Introduction

Looking for different shapes of steel gratings according to their applications? Look no further than this article! You may pick from a number of steel gratings on this list that are ideal for a wide range of applications and can be customized to match your unique demands.

Steel grates come in all shapes and sizes, each one serving a unique purpose. From metal grating to bar grating, there’s a steel grate for every need.

These steel grating shapes may be used for small holes, coverings, manufacturing platforms, fountains, walkways, floors, tanks, and many more applications.

If you’re interested to discover every shape of steel gratings to check whether it will fit your needs, continue reading to know more.

What is a Steel Grating

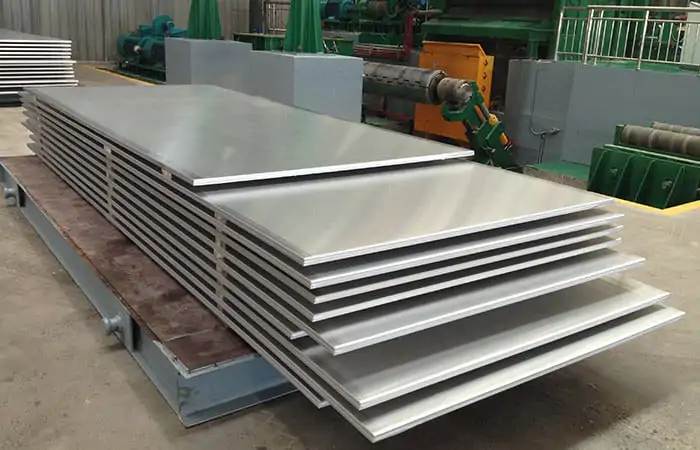

Metal grating is an open lattice structure made of metal rods that are both strong and light. The spaces between the bars allow for enormous loads to be carried while minimizing weight.

A metal grate is made out of steel and is used in construction to hold back sand, water, or other materials.

It can also be used in engineering to support heavy objects such as vehicles or machinery. It can be found in everything from parking lots and sidewalks to roofing materials. The grid’s metal bars are separated by either rigid attachment to cross bars or bent connecting bars.

The biggest advantage of using metal grating is its ability to withstand heavy loads while remaining lightweight and easy to transport. It’s great for use in applications where weight is an issue, like building bridges or military armor, but it also performs well in situations where there’s a lot of weight being put on it, like water filtration systems or construction sites.

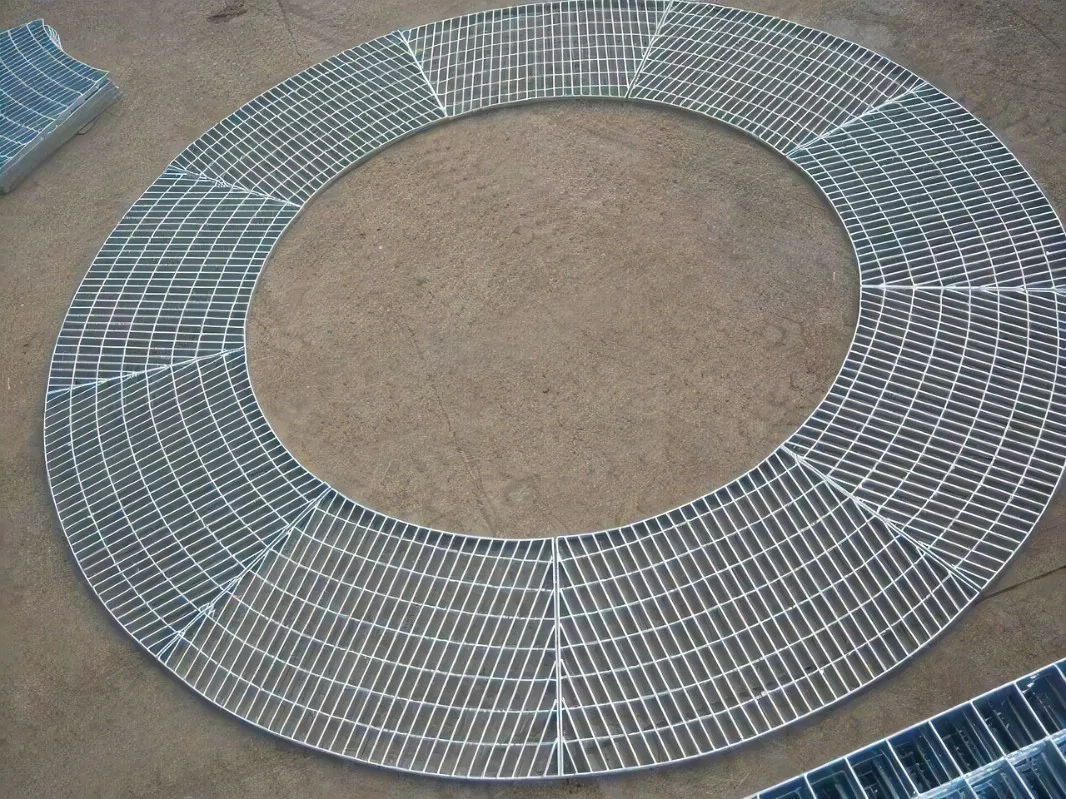

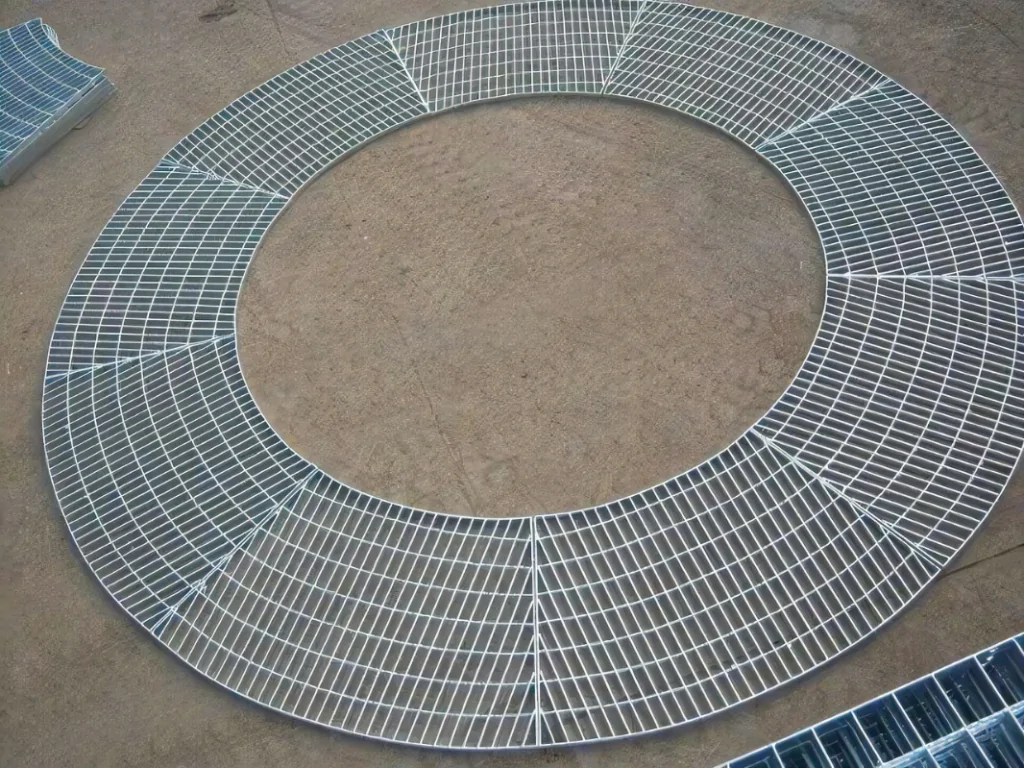

The Different Shapes of Steel Gratings

Here are the different shapes of steel gratings:

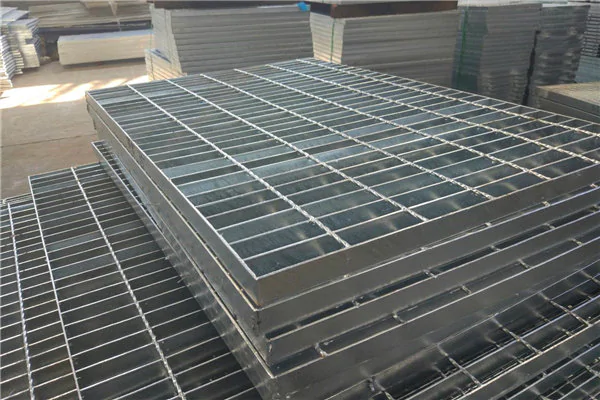

Bar metal gratings

The most common sort of steel grating that people think of when they hear the term “metal grating” is bar grating. They are suitable for use in the construction and industrial industries as well as other applications where protection from falling debris is required.

A bar metal grate provides the highest level of security while still allowing easy access for authorized personnel. Its modular design makes it ideal for both indoor and outdoor use, and it can be easily incorporated into existing systems with minimal effort.

Compound metal gratings

A compound metal grate is a type of heat exchanger that uses alternating layers of different metals to transfer heat efficiently across a wide range of temperatures.

In general, the denser metal will be on the outside and the more diffuse metal will be on the inside; this keeps them separated so they don’t mix or corrode.

The shape of a compound metal grating is according to the number of lines per inch. The grating has three different shapes depending on how many lines there are per inch: 3 lines per inch, 5 lines per inch, and 7 lines per inch.

The more lines there are in an area, the more effective it will be at blocking that type of radiation.

For example, if an area needs protection from both X-rays and gamma rays then the 5-line would be best because it provides protection against both types of radiation while the other two only protect against one or the other (depending on whether it’s an X-ray or gamma ray).

Expanded metal gratings

The expanded metal gratings that are made of parallel metal bars that have been connected apart from one another have variations of square, hexagonal, and triangular shapes depending on the applications. Expanded metal grating is used to protect surfaces from liquids or objects while allowing for simple airflow.

As a result, gaps appear between the bars.

An extended metal grating’s dimensions are determined by the shape that it is intended to have. The following are some examples:

- A rectangular shape has dimensions of 5cm by 7cm.

- A square shape has dimensions of 2cm by 2cm.

- An oval shape has dimensions of 4cm by 1cm.

- An octagonal shape has dimensions of 3cm by 3cm.

The purpose of an expanded metal grating is to provide protection from physical attack or fire. They are made with a series of holes along the surface which create open spaces between the wires. These open spaces allow fluids or gases to pass through easily but make it difficult for solids to get through.

This makes them useful as filtration systems in things like water treatment plants or chemical factories that handle hazardous materials.

They are also widely used in the military because they offer protection from bullets and shrapnel while allowing air to pass through easily so soldiers can breathe easily even when there’s heavy smoke in the area!

Swaged Metal Gratings

The shape of a swaged metal gratings is determined by the shape of the forging die that made it. This allows for making a great variety of swages with different geometries. The most common shapes are round, square, and rectangular but we can also make other shapes like triangular or oval if needed.

It used high-quality materials like stainless steel and aluminum because they’re strong and durable, not easy to break like other materials would be.

Dove-Tailed Metal Gratings

This metal grating is divided into small squares with space between them. This metal grating is divided into small squares with space between them. It can be made in different shapes, including square, rectangular, triangular, trapezoidal, or any combination thereof.

Welded Metal Gratings

The shape of this grating is based on a square or rectangle with rounded corners. The angle at which the bars are placed can be varied depending on what application you’re using it for.

For example, if you want more surface area to push against than water would provide then you would want a greater angle. If you wanted to push against water then you would need a lower angle so that it could hold its shape better.

Riveted Metal Gratings

The shape of a riveted metal grate depends on the size of the holes in it. Smaller holes have sharper edges, while larger holes are more round. The size of the hole also determines how much water will flow through it: smaller holes let less water through than larger ones.

This metal gratings shape has dimensions 2x1x0.25 inches with a thickness of 0.03 inches and it is made of steel. It has four different sizes available: small (3×1), medium (2×2), large (1×3), and extra large (3×3).

The shape of this metal grating is based on the size of the holes in it. The hole sizes are typically listed as an inner diameter followed by an outer diameter separated by a dash, like [10-12]. This means that there will be 10mm wide holes spaced 12mm apart from each other.

Perforated metal gratings

A perforated metal grating is made by the form and mount of the holes punched onto the bar gratings that will determine its shape. These perforations can be circular or square, depending on what application the grating is being used for.

The most common sizes are 6mm by 6mm (1/4 inch by 1/4 inch), 8mm by 8mm (5/16 inch by 5/16 inch), 10mm by 10mm (3/8 inch by 3/8 inch), and 12mm by 12mm (1/2 inch by 1/2 inch).

The shapes of these perforations determine how much light passes through them – so if you want more or less light to pass through your grating then choose one with larger or smaller perforations!

Press locked metal gratings

The shape of press-locked metal gratings is determined by two factors: the dimensions of the mesh, and the width of the material used to make the grating. The general rule for determining the dimensions of a press-locked metal grate is that it should be one inch larger than its intended use.

For example, if you want a press-locked metal grate that’s meant to protect children from falling into your pool then it needs to have an opening width of 6 inches, and a height and length that are both 7 inches.

If you want a press-locked metal grate that’s meant to protect adults from being kicked in the head by soccer balls then it needs to have an opening width of 5 inches, and a height and length that are both 6 inches.

Safety gratings

This strip grut grating form is created by slicing the metal into lengthy strips. These strips are then bent into different shapes using machines called press brakes or bending mills. The process is similar to making jewelry; it requires great attention to detail and precision along with strong metalworking skills.

Wire mesh metal grating

The wire mesh metal grating shapes are determined by how the rows and columns of the bar grating are organized and formed. The wire fabric or cloth wire is welded or woven depending on the manufacturer as the columns and rows are connected with welded wire metal grating that passes over and under at their connecting points.

The Benefits of Each Shape

Here are the benefits of each shape in every application:

Bar metal gratings

Floor metal grating is formed from bar metal grating, which is often made of steel or aluminum and has a good strength-to-weight ratio.

Compound metal gratings

It is non-slip, anti-corrosion, has an excellent drainage function, does not gather dust easily, and is simple to install and maintain.

Expanded metal gratings

The benefit of an expanded metal grating is that it is used to flatten the surface which will give a uniform and smooth finish when applied.

Swaged Metal Gratings

The main benefit of using swaged metal gratings is for design and strength purposes of the surface once applied.

Dove-Tailed Metal Gratings

As a result, the surface is level, homogeneous, firmly locked, and stiff.

Welded Metal Gratings

Welded metal gratings can give you the benefit of a strong bond that will a long-lasting service depending on the application used.

Riveted Metal Gratings

Riveted metal gratings are made to have features as more resilient to impact applicable to heavy loads. This grating has the ability to resist the strain and stress coming from the cross bars which will serve as a strong characteristic and attribute to the whole bar grating itself.

Perforated metal gratings

Perforated metal gratings can give benefits to an area that are meant to be not penetrable by a sound, good ventilation that can give the space moving air, especially for crowded rooms, and shield or guard the surface, particularly in the certain area where it is applied.

Press locked metal gratings

The visual quality of press-locked metal gratings fits well with complementing styles and designs. Its high bearing capacity is combined with a low specific quantity of steel which applies to large and open operating places. It has easy fabrications that are easy to install.

Safety gratings

A benefit of using safety gratings as its name literally says its purpose is to have a grip that is made by a stamped material serration on every edge of the grating.

Wire mesh metal grating

Wire mesh metal grating is used for its ability to adapt and diverse features. It is incredibly easy to install and has applications in many different industries.

How Each Shape can be Used in Various Applications

Press locked or welded gratings for platforms

Platform grating, which is made up of many pieces of press-locked or welded stainless steel grating, is frequently installed in ships and other industrial settings such as offshore platforms, power plants, and refineries.

Steel gratings on floors

Steel grating flooring features an anti-slip surface, high load-bearing capacity, effective drainage, and corrosion resistance. As a result, it is frequently utilized in factories, parking lots, bridges, viewing platforms, parks, and gardens.

Steel gratings in stairs and bridges

Steel grating can be used as a bridge deck due to its properties such as resistance to corrosion, non-slip, durability, high load-carrying capacity, and lack of trembling. It is made to have different bridge decks, including suspension bridge decks, footbridge decks, and walkways that enable people to cross wetlands, valleys, creeks, and other terrain types.

Metal gratings in buildings

If you’re into designs and styles and you want a building or structure feature that compliments the whole area, metal gratings offer a different appeal that will benefit the aesthetic appearance of the surroundings.

The surface types can be plain grating or serrated grating. Custom designs like a cutout, toe plate, and stair treads are applicable. Steel grating as ventilation can be used as ventilated steel metal grating can be used as a building facade.

Gratings in filtration systems

One of the main features to look out when you’re looking for the perfect shape of the steel gratings is its ability to have the long-lasting capacity to provide certain uses. Just like water filtration systems they need to have an anti-corrosion ability to adapt to their environment that guarantees the benefit in the long run.

Floor metal gratings

Metal grating is most commonly used when it comes to flooring applications just like in roadways and walkways. The material should be able to withstand the weight of the people and vehicles that will move along the way.

Fencing with metal gratings

The ultimate goal of having a fence is to provide secure protection to an establishment owner. The metal gratings as its main material have a strong and firm installation together with being pleasing to the exterior appearance of the fence itself.

Common Materials for Irregular Steel Gratings

Here is the common material for irregular steel gratings that you should look out for when it comes to differentiating the shapes of steel gratings according to their applications:

Aluminum

Aluminum metal gratings have high thermal and electrical conductivity, are malleable, ductile, and corrosion-resistant. It is non-toxic, non-magnetic, lightweight, and resistant to bacterial development.

Light Duty Steel Metal

An irregular steel grating that is made with carbon steel or light-duty steel metal and can be made on an open grid structure with perpendicular load bearing bars as proportioned to have a quality steel grating.

Stainless Steel

Metal grating comes in a variety of stainless steel materials that is made utilizing a variety of bar sizes and swage or welding procedures.

Galvanized Steel

The metal grating can also be made using galvanized steel that has zinc as its coating to its carbon steel.

Heavy-Duty Carbon Steel

As the term heavy duty itself, metal gratings that are made with heavy-duty carbon steel are made to have a thicker steel bar that are paired with welded materials to be connected to withstand dense and large loads that will have the benefits of long-lasting service life.

Conclusion

In being curious about the different shapes of steel gratings or metal gratings in every application that will fit your needs, I hope this article gave you an insight into how it is made and formed according to the details included in this informative composition of the necessary details regarding the steel gratings that you want to avail in the near future.