Lead-in

Aluminum grating is a versatile and durable material that is used in various industries for its lightweight, high-strength, and corrosion-resistant properties. From industrial flooring to pedestrian walkways, aluminum grating has become an essential component in many applications. If you’re curious to know more about this material and its benefits, applications, and more, then you’ve come to the right place.

In this Ultimate Guide to Aluminum Grating, we will explore everything you need to know about this material and how to choose the right type for your specific needs. So, let’s dive in!

1. Benefits of Aluminum Grating

Aluminum grating offers several benefits, including:

Lightweight and easy to handle

Aluminum grating is significantly lighter than steel, which makes it easier to handle and install. Its lightweight nature also reduces the load on supporting structures, making it an ideal choice for applications where weight is a concern.

High strength-to-weight ratio

Despite its lightweight, aluminum grating has a high strength-to-weight ratio, which makes it strong enough to support heavy loads. This property makes it ideal for high-traffic areas that require a durable and reliable material.

Corrosion-resistant

Aluminum grating is highly resistant to corrosion, which makes it suitable for outdoor or wet environments. It doesn’t rust or corrode, making it a long-lasting and reliable choice for various applications.

Fire-resistant

Aluminum grating has excellent fire-resistant properties, which makes it a safe choice for applications where fire is a concern.

Non-magnetic

Unlike steel, aluminum grating is non-magnetic, making it an ideal choice for applications where magnetic interference is a concern.

2. Types of Aluminum Grating

There are three main types of aluminum grating, each with its own unique characteristics and advantages. These types include:

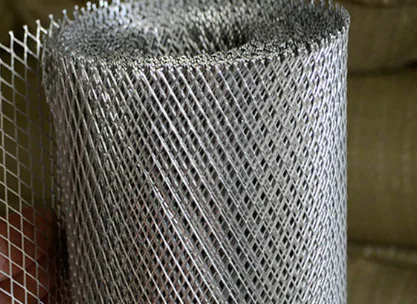

Swage-locked grating

Swage-locked grating is manufactured by inserting a series of round bars into rectangular bearer bars and then swaging the bars together. This process creates a strong and durable grating that is resistant to high loads and impacts. Swage-locked grating has a smooth surface and a clean appearance, making it an ideal choice for architectural applications.

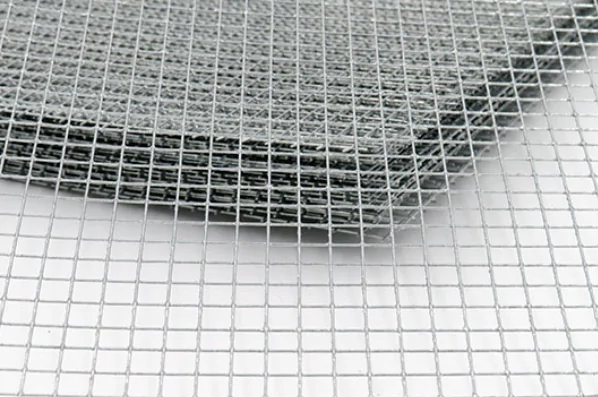

Press-locked grating

Press-locked grating is manufactured by inserting cross bars into pre-punched rectangular or round bearer bars and then pressing the bars together under high pressure.

This process creates a rigid and durable grating that is resistant to high loads and impacts. Press-locked grating has a uniform appearance and a high slip resistance, making it an ideal choice for industrial applications.

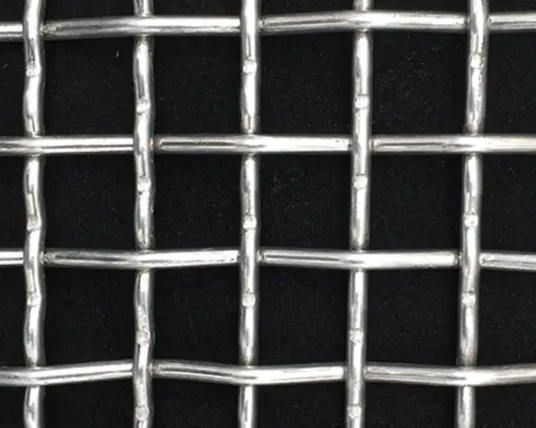

Riveted grating

Riveted grating is manufactured by inserting round bars into pre-punched rectangular or round bearer bars and then riveting the bars together using high-pressure hydraulic presses. This process creates a grating that is highly resistant to impact and fatigue.

Riveted grating has a rugged appearance and a high load-bearing capacity, making it an ideal choice for heavy-duty applications.

3. Applications of Aluminum Grating

Aluminum grating is widely used in various industries for its durability, strength, and corrosion-resistant properties. Some common applications of aluminum grating include:

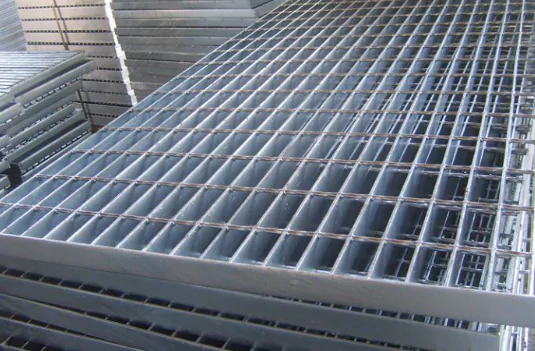

Industrial flooring

Aluminum grating is an ideal choice for industrial flooring due to its durability, strength, and slip resistance. It can be used in various industries, including manufacturing, food processing, and chemical processing.

Catwalks and mezzanine platforms

Aluminum grating is often used in catwalks and mezzanine platforms due to its lightweight nature, ease of installation, and high strength-to-weight ratio. It can be used in various industries, including manufacturing, transportation, and warehousing.

Stair treads and nosing

Aluminum grating is an ideal choice for stair treads and nosing due to its slip resistance, durability, and low maintenance. It can be used in various industries, including commercial and industrial buildings, airports, and transportation.

Drainage covers and trench covers

Aluminum grating is often used as drainage covers and trench covers due to its high load-bearing capacity and corrosion-resistant properties. It can be used in various industries, including transportation, construction, and infrastructure.

Security fencing and barriers

Aluminum grating is an ideal choice for security fencing and barriers due to its strength, durability, and corrosion-resistant properties. It can be used in various industries, including transportation, energy, and public safety.

Pedestrian walkways and bridges

Aluminum grating is often used in pedestrian walkways and bridges due to its lightweight nature, slip resistance, and ease of installation. It can be used in various industries, including transportation, architecture, and infrastructure.

Aluminum grating is a versatile material that offers a wide range of applications in various industries. Its unique combination of properties makes it an essential component in many applications that require durability, strength, and corrosion resistance.

4. Choosing the Right Aluminum Grating

Choosing the right type of aluminum grating for a specific application requires careful consideration of several factors. Some of the factors to consider when choosing aluminum grating include:

Load-bearing capacity

The load-bearing capacity of the grating is an important factor to consider, as it determines the weight that the grating can support. The load-bearing capacity depends on the span of the grating, the size of the bearer bars, and the type of grating used.

Span and deflection

The span and deflection of the grating determine the distance between the supporting structures and the amount of flex or deformation that the grating can tolerate. The span and deflection depend on the size of the bearer bars, the type of grating used, and the load-bearing capacity of the grating.

Open area and slip resistance

The open area and slip resistance of the grating are important factors to consider for applications where liquids or debris may accumulate on the surface. The open area determines the amount of liquid or debris that can pass through the grating, while the slip resistance determines the level of traction and grip that the surface provides.

Surface finish and aesthetics

The surface finish and aesthetics of the grating can vary, depending on the type of grating used. The surface finish can range from smooth to serrated, while the aesthetics can range from utilitarian to decorative.

Customization options

Aluminum grating can be customized to meet specific needs, including the size of the bearer bars, the spacing between the bars, and the type of grating used. Customization options can vary depending on the manufacturer and the type of grating used.

Choosing the right type of aluminum grating requires careful consideration of several factors to ensure that the grating meets the specific needs of the application. It is important to work with a reputable manufacturer or supplier who can provide guidance and support in selecting the appropriate grating for the application.

5. Installation and Maintenance of Aluminum Grating

A. Installation

Preparation

Before installing aluminum grating, the following preparations should be made:

- Verify the type, size, and quantity of aluminum grating specified in the project plans and ensure that they comply with the applicable codes and standards.

- Ensure that the supporting structure is capable of supporting the weight of the grating and any anticipated loads.

- Ensure that the supporting structure is level and free of any debris or protrusions that could interfere with the installation.

- Ensure that all required tools, equipment, and materials are available on site.

Installation Procedure

The following steps should be followed when installing aluminum grating:

- Lay out the grating panels according to the project plans, ensuring that they are properly oriented and spaced as required.

- Secure the grating panels to the supporting structure using appropriate fasteners and hardware, such as saddle clips or hold-down clips.

- Install any necessary edge trim or nosing as required to provide a finished appearance and to prevent tripping hazards.

- Verify that the installed grating is level and secure.

B. Maintenance

Inspection

Regular inspections should be conducted to ensure that the aluminum grating is in good condition and functioning as intended. The following items should be checked during inspections:

- The condition of the grating panels, including any signs of corrosion, cracking, or deformation.

- The condition of any edge trim or nosing, including any signs of damage or wear.

- The condition of any fasteners or hardware, including any signs of loosening or corrosion.

- Cleaning

- To maintain the appearance and functionality of aluminum grating, regular cleaning should be performed using a mild detergent and water. Harsh chemicals or abrasive cleaners should be avoided, as they can damage the grating’s surface.

Repairs

If any damage or defects are found during inspections, they should be repaired promptly to prevent further deterioration or safety hazards. Repairs may involve replacing individual grating panels, edge trim or nosing, or fasteners and hardware as necessary.

Proper installation and regular maintenance are important to ensure the safe and effective use of aluminum grating. By following the recommended procedures, the longevity and performance of the grating can be maximized.

Conclusion

As the demand for sustainable and environmentally friendly materials increases, aluminum grating has become a popular choice due to its recyclable and sustainable nature. The future outlook for the use of aluminum grating in various industries is promising, as the demand for durable and reliable materials continues to grow.

In conclusion, aluminum grating is an essential component in many industries, and understanding its benefits, applications, and selection criteria is crucial for successful implementation in various applications.