Introduction

If you’re looking for a strong and reliable metal grating solution, take a closer look at the I-Bar steel grating. This durable and versatile material is ideal for a range of applications in both industrial and commercial settings.

The I-Bar Steel Grating is an innovative product that has revolutionized the construction industry. Take a closer look at how it can revolutionize your project!

1. Basics of I-Bar Steel Grating

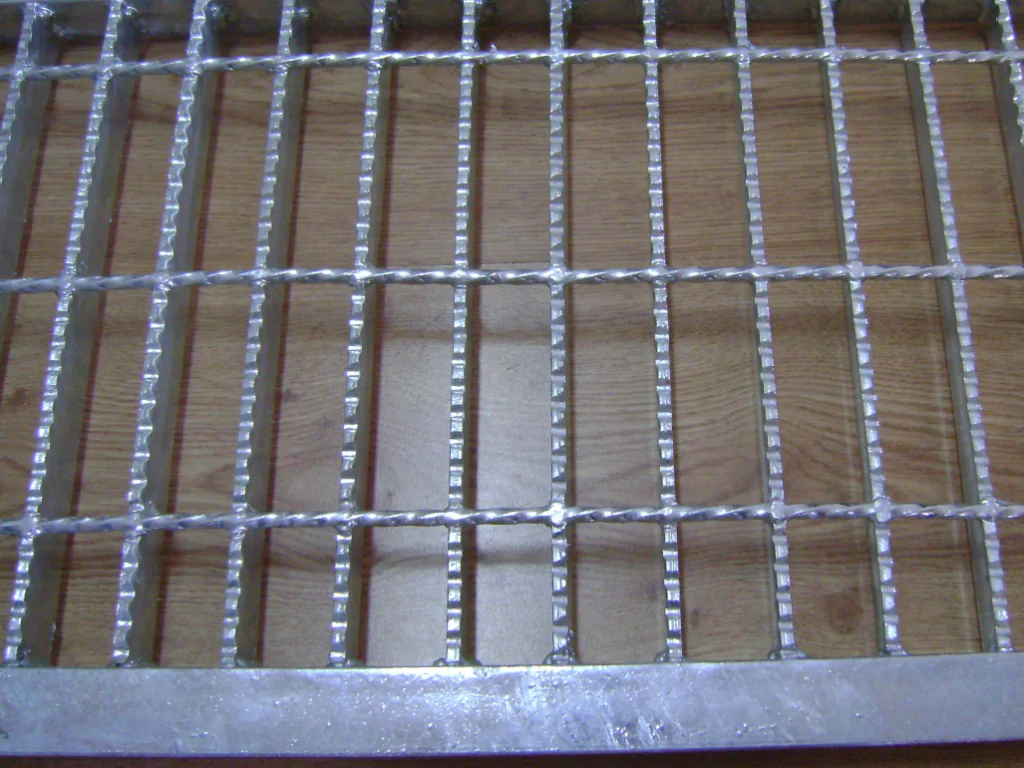

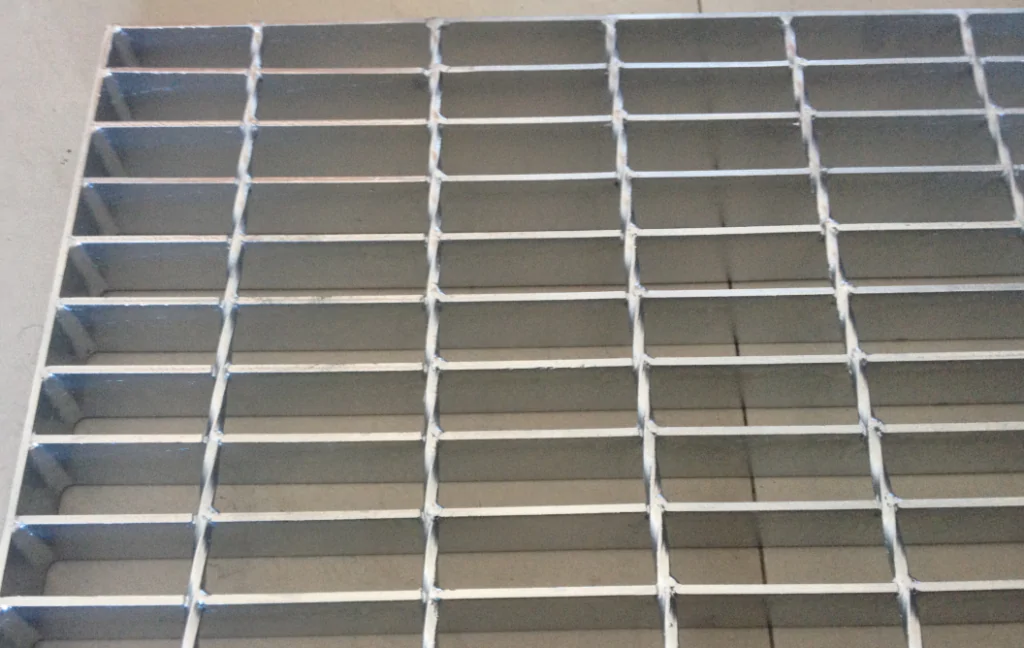

I-bar steel grating is a type of steel grating with a crossbar at the center of each bearing bar. It is a cost-effective solution for many applications, such as flooring, walkways, security, and drainage. The crossbar helps to increase the rigidity of the steel grating, and also provides an aesthetically pleasing, architecturally appealing look.

2. Types of I-bar steel grating

Material

- Mild Steel, Stainless Steel

Mild steel and stainless steel are two of the most popular materials used to make I-bar steel grating. Mild steel is a strong, durable material that is used for a variety of applications, including structural support, industrial equipment, and outdoor structures.

It is also relatively inexpensive and easy to work with. Mild steel I-bar steel grating is often used for outdoor structures and in industrial applications where strength and durability are important.

Stainless steel is an alloy of iron and chromium, which is resistant to corrosion and rust. It is an ideal material for use in outdoor environments, where it is exposed to the elements.

Stainless steel I-bar steel grating is often used in marine and coastal applications, as well as in food processing facilities. It is also used in applications where hygiene and sanitation are important, such as medical and laboratory facilities. Stainless steel is more expensive than mild steel, but it is also more durable and resistant to corrosion.

Surface

- Electro-Galvanized, Hot Dipped Galvanized, Powder Coated

Electro-galvanized steel grating is created by running plain steel grating through an electro-galvanizing process which coats the steel with zinc. The zinc protects the steel from corrosion and provides a long-lasting, maintenance-free finish.

The zinc coating also gives the steel a bright, shiny appearance. This type of steel grating is commonly used in outdoor applications due to its superior corrosion resistance.

Hot-dipped galvanized steel grating is manufactured by dipping plain steel grating into a bath of hot molten zinc. The zinc coating provides a protective layer that will rust-proof the steel for extended periods, even in the harshest environments.

Hot-dipped galvanized steel grating is ideal for applications that require a long-lasting, corrosion-resistant finish. Powder-coated steel grating is created by applying a layer of powder coating to plain steel grating. The powder coating is applied electrostatically and then cured under heat to form a protective layer that is tougher than conventional paint.

Powder coating is available in a wide range of colors and is commonly used in architectural and industrial applications. Powder-coated steel grating is extremely durable and resistant to corrosion, making it an ideal choice for outdoor applications.

Specification

- Heavy Duty, Light Duty, Standard Duty

Heavy-duty I-bar steel grating has a thicker, heavier bar and is designed to handle heavier loads. It is often used in industrial and manufacturing applications where the grating must support heavy machinery or equipment, such as forklifts.

Light-duty I-bar steel grating has a thinner, lighter bar and is designed for use in lighter applications, such as walkways and stairways. It is usually not suitable for industrial or manufacturing applications.

Standard duty I-bar steel grating is designed to handle moderate loads and is often used in applications such as mezzanines, platforms, and catwalks. It is a good choice for applications that require a balance between strength and cost.

3. Benefits and application

Industrial Platforms and Walkways

I-bar steel grating is ideal for creating industrial platforms, walkways, and catwalks due to its superior load-bearing capacity and strength. Its open design provides a safe, anti-slip surface that allows for good drainage and is easy to clean.

Drainage Systems

I-bar steel grating can be used to create a drainage system that is not only strong but also aesthetically pleasing. Its open design allows for easy water drainage and can be used for both indoor and outdoor applications.

Safety Fences

I-bar steel grating can be used to create a secure, anti-climb fence that is both aesthetically pleasing and effective. Its open design allows for great visibility and is ideal for use in industrial and commercial settings.

Mezzanines and Racks

I-bar steel grating is ideal for creating mezzanines, rack systems, and shelving units due to its load-bearing capacity and strength. Its open design allows for the flow of air and light and provides a safe, anti-slip surface that is easy to clean.

Staircases and Ladders

I-bar steel grating is commonly used in staircases and ladders for its superior strength and durability. The grating can be used in both indoor and outdoor applications, providing a solid footing and support.

Machine Guards

I-bar steel grating can be used to create machine guards to protect workers from moving machinery and parts. The grating is strong enough to withstand high impacts, making it an ideal choice for industrial applications.

Wheelchair Ramps

I-bar steel grating can be used to create wheelchair ramps that are strong and durable. The grating provides a safe and secure surface for wheelchair users, allowing them to maneuver around easily.

Decking

I-bar steel grating can be used for the construction of decks due to its high load capacity, corrosion resistance, and slip resistance.

4. How to choose the right type

Consider the load requirements and the size of the area where the grating will be used to choose the appropriate size and shape of the grating. The size and shape of the grating should be based on the load requirements and the size of the area where the grating will be used.

The size should be determined by the size of the area, the type of load that will be placed on the grating, and the size of the grating required to support the load. The shape should be determined by the area where the grating will be used, the load requirements, and the design of the grating.

Choose the material of the grating

I-bar steel grating is a popular choice for many projects due to its durability and strength. When selecting the material for an I-bar steel grating, it is important to consider the intended application and environment. Other factors to consider when selecting material for an I-bar steel grating include cost, installation requirements, and aesthetics.

Select the bearing bar size

The size of the bearing bars will depend on the load requirements of the project. When selecting the bearing bar size for an I-bar steel grating, it is important to consider the application of the grating.

In addition, the size of the bearing bar should also be determined by the desired opening size of the grating. If a larger opening size is desired, then a larger bearing bar size would be necessary.

Another important consideration when selecting the bearing bar size is the overall strength of the grating. Generally, larger bearing bar sizes provide increased strength for the grating. However, this must be balanced with the need to provide an open area for the application.

Finally, the bearing bar size should also be chosen based on the environment in which the grating will be installed. For areas with heavier loads or harsher conditions, a larger bearing bar size may be necessary to ensure the longevity of the grating.

Choose the type of finish

When choosing I-bar steel grating, the type of finish applied to the grating is an important consideration. Depending on the intended application, the finish should be selected based on factors such as corrosion resistance, performance, aesthetics, and cost. I-bar steel grating can be finished with a galvanized coating or a powder coating to protect it from corrosion.

The most commonly used finishes for I-bar steel grating are galvanizing and powder-coating. Galvanizing is the most economical option and is great for outdoor applications while powder coating can be used for applications that require additional abrasion resistance and strength.

Conclusion

The I-bar Steel Grating is a versatile and durable solution for various applications. With its superior strength and corrosion resistance, it can withstand harsh weather conditions and provide a safe and secure walking surface.