air, making it an ideal choice for use in ventilation and filtration systems in aircraft. Additionally, it can be used for electromagnetic shielding to protect sensitive electronic equipment from interference.

In construction

Aluminum wire mesh is widely used in construction applications as a versatile and reliable material. It is commonly used for a range of purposes, including safety barriers, fencing, cladding, and decorative elements.

One of the key advantages of using aluminum wire mesh in construction is its strength and durability. Aluminum wire mesh can withstand the stresses and strains of regular use, as well as exposure to environmental conditions such as rain, wind, and extreme temperatures.

Aluminum wire mesh is also highly versatile, with the ability to be easily cut and shaped to fit specific requirements. This makes it an ideal choice for a range of applications where customization is required.

In addition to its practical uses, aluminum wire mesh is also commonly used for decorative purposes in construction. It can be used to create unique and eye-catching designs on facades, walls, and other surfaces.

Another advantage of using aluminum wire mesh in construction is its corrosion resistance. This makes it an ideal choice for outdoor applications where exposure to the elements is a concern.

Conclusion

Aluminum wire mesh is a versatile and practical material that offers a range of advantages, including its lightweight nature, strength and durability, resistance to corrosion, malleability, and filtering capabilities. These features make it an ideal choice for a wide range of applications in pest control, aerospace, construction, and beyond.