Introduction

Walkway gratings are an essential feature in numerous architectural and industrial applications. They are grid-like structures composed of metal or fiberglass bars. These bars intersect at regular intervals, creating a sturdy yet permeable platform used in various settings.

They offer a robust and secure surface that can withstand harsh conditions while providing safety, durability, and functionality. This article delves into the depths of walkway gratings, providing critical insights that will help you in your next project.

II. The Basics of Walkway Gratings

A. Materials Used in Walkway Gratings

Walkway gratings are fabricated from various materials, each having unique properties that make them suitable for different applications.

| Material | Properties & Applications |

|---|---|

| Steel | Excellent strength-to-weight ratio. Ideal for high strength requirements in industrial environments. |

| Stainless Steel | High resistance to corrosion, suitable for chemically harsh or high-moisture environments. Aesthetically appealing, perfect for architectural applications. |

| Aluminum | Lightweight, corrosion-resistant, easy to work with. Ideal for commercial projects where weight and aesthetics are significant. |

| Fiberglass | Superior resistance to corrosion, chemicals, UV radiation. Non-conductive, slip-resistant, suitable for electrical and marine applications. |

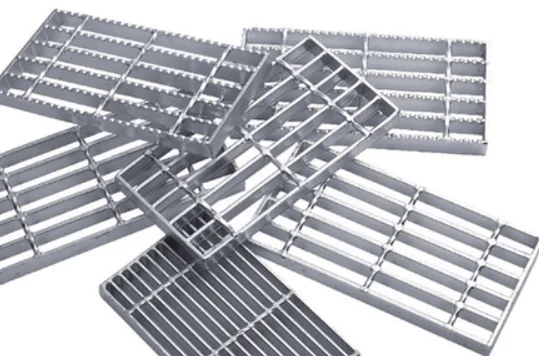

B. Different Types of Gratings

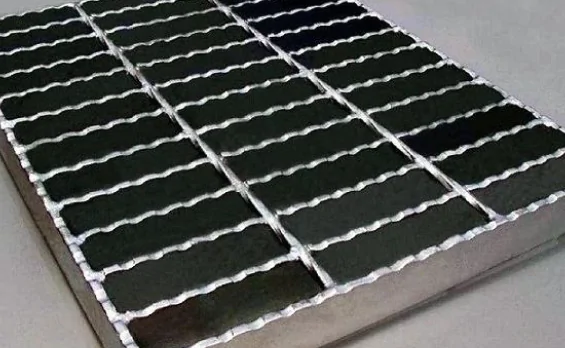

1. Press-Locked Steel Grating

Press-locked steel grating is fabricated by notching steel bars before high hydraulic pressure is applied to lock them into place. This method creates a smooth-surfaced, high-load-bearing grating.

Its aesthetic appeal makes it a popular choice for public spaces, while its strength makes it suitable for heavy load-bearing applications like docks and warehouses. Precise dimension control is another advantage, facilitating use in complex designs and specialized industrial needs.

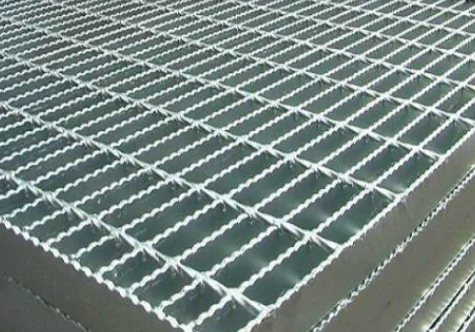

2. Welded Steel Grating

Welded steel grating is made by welding cross rods to the bearing bars, forming a robust structure. Known for its exceptional strength and durability, it’s ideal for heavy-duty applications such as industrial platforms and bridges.

Its slip-resistant surface, especially when serrated, enhances safety in potentially hazardous or slippery areas. The open-grid design allows for excellent drainage and ventilation, making it beneficial in settings where liquids or gases need to pass through the walkway.

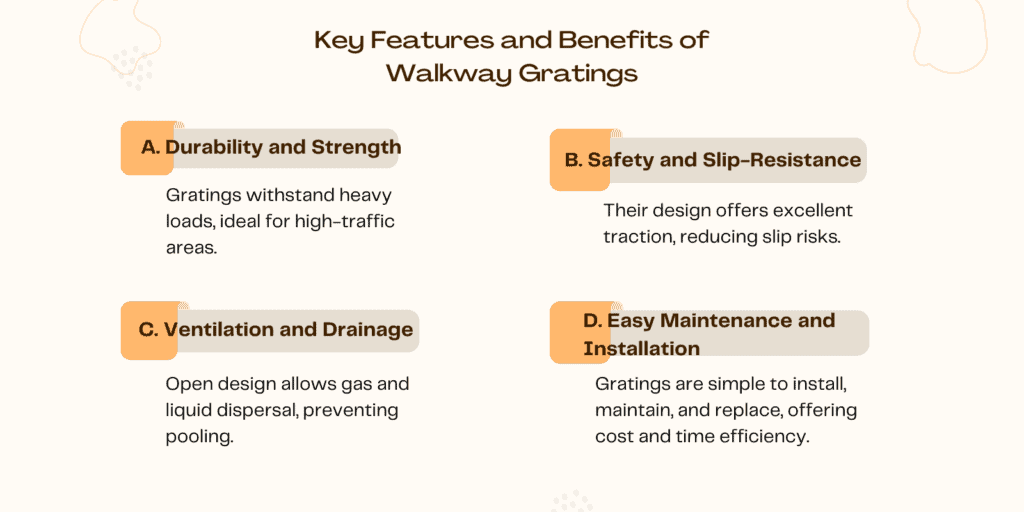

III. Key Features and Benefits of Walkway Gratings

Walkway gratings, whether used in industrial environments or for architectural designs, bring a host of benefits to any project. These include:

A. Durability and Strength

Walkway gratings, particularly those made from metals like steel or aluminum, are incredibly durable and robust. They’re built to withstand heavy loads and prolonged use, which makes them ideal for high-traffic or weight-bearing areas. The strength of these gratings ensures they can support industrial equipment, vehicular traffic, or pedestrian movement without succumbing to structural damage.

B. Safety and Slip-Resistance

One of the most critical benefits of walkway gratings is their contribution to safety. The grid-like design of gratings provides excellent traction, which significantly reduces the risk of slips and falls. Moreover, certain types of gratings, such as serrated bar gratings or those with specially designed surfaces, offer additional slip resistance, an essential factor in wet or oily conditions.

C. Ventilation and Drainage

The open design of walkway gratings facilitates both ventilation and drainage. In industrial settings, this can help disperse potentially harmful gases or heat. Additionally, the grating allows water or other liquids to drain away, preventing pooling that can cause slips or corrosion. This feature also allows light to pass through, improving visibility in certain applications.

D. Easy Maintenance and Installation

Walkway gratings are comparatively simple to install, with many variants designed for easy fitting onto support structures. They require minimal maintenance, usually only periodic inspections and cleaning, and their modular design allows damaged sections to be replaced without disrupting the entire structure. This simplicity translates into cost and time efficiency, making gratings a practical choice for many projects.

IV. Choosing the Right Grating for Your Project

Selecting the ideal grating for your project is a crucial process that necessitates careful consideration of multiple factors.

A. Factors to Consider

- Firstly, load requirements are vital. The grating should be capable of withstanding the maximum load it will regularly encounter, whether from foot traffic, vehicles, or heavy machinery. It’s essential to assess the nature and frequency of the load to select a grating with the right strength and durability.

- Slip resistance is another crucial factor, particularly in environments prone to wet or oily conditions. Opting for gratings with anti-slip surfaces, such as serrated or gritted ones, can significantly enhance safety.

- Corrosion resistance should also be prioritized, especially for projects exposed to elements or corrosive substances. Stainless steel or fiberglass gratings, or those with protective coatings, offer enhanced resilience against corrosion.

- Additional considerations may include aesthetic appeal, cost-effectiveness, and compliance with local building codes or industry regulations.

B. Customization Options

Once you’ve identified the critical attributes for your project, consider customization options to further tailor the grating to your needs.

Coatings such as galvanization or powder coating can improve the grating’s longevity by providing an extra layer of protection against wear and corrosion.

Finishes can also be applied to gratings, enhancing their appearance and sometimes their functionality. For instance, a polished finish can give stainless steel gratings a sleek, modern look, while a gritted finish can increase slip resistance.

V. Installing and Maintaining Your Walkway Gratings

The lifespan and performance of your walkway gratings heavily depend on correct installation and regular maintenance.

A. General Process of Installation

Installing walkway gratings generally involves measuring and marking the area where the grating will be placed, securing the grating to its supports, and ensuring it’s level and stable. Often, the gratings are placed onto a pre-constructed frame or supports and fastened using specific grating clips or bolts.

It’s crucial to follow the manufacturer’s instructions or consult a professional to ensure that the installation process is done correctly, as improper installation can lead to instability or premature wear.

B. Safety Precautions During Installation

Safety should be a top priority during the installation process. It is important to use appropriate safety gear, including gloves, safety glasses, and hard hats, especially when cutting or fastening the grating. Ensure the installation area is clear of obstacles, and be aware of your surroundings to prevent accidents. It is also crucial to use the right tools and equipment for the job, and ensure that the grating is secure before allowing traffic.

C. Guidelines for Maintenance and Inspection

| Inspection | Inspect for signs of wear, corrosion, or damage, such as bending, cracking, or loose fasteners |

| Maintenance | Routine cleaning, remove debris or rust with a wire brush and apply rust-proof paint; stay within the weight limits specified and replace them if necessary |

To conclude, the correct installation and diligent maintenance of walkway gratings are essential to maximize their lifespan, ensure their safe operation, and maintain their performance over time.

VII. Case Studies: Successful Projects Using Walkway Gratings

Walkway gratings have been successfully integrated into numerous projects, demonstrating their versatility and effectiveness across various industries.

A. Description of a Few Successful Projects

Industrial Plant: In a large petrochemical facility, heavy-duty welded steel gratings were used to construct walkways around machinery for safe and easy access. Despite constant exposure to harsh chemicals and heavy equipment, the gratings proved their resilience and strength, ensuring safe movement around the plant.

Public Park: In a renovation of a public park, press-locked gratings were installed over water features and as bridges over small ravines. Their aesthetic appeal complemented the park’s design, while their durability withstood heavy public use. The grating’s open design also allowed light and water to pass through, preserving the park’s natural environment.

B. Lessons Learned and Best Practices

From these projects, we can draw several lessons and best practices.

Right Material for the Environment: The choice of material is critical. For instance, the industrial plant required high-strength, corrosion-resistant steel gratings, while the public park benefitted from the aesthetic and environmental compatibility of press-locked gratings.

Regular Maintenance: Both projects underlined the importance of regular maintenance. In the petrochemical plant, timely inspections helped spot potential issues, while in the park, regular cleaning kept the gratings in optimal condition.

Safety is Paramount: Safety was a priority in both projects. The plant ensured high traction surfaces for its grating to prevent slips, while the park chose gratings with close bar spacing to ensure safety for all, including children and pets.

In conclusion, walkway gratings have proven to be a successful choice in diverse settings. By selecting the right type and material, prioritizing safety, and ensuring regular maintenance, walkway gratings can offer a durable, practical, and aesthetically pleasing solution for a variety of projects.

VIII. Conclusion

In conclusion, walkway gratings are critical elements in a wide array of projects. Their strength, durability, safety features, and versatility make them a preferred choice in numerous applications. Understanding their basics, features, selection criteria, and installation process is essential for anyone involved in their procurement, installation, or maintenance. As you embark on your next project, consider the valuable role these gratings can play in ensuring success.