Introduction

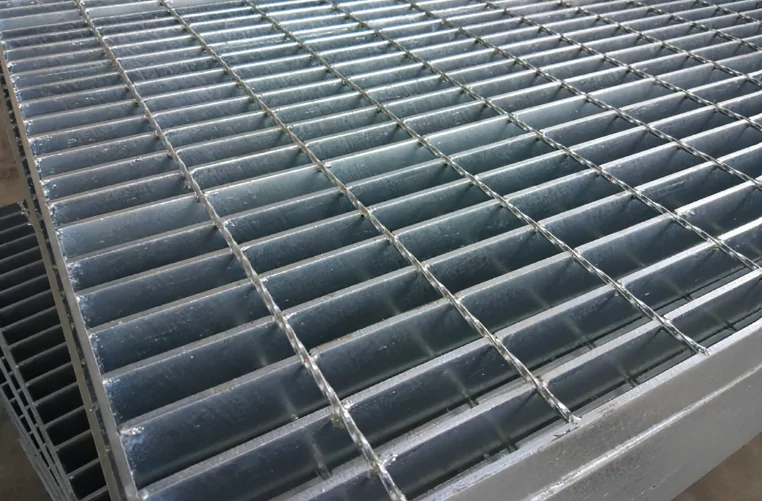

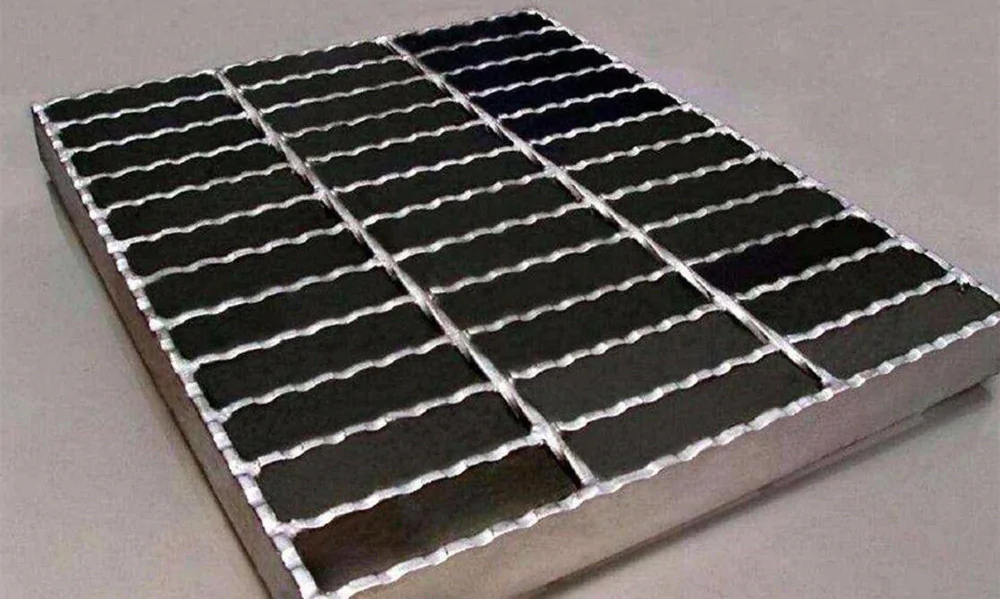

Steel Gratings provide protection, strength and character for industrial or architectural applications. It appears on catwalks, factory floors, platforms and in the railings and stairs. With its wide range of weight load capacities and surface types, locating suitable steel grating can be overwhelming.

Are you in the market for them but need help knowing where to begin? With this blog post guide, we will walk you through every step of the process so that getting pieces becomes straightforward-read on!

1. Measure items

1. Before getting a sample of a steel grating, it is crucial to determine the specific measurements that are required. This includes the length, width, depth, span and sizes of bars.

2. When starting measurement, be sure to get accurate measurements so that the gratings fit in their designated spots without needing extra material or modifications. The pitch is an essential part for this step because it determines how close together each bearing bars is connected with the other, while cross bars width will influence how much support and stability each bar grating product will provide.

3. For larger gratings, it may also be necessary to measure the depth and span of grating when it is placed hoizontally. The depth should refer to the height of grating, while the span refers to the length of grating as a whole.

Again, precision with these depth and span measurements can make all the difference regarding safety and aesthetics, so take care when taking them down!

2. Material requirements

| Stainless steel | One of the strongest types of gratings. It has high corrosion resistance and can be used indoors and outdoors, an excellent choice for areas exposed to salt or chemicals, like a chemical or industrial space. |

| Carbon steel | The most common type used widely in scaffolding. The original color is black without any treatment. Hot-dipped galvanizing or painting is adopted often for better performance. |

| Aluminum | A lightweight material perfect for outdoor applications where weight is an issue (such as balconies). Excellent corrosion resistance makes it ideal for coastal areas or where water exposure is likely (like pools). |

| Fiberglass | A composition of fiberglass-reinforced plastic. Fiberglass bar grating is frequently used where weight is required to be reduced, such as on high-rise buildings where vast amounts of equipment must be installed swiftly and ensure safety. |

3. Surface treatment

Hot-dipped galvanizing

Features an attractive appearance, acid and alkali resistance, corrosion resistance, and rust resistance, and it has a long service life span, suitable for outdoor applications.

Cold-dipped galvanizing

Suitable for dry environments, such as indoor applications. If used outdoors, in cold or damp environments, it only lasts about 3 or 4 months to get rust.

Painting

Corrosion resistance at a medium level, moderate price, optional color. It costs lower than the galvanized one. When steel gratings are used for machine equipment, it is often painted in the same color as the equipment, like grey or black.

Untreated

Cheap, suitable for indoor and dry environments, but quickly gets rusted in wet and rainy environments.

4. Find suppliers and show your hand

Finding the best supplier for steel grating is essential for any project that requires this specialty product. Researching different vendors to compare prices and quality is a great way to ensure you get good value for your money.

You can find suppliers by physical location or look online, where many vendors specialize in steel grating products. Once you’ve found potential suppliers, you must read customer reviews before purchasing from them. These will provide an honest account of the suppliers’ level of service and the quality of materials they provide.

Finally, ask questions like what kinds of warranties they offer or their returns policy, just in case anything goes wrong. With a bit of research and due diligence, you can easily find a reliable supplier!

To conclude

- Search online, from Google/LinkedIn/trade directory/international trade online platform.

- Contact suppliers and tell them your intentions

- What you need (specifications)

- Expected lead time, price, terms of payment, validation, package, transportation, etc.

5. Manufacture steel grating samples

Manufacturing steel grating samples is a critical process in producing steel grating products. Sophisticated production procedures are implemented to fulfill product specifications and quality standards.

Confirm all your requirements with the supplier. After cutting, welding, banding and surface treatment, manufacturers can provide products with superior construction for toughness and durability even when exposed to harsh elements or highly-trafficked areas.

6. Package and transportation

An improperly packaged steel grating sample can lead to damage, making your project more difficult or impossible. Here are some tips on how to package a steel grating sample:

| Bundling | The most common method. This involves using straps or bands to tightly secure the steel gratings together in a neat and flat stack. |

| Screw Rod Fixation | By placing four screws through the aperture of each of the individual gratings before securely fastening them together with nuts or washers, this method provides an even greater level of security than bundling alone. |

| Pallet Packaging | For long-distance travel or export purposes. Two main pallets are used for this purpose: wooden pallets and metal pallets, depending on the size and shape of your particular gratings. |

| Proper Labelling | clearly label all boxes containing your steel gratings before shipping them off to clarify what’s inside once they reach their destination |

Also look into professional freight companies with experience in shipping materials like these, and they will take extra care with your shipment from origin to destination point.

7. Receive and check

1. When receiving a steel grating sample, check the quality before installation. Inspect all grating surfaces for any damage or signs of wear and tear. Ensure that there are no sharp edges, irregularities, or surface defects on the product, as these could affect its safety, strength and durability.

2. Check that the grating is made from high-quality grade steel and not a lower grade, such as zinc-plated steel, which could rust over time.

3. Measure each length, width, and height to ensure that it meets the specifications. If you find any discrepancies in size or shape, contact your supplier immediately to replace or repair the product as needed.

4. Assess whether enough holes are drilled into each panel for anchoring purposes. So you can safely secure it onto a platform, floor or wall without compromising its structural integrity over time with added stress from anchors, shifting out of place due to weight-bearing bars down on them from above or below ground level movements.

5. Observe how easily panels fit together when connecting them with clips, bolts, clamps, etc., as this will determine how quickly and efficiently you can install an entire section of grating at once versus having to individually connect each panel one by one with tools like wrenches or pliers.

Conclusion

No matter what industry you’re in, gathering information and platforms to decide can be daunting. We hope that this quick run-through of the process for ordering a steel grating sample helps streamline things for you so that you can confidently move forward with your project, knowing that you’re making the best possible decisions.