Introduction

Have you ever wondered what 35 x 5mm galvanized steel grating is? This article will answer all your questions about this type of grating, exploring why it is popular, the applications where it excels, and much more. We’ll also provide facts and figures on the industry’s current state to give you an up-to-date overview of the topic.

35x5mm galvanized steel grating isn’t just material – it’s a solution! Discover how this product can solve your business challenges, provide up-to-date industry insights, and provide facts and figures to back it up!

1. Basics of 35 x 5mm galvanized steel grating

The 35 x 5mm galvanized steel grating is an incredibly versatile and durable construction material. Manufactured using the latest advancements in steel technology, this product is designed to provide years of reliable service.

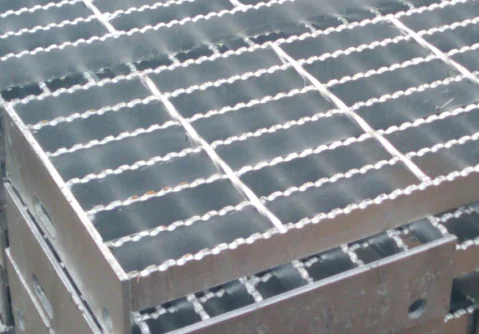

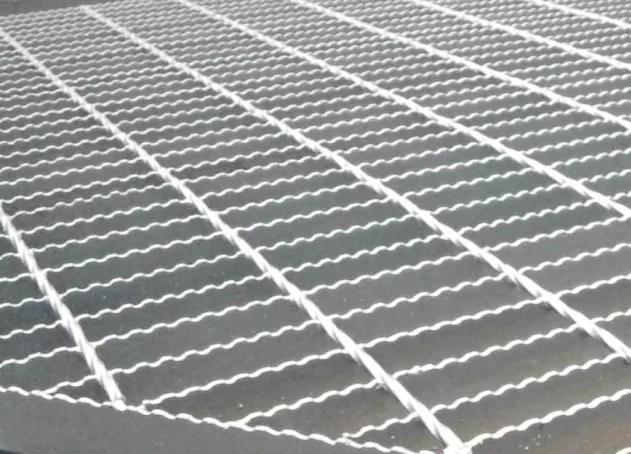

The galvanized coating further protects the bar grating from corrosion, ensuring superior performance in even the most extreme conditions. The 35 x 5mm grating features a series of cross bars welded at their intersections to bearing bars, creating a rigid and strong structure.

This unique design allows for greater strength than traditional flat bar grates, making it suitable for use in high-traffic areas such as stairways, walkways, and loading docks. Additionally, spacing between the bars offers superior drainage capabilities, allowing liquid or debris to flow freely without compromising structural integrity.

With its sophisticated construction and reinforced steel core, the 35 x 5mm galvanized steel grating is an ideal solution for any project that requires reliable support and long-lasting durability.

2. Different types of this steel grating

Several types of galvanized steel gratings can be divided into different styles, surface treatments, and materials. Some of the more common types include:

| Plain Steel Grating | This style is made of welded or riveted steel bars that are laid flat and form a grid pattern. The bars may be round, square, or rectangular. And its surface is flat. |

| Serrated Steel Grating | This style has serrated edges on the bars, which provide extra traction and safety. |

| Expanded Metal Grating | This style is made of metal that has been slit and stretched to create a diamond-shaped pattern. It is lightweight and economical. |

3. Benefits and applications of 35 x 5mm galvanized steel grating

Durable

It is designed to withstand heavy loads and harsh conditions, making it an ideal choice for various applications.

Corrosion Resistant

Another benefit of 35 x 5mm galvanized steel grating is that it is highly resistant to corrosion, suitable for marine environments.

Safe

The grating is slip-resistant and has a high level of traction, making it safe to walk on. Additionally, the grating is fire-resistant, making it an ideal choice for use in areas where fire safety is a concern.

Easy to Install

The modular design of the grating means that it can be installed quickly and easily without needing special tools or equipment. Check this article for a look!

Applications

The 35x5mm galvanized steel grating has many applications, particularly in the construction industry. Due to its inherent strength and durability, it can be used as a walkway, platform, or flooring material. This grating is made from high-quality galvanized steel, which offers superior resistance to corrosion and oxidation.

The grating is fabricated with close spacing between the bearing and transverse bars, ensuring a safe and secure walking surface for pedestrians. The open mesh configuration of this grating allows for quick drainage of liquids and debris off the surface, making it suitable for wet environments.

| Providing traction | Walkways and flooring solutions in areas with heavy industrial equipment |

| Galvanized | Applications in harsh industrial chemicals or extreme weather conditions |

| Lightweight | Quickly installed in any environment and easily maintained |

4. How long will it last

35x5mm Galvanized Steel Grating can last for a long time with proper maintenance and care, depending on the environment in which it is located. The galvanized coating provides added protection from rusting and corrosion, greatly increasing the longevity of the steel grating over time.

In outdoor locations with moderate exposure to moisture, galvanized steel grating could last up to 45 years or more. In more extreme conditions, such as coastal locations where there is saltwater exposure or places that experience snow and ice accumulation during winter, the life expectancy will be shorter due to the increased levels of corrosion caused by those elements.

To maximize the lifespan, it’s important to keep it clean and free of debris. Regularly inspecting it for signs of wear and tear is also beneficial, as this allows any potential problems to be spotted early on before they become major issues.

Conclusion

Regarding industrial production, 35x5mm galvanized steel grating is a must-have solution. This article will explain why and discuss its versatility, applications, facts, and figures from the current market. It’s essential reading for anyone looking to understand the power of this type of grating and how it can benefit you in your next project.