Have you ever walked past a drainage system and wondered about the function of the steel structures covering them? These are steel gratings, and they play an essential role in urban infrastructure. Their importance may seem trivial but without them, city streets could be overwhelmed with rainwater, causing discomfort and potential hazards for pedestrians and motorists alike.

Steel grating for drainage is a framework of parallel and perpendicular metal bars, typically made from steel due to its durability and strength. This grid-like structure is designed to cover drains and sewer systems, acting as a filter to prevent large debris from entering while still allowing the flow of water and smaller particles. This helps to prevent blockages and maintains the functionality of the drainage system, making steel grating an indispensable component of urban infrastructure.

After understanding the fundamental role of steel grating in drainage systems, you may realize how these overlooked structures work silently, making our urban environments cleaner and safer. Now, are you curious to dive deeper into the world of steel gratings and their various aspects such as types, design, construction, and installation? If so, read on as we unfold these intriguing details.

1. What is Steel Grating for Drainage?

Steel grating is an indispensable material in construction and other industries. It performs many roles from being an integral part of machinery to providing a pathway for people, and even enabling efficient drainage systems. Understanding steel grating better will help you appreciate its versatility and broad range of uses.

Detailed Definition and Properties of Steel Grating for drainage

Steel grating is a series of bearing bars and cross rods welded or otherwise joined at various intersections to form a solid and uniform structure. One significant characteristic of steel grating is its open design which allows for the passage of light, air, and particles. It is this open yet resilient structure that makes it an excellent choice for multiple functions across different industries.

In terms of properties, steel grating stands out because of its impressive durability, strength, and load-bearing capability. It is also recognized for its high grip, ensuring secure footing and reducing the risk of slips and falls. What’s more, with its corrosion-resistant property, it provides an excellent defense against harsh environmental conditions, ensuring a long lifespan even in the face of continuous use.

2.Types and Features of Steel Grating for Drainage

During my many years of working on city infrastructure projects, I’ve been fortunate to develop a deep understanding of various aspects of urban planning, including the importance and versatility of steel grating for drainage systems.

When it comes to steel grating, there’s no one-size-fits-all solution. The type used often depends on the specific requirements of the drainage system. Some of the most commonly used types include welded steel grating, press-locked steel grating, riveted steel grating, and close mesh steel grating. Each comes with unique characteristics and benefits.

Welded steel grating, for example, is renowned for its strength and durability. It’s an excellent choice for areas with high traffic or heavy loads. On the other hand, press-locked steel grating offers a smooth, aesthetically pleasing surface, ideal for areas where visual appeal is a priority. Riveted steel grating is known for its exceptional load-bearing capability, while close mesh steel grating provides an anti-slip surface, making it a preferred choice for slippery or wet conditions.

Having worked with these various types of steel grating, I can attest to the importance of selecting the right one for each project. The selection criteria typically include drainage requirements, load-bearing capacity, local climate, safety considerations, and budget. Making the right choice can significantly enhance the efficiency of the drainage system and reduce long-term maintenance costs.

I’ve shared this information in the hopes that it not only gives you a deeper understanding of steel grating but also allows you to appreciate the thought and expertise that goes into making our cities safer and more efficient. Remember, in city planning and infrastructure, even the most seemingly trivial details can have a profound impact on the functionality and safety of our urban spaces.

3. The Role of Proper Drainage in Building Projects

Drainage is paramount in any construction project. It’s as important as the foundation, structure, and design elements, sometimes even more so. Working with urban infrastructures for several years has allowed me to appreciate the unnoticed yet essential components that keep our cities functioning smoothly. One such element is the steel grating in drainage systems.

Steel grating plays a crucial role in managing water and waste flow. Picture a heavy downpour in a bustling city. The city’s drainage system provides an essential path for the rainwater, helping prevent flooding. However, this water often carries debris, trash, leaves, which pose the risk of clogging the system.

Here, steel grating serves as the first line of defense. The grating’s grid-like design acts as a sieve, permitting water and smaller particles to pass while effectively filtering out larger waste. This intelligent, yet simple mechanism ensures a consistent, unhindered flow into the drainage system, thus averting potential blockages and overflows.

Without an effective drainage system, a building is left vulnerable to a plethora of problems. Undrained water can lead to soil erosion around the structure, leading to unstable foundations and grounds. Moreover, water infiltration can result in moisture damage, including damp walls, mold growth, and rotting of building materials.

In more severe cases, standing water can lead to flooding, causing significant damage to property and disruption of activities within the building. Over time, repeated exposure to moisture can lead to structural weakening and failure, posing serious safety risks.

4. How Steel Grating for drainage Can Solve These Problems

| Features | Application |

| Open design | Allows water to pass through |

| Galvanizing layer | Withstands harsh weather conditions |

| High load capacity | Bear heavy load |

| Study status | Undergo the continual flow of water without corroding or wearing out |

Thanks to its high strength, durability, and excellent water drainage capabilities, steel grating can effectively prevent the accumulation of water.

There are specific features of steel grating that make it perfectly suited to drainage applications. The open design of steel grating allows water to pass through easily, making it ideal for use in drainage systems. This feature ensures that surface water is efficiently captured and redirected, preventing unwanted pooling of water. It withstands harsh weather conditions and heavy loads, making it ideal for both indoor and outdoor use.

Moreover, steel grating is also easy to install and requires minimal maintenance, providing an efficient and cost-effective solution for drainage issues. Therefore, considering steel grating in construction projects can save both time and cost while ensuring the long-term safety and integrity of the building.

In addition, the durability of steel grating means that it can withstand the continual flow of water without corroding or wearing out, thus ensuring longevity. Coupled with its high load-bearing capacity, it can handle not just the water’s weight but also the additional load from pedestrian or vehicle traffic.

The design of steel grating for effective drainage involves several essential elements. First and foremost, the sizing and spacing of the bars should be such that they allow water to flow freely while trapping larger debris.

Second, the grating’s surface often features a non-slip design for pedestrian safety, especially in wet conditions. Finally, considerations are made for the grating’s weight-bearing capacity, depending on whether it will be installed in pedestrian areas, vehicle traffic zones, or heavy load areas.

5. Benefits of Using Steel Grating for Drainage

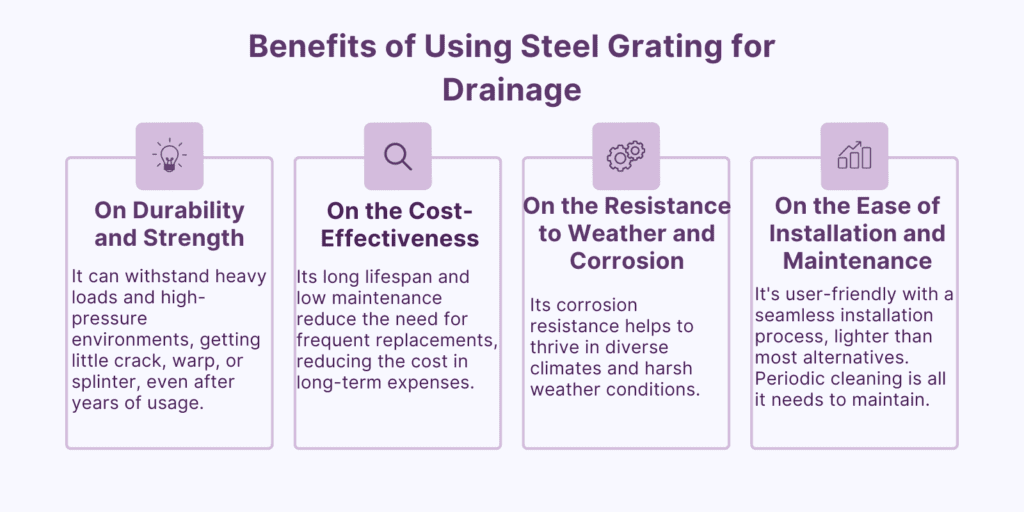

Steel grating for drainage systems has become an increasingly popular choice for a variety of reasons. It provides strength and durability, cost-effectiveness, and resistance to weather and corrosion. It is also easy to install and maintain. Additionally, using steel grating can improve the overall performance and longevity of your project.

A. On Durability and Strength

One of the primary benefits of steel grating is its unmatched durability and strength. Expertly designed, its sturdy nature can withstand heavy loads and high-pressure environments, making it ideal for industrial applications. Unlike other materials, steel grating doesn’t crack, warp, or splinter, ensuring constant performance even after years of heavy usage.

B. On the Cost-Effectiveness

Despite its high-end capabilities, steel grating is surprisingly cost-effective. Its long lifespan reduces the need for frequent replacements, providing a significant reduction in long-term expenses. Additionally, steel grating requires less maintenance and repairs compared to other options, saving you both time and money.

C. On the Resistance to Weather and Corrosion

Steel grating is the ultimate in weather and corrosion resistance. It can thrive in diverse climates and harsh weather conditions without compromising its structural integrity and overall appearance. This quality can be further enhanced by applying protective coatings, making your drainage system virtually immune to weather and corrosion-related damages.

D. On the Ease of Installation and Maintenance

Steel grating is designed to be user-friendly with a seamless installation process. It is lighter than most alternatives and can be easily maneuvered into position. Moreover, its uniform design allows for quick and easy replacements, should they ever be necessary. When it comes to maintenance, periodic cleaning is all it needs to maintain its overall appearance and performance.

6 Choosing the Right Steel Grating drainage Manufacturer or Supplier

Your grating’s quality heavily depends on the manufacturer or supplier you choose. Here are a few tips to guide you in making your decision.

- Ensure the supplier has a track record of delivering high-quality steel grating. You can do this by checking their customer reviews or asking for references.

- Evaluate the supplier’s after-sale services. These could include delivery, installation, and maintenance services.

- Ascertain that the supplier meets all relevant industry regulations and quality standards. A supplier who doesn’t adhere to such standards may end up supplying poor quality steel grating.

7. How to Install Steel Grating for Drainage

Whether you are a professional installer or an individual aiming to complete your own project, installing steel grating for drainage can seem to be a daunting task. Yet, with the right knowledge and tools, it can be made easy. In this section, we will guide you through a step by step process for installing steel grating for drainage, followed by tips to maintain your steel grating effectively.

A. Step-by-step guide to installing steel grating for drainage

1. Determine Desired Placement: The initial step involves deciding where you want to install the steel grating. Determine the appropriate area needing drainage. For instance, it could be in your driveway, garden, or even indoors.

2. Measuring and Cutting: Measure and mark the area where the grating will be installed. This will correspond to the dimensions of your steel grating. Use a cutting tool that is appropriate for steel.

3. Digging the Trench: The next step is to dig a trench corresponding to the dimensions you have marked. Make sure the trench is slightly deeper and wider than the grating to allow for adjustments.

4. Placing the Grating: Position your steel grating within the trench. Ensure it’s level and aligns with the surrounding surface.

5. Anchoring the Grating: Use anchoring accessories to secure the steel grating into place. These could be clips or bolts which firmly hold the grating so it doesn’t shift.

6. Testing: Finally, test the drain to ensure that it is functioning correctly. Pour water into the grating, and observe to see if the water drains correctly.

B. Maintenance tips for long-lasting effectiveness

| 1. Regular Cleaning | Over time, debris can accumulate in your drain. Regularly unclog it to maintain the effectiveness of the drain. |

| 2. Rust inspection | Inspect the grate regularly for rust and take appropriate action if any is found. |

| 3. Routine check | Perform routine checks on the anchoring accessories to ensure they are securely holding the grating. |

8. Case Studies: Success Stories of Using Steel Grating for Drainage

In this section, we delve into some real-world applications where the use of steel grating significantly improved a project.

Case Study: Implementing Steel Grating for Drainage in a Large Industrial Park

In my role as the infrastructure manager for the Central Industrial Park, I faced a significant challenge. Our park, sprawling over 2,000 acres, was plagued by severe drainage issues. The existing concrete system was ineffective, leading to costly and disruptive flooding during heavy rainfall.

In search of a durable, cost-effective solution, I decided to replace the concrete with steel grating. We opted for high load-bearing, galvanized steel grating, designed to efficiently handle substantial water flow without succumbing to rust.

The change was transformative. The steel grating flawlessly managed the water runoff, drastically reducing instances of flooding, even during the heaviest of rainfalls. Its durability stood the test of time, showing no signs of years post-installation, saving us significantly on maintenance costs.

Reflecting on my experience, I believe steel grating is a superior solution for effective drainage systems, blending robust functionality with economical longevity. It has been an invaluable asset in managing the industrial park’s infrastructure.

Conclusion

The application of steel grating in drainage systems illustrates the significant difference that a quality material can make in a project’s success. Durable, strong, corrosion-resistant, and capable of handling high loads, steel grating emerges as a superior choice in heavy-duty settings.

This guide aimed to highlight the advantages of steel grating for drainage and inspire professionals to consider this effective material for their projects. In our evolving industry, innovative solutions like steel grating propel us towards continuous improvement in project outcomes.