Introduction

Steel grating is an essential part of many industrial and commercial flooring applications. But which type of steel grating should you choose? Compare the advantages and disadvantages of plain steel grating versus serrated steel grating to find the best option for your needs.

Plain or Serrated Steel Grating? Both offer strong, durable, and slip-resistant surfaces, but the serrated design provides an added grip for extra safety.

1. Basics of two types of steel gratings

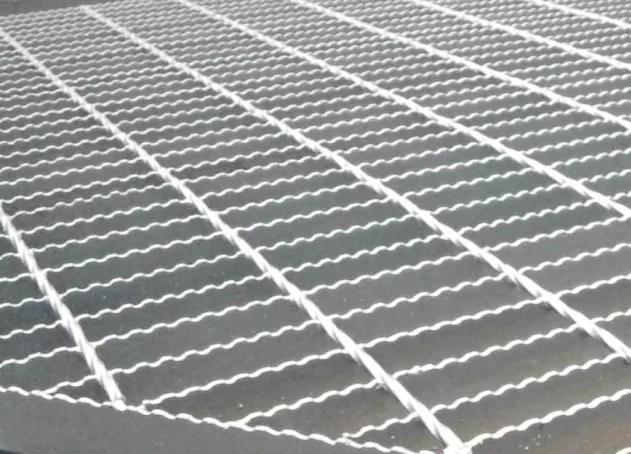

Plained steel grating

Plain steel grating is a type of metal grating that is manufactured using a variety of materials, including steel and aluminum, to provide a durable, slip-resistant surface. The grating is constructed with a series of interlocking metal bars that are connected by an array of cross bars.

The most common types of the grating are welded, press-locked, and riveted. Each type of grating has its unique characteristics and benefits. The bearing bars are available in a variety of sizes, thicknesses, and styles. The cross bars are usually welded at each intersection and are typically spaced at intervals of 4”, 6”, or 8”.

This type of grating is widely used in industrial, commercial, and residential applications. And also in architectural applications due to its aesthetically pleasing appearance. It is lightweight, which makes it a popular option for areas with limited space.

It is typically used in areas that require heavy-duty strength and durability, such as industrial platforms and walkways. This type of grating is also resistant to corrosion and can withstand extreme weather conditions.

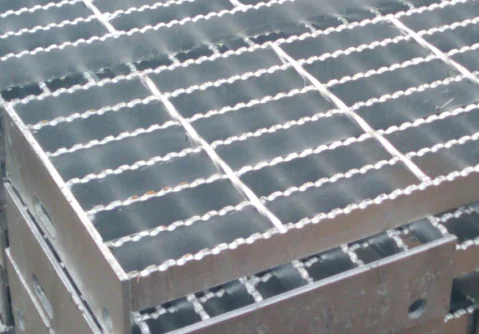

Serrated steel grating

Serrated steel grating is a reliable and cost-effective solution for a wide variety of applications. It is constructed from high-grade steel that has been cut into a series of parallel bars, with notches cut into the surface to form a serrated pattern. This pattern increases the structural strength and improves the traction of the grating.

It is available in a range of types and specifications, including welded, press-locked, swage locked, and riveted, and can be custom-manufactured to meet specific requirements. Serrated steel grating is an ideal choice for industrial applications such as stair treads, catwalks, platforms, and walkways, and can also be used in various residential and commercial settings.

Similarities of two types of gratings

- Both are made from steel, available in a wide variety of sizes and shapes

- Both can be used for a variety of industrial applications

- Both are slip-resistant, durable, and long-lasting

- Both are easy to install and maintain

- Both can provide good ventilation and drainage

- Both can provide adequate light transmission and visibility

2. Differences between two types of gratings

Anti-slip ability

In terms of anti-slip ability, plain steel grating has a smooth surface and does not provide as much traction as serrated steel grating. Serrated steel grating has a raised pattern that provides better traction and is better suited for applications where there is a risk of slipping or sliding.

Benefits

In terms of benefits, plain steel grating is more resistant to corrosion and is welcomed for its neat and clean appearance, making it a popular choice for applications where aesthetic appeal is important. Serrated steel grating, on the other hand, has a raised surface pattern that provides better traction and is better suited for applications where there is a risk of slipping or sliding.

Application

In terms of application, plain steel grating is commonly used in applications such as walkways, industrial sites, and stairways where aesthetic appeal is important. Serrated steel grating, on the other hand, is commonly used in areas with high traffic, such as loading docks and parking garages, as it provides better traction than painted steel grating.

Features

The front side of the serrated steel grating is serrated, which is an important safety feature for any walkway or stairs. The serrated surface helps to provide more traction, especially when the surface is wet. This can help to prevent people from slipping and falling when walking on it.

plain steel grating is flat on both sides, sometimes it doesn’t need to distinguish between the front and the backside. And it is used much more widely while its price is cheaper.

Conclusion

Plain steel grating offers a cost-effective solution for light loads, while serrated steel grating is more suitable for heavier loads and offers superior slip resistance, making it the superior choice in most applications.