Introduction

Do you know what the pipeline steel grating floor is? If you’re an engineer, professional, or construction worker, you should.

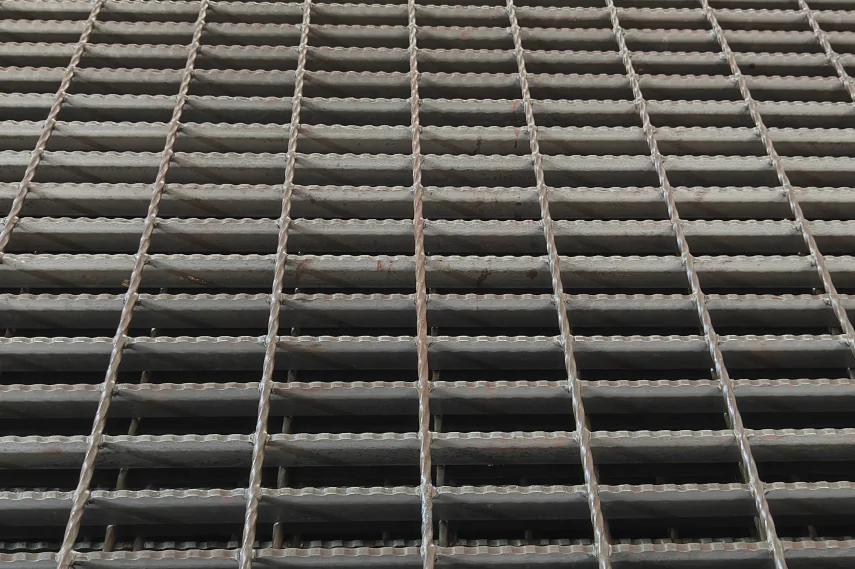

Pipeline steel grating floor is a popular choice for heavy industrial and commercial settings. It is a type of metal grating designed specifically for pipeline use. Its robust construction and anti-slip surface makes it ideal for use in areas where safety is a concern.

The pipeline gallery is a corridor of pipes. In chemical and related factories, pipes are clustered and arranged along the outside of the plant or building, usually held up by brackets in the air. To facilitate workers’ walkway walking around the pipes, steel grating is adopted to pave floors.

But what exactly is pipeline steel grating floor, and what are its benefits? In this article, we’ll look at what makes pipeline steel grating unique and explore ways it can improve your workplace or facility. Let’s get started!

1. What is a pipeline steel grating floor

Pipeline steel grating floors are flooring systems commonly used for walkways in industrial applications. They provide excellent support and durability due to materials such as carbon steel, aluminum, and stainless steel. This is characterized by its loose planks, which allow air and liquids to pass through while still being strong enough to bear heavy loads.

2. The benefits of pipeline steel grating flooring

| 1. Safety | The grating comprises a series of closely spaced bars that are welded or pressed-locked together. This design helps to create a robust structure to help prevent accidents from falling. |

| 2. Low maintenance | The close spacing of the bars prevents dirt or debris from accumulating on the surface, making it easy to clean with a broom or hose. Also, it is resistant to damage from chemicals and other harsh cleaning agents. |

| 3. Improved aesthetics | The close spacing of the bars creates a sleek, modern look that can help to make a space look more professional and polished. Additionally, being available in various colors and finishes, allowing it to be customized to match the décor of any setting. |

| 4. Durability | It will not get warped and cracks easily and not need to be replaced as often as other types of flooring. The grating is designed to withstand heavy foot traffic and can last many years with proper care and maintenance. |

| 5. Easy installation | The individual bars are typically pre-cut and ready to be installed, no need for special tools or equipment. It can also be easily cut to fit any space for new construction and renovation projects. |

3. Where pipeline steel grating flooring can be used

The pipeline steel grating on the pipe frame is a walkway and climbing operation platform on the site. Its application is simple, though some adjustments may be needed for your specific needs depending on what you want it to do best.

The primary purpose of these gratings in between each supporting beam during the loading process is that people can safely reach their destination without getting into any danger while also ensuring stability by making sure no one side topples over onto another due to weighty objects being placed atop them.

4. How pipeline steel grating floor is installed

Hoist gratings to the right place

The steel gratings on each floor platform close to the scaffold operating platform shall be hoisted into place as a single piece and installed by qualified installation employees on the forum. Temporary fastening must be completed to provide protection (baseboards, temporary railings, stairs, bridges, etc.).

Adapt the scaffolds

Hoist the entire bundle of steel gratings onto the platform, where the operators will unpack the bundle and extend each grating to the surrounding area. Simultaneously, the scaffolding worker must collaborate with the steel grating laying people to adapt the scaffolds to the steel grating laying’s specifications.

Weld the connections

Remove the zinc coating or painted part, rust, oil, and water from the bearing bars and cross bars surface before welding. Then start welding.

Final inspection

Remove the slag or the splash from the welding surface and inspect the features of the seam’s aesthetic quality. Check the state of the welds again, section by section, and conduct an inspection.

5. How to clean and maintain pipeline steel grating floor

- Inspect the grating regularly. It would be best if you inspected your pipeline steel grating floor regularly for any damage or debris that could cause problems. If you see any damage, repair it immediately to prevent further damage or injury.

- Sweep the floor regularly. Sweep the floor of your pipeline steel grating regularly to remove any dirt, dust, or debris that could cause problems.

- Use a mild cleaner on the floor. Use a mild cleaner to avoid damaging the surface of gratings, like zinc coating or painting layer.

- Rinse the floor after cleaning. After cleaning, you should rinse it with clean water to remove any residue from the cleaner. This will help to prevent slip hazards and keep your floor looking its best.

Conclusion

A pipeline steel grating floor is a series of triangulated, closely spaced bars affixed to bearing bars and shaped according to the intended use. It is widely used in industrial factories, which usually carry heavy materials or large and medium-sized mechanical equipment.

The advantages of this product are apparent: it has high strength and load capacity, excellent precision, stable quality, bright surface appearance, safe and comfortable to walk on, easy installation, etc. These features make it a popular solution for pipeline floors in industry.