Introduction

As a durable and corrosion-resistant metal grating, electroplated steel grating has various applications in various industries, including construction, transportation, and manufacturing.

Whether you are a seasoned professional or just starting to explore the world of electroplated steel grating, we have something for everyone. This article will delve into the world of electroplated steel grating and explore its uses, benefits, and production process.

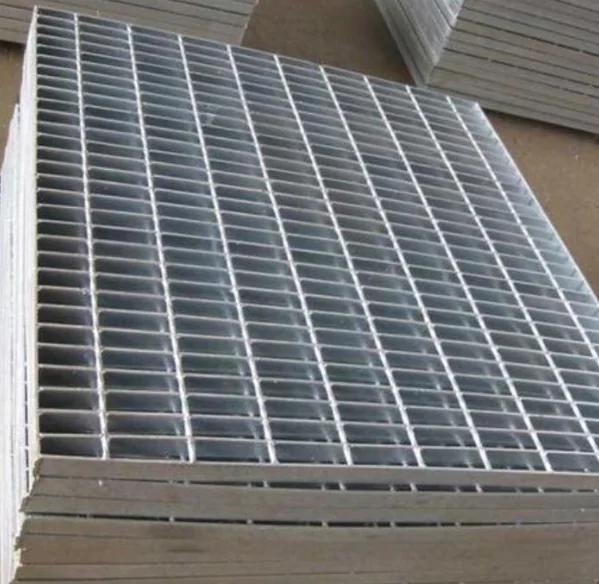

1. What is Electroplated steel grating

Electroplated steel grating is a type of metal grating made by electroplating a thin layer of another metal or alloy onto the surface of carbon steel. The process of electroplating involves using electrolysis to attach the metal film to the surface of the grating using metal ions. This helps to improve the grating’s resistance to corrosion and its overall durability.

It is often used in industrial and manufacturing environments where it is subjected to harsh conditions, such as coastal areas or offshore environments. It is also used in areas where corrosion resistance is required, such as in chemical processing plants.

The grating is typically made up of bearing bars, which are welded metal bars that provide the main load-bearing structure, and cross bars, which are used to hold the bearing bars in place. The electroplating process is typically applied to these bars to provide an even and consistent layer of protection against corrosion.

The adjacent parts of the grating are also electroplated to ensure that the entire grating has a consistent level of protection against corrosion.

Its open design allows for maximum airflow, benefiting various industries, such as agriculture and manufacturing. Electroplated steel grating is also available in various metal finishes, such as zinc or copper, which can enhance its aesthetic appeal.

2. The benefits of electroplated steel grating

| Corrosion resistance | The electroplating process creates a thin layer of metal on the surface of the grating, which helps to prevent rust and other forms of corrosion. |

| Improved safety | The smooth surface of the grating reduces the risk of slips and falls, and the narrow opening between the bearing bars can help to prevent objects from falling through. |

| Enhanced airflow | Its open design allows for maximum airflow, which can be beneficial in various industries, such as agriculture and manufacturing. |

| Multiple layers | It can be created with multiple layers of metal, further improving its corrosion resistance and overall durability. |

| Efficient process | The electroplating process is relatively efficient, allowing a thin layer of metal to be applied to the grating surface using metal ions. This is in contrast to hot dipping, which involves submerging the entire grating piece in a molten metal bath. |

3. How to apply electroplated steel grating

Step 1

Choose the appropriate plating material. There are several different types available, including zinc plating, copper, and nickel. It is important to choose a suitable type for the intended application, taking into account factors such as the level of resistance needed and the desired aesthetic appearance.

Step 2

Prepare the surface of the grating for the electroplating process. This typically involves performing some form of surface treatment, such as abrasive blasting or chemical cleaning, to remove any contaminants or debris from the surface of the grating.

Step 3

Set up the electroplating equipment. This will typically include a power supply, a tank for the electroplating solution, and a cathode and anode. The grating will serve as the cathode, while the anode will be made of the metal that is being used for the electroplating process, such as zinc or copper. After setting up, place the grating.

Step 4

Apply the electric current. The power supply is then used to apply an electric current to the solution, which causes the ions in the solution to be attracted to the surface of the grating. This results in a thin layer of metal being deposited on the surface of the grating.

Step 5

Remove the grating from the solution and dry it. Once the desired thickness of the electroplated layer has been achieved, the grating can be removed from the solution and rinsed with water to remove any excess solution.

Conclusion

Electroplated steel grating is a type of metal grating that is made by applying a thin layer of another metal or alloy to the surface of carbon steel using the principle of electrolysis. It is a durable and corrosion-resistant option for a variety of applications, including as a flooring system, a platform, or a walkway. The plating process is typically applied to both the bearing bars and the cross bars to provide an even and consistent layer of protection.