Various structures around us are constructed using different materials; among many of them, you have also come across steel gratings too.

These steel gratings serve multiple purposes and offer strength to the structure, but there is a lot of detail about them that one must be aware of.

Steel grating proves to be a very strong structure used for security purposes and offers a platform to handle heavy loads.

Apart from this stair treads, fences, and even the ventilation closures are made out of steel gratings.

Steel gratings are even used for pedestrian bridges, and you will get an insight into many more things about these after going through this guide.

Now, you must be excited to learn about welded wire metal grating, so let’s read. By this guide’s end, you will have learned almost every detail about steel grating. So let’s walk through this guide below.

What Is Steel Grating?

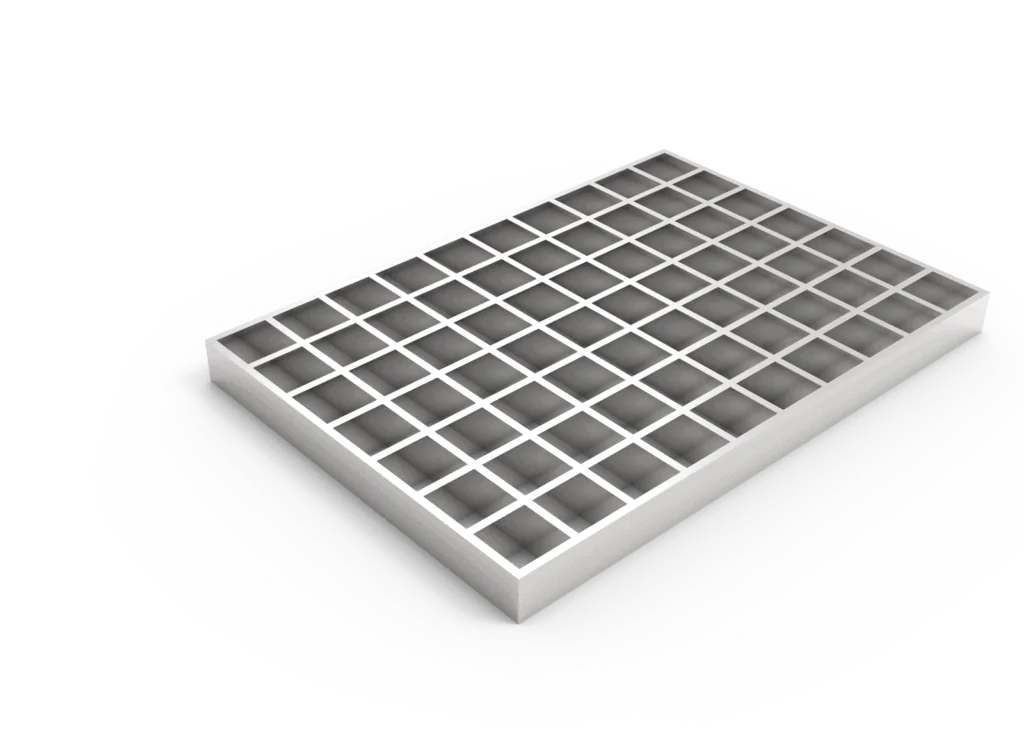

One of the first questions that might click your mind when you hear the word “Steel Grating” would be what it is. Bar grating is a grid.

It is made of steel bars that run horizontally and vertically, and the edges are finished with a steel frame.

This grid-like structure comprises bearing bars and cross bars placed perpendicular to each other to create a grid-like structure.

This structure is seen in many instances and is usually used to handle the heavy load. The steel grating itself is very light, but at the same time, it can handle heavy weight.

Stair treads, mezzanines, platforms at the factories, drainage covers, floors, and fences are usually made using these gratings.

Types of Bar Grating

There is no one kind of steel grating that could universally be used for all applications. There is a wide variety of expanded metal grating.

It differs in terms of the finishing, the layout, the purpose it is meant to be used for, and much more. Let’sLet’s read below and learn about these different types.

Galvanized Steel Grating

Galvanized bar grating is finished with a shiny surface and offers corrosion resistance properties.

So areas where a expanded metal grating that doesn’t corrode is needed, galvanized grating goes the best. It is most commonly used in sewage treatments, and power plants as these are subjected to a lot of moisture.

Welded Steel Grating

The bars are welded together using intense pressure and heat in a welded Steel bar grating.

This leads to a very strength-oriented form of expanded metal grating suitable for use in environments where pressure is exerted. Heavy loads are handled perfectly when it comes to welded steel gratings.

Press Locked Steel Grating

The steel bars are very closely fitted together in a press-locked bar grating using the hydraulic press technique.

This creates a net-like structure with significantly less space between the bars. These are commonly used in ventilation grates, sunshades, etc.

Plain Steel Grating

Plain Steel bar grating combines bearing and cross bars with no pointed edges and a flat surface finish commonly observed in various industrial applications.

Serrated Steel Grating

Serrated bar grating is a Floor Metal Grating that has a little bumpy kind of surface.

This surface is suitable for where one needs slip resistance to prevail and is commonly used in stair treads and walkways to avoid slipping in such areas.

Heavy Duty Steel Grating

The heavy-dutysteel bar metal grating, as the name suggests, is used at the place where heavy loads need to be lifted.

The heavy-duty bar grating is known for its excellent strength-to-weight ratio and is usually observed in applications where forklift trucks are used to lift heavy loads.

Advantages of Steel Gratings

If you look around, you will come across various places and applications where steel gratings are commonly found for different reasons.

The concept of using steel bar metal grating is not new and has been in place for a long time, there are many benefits of having these, and some are discussed below:

Provides for Safety

In areas where slip resistance is needed, stainless steel grating can be used. In such cases, the use of serrated steel gratings is common as the rough surface has helped in resisting slipping.

Apart from this, a stainless steel grating grating is also used in place of an opening as it provides coverage and doesn’t let anyone enter the space. It could be a safety measure for various windows and open passages.

It also helps in load management; industries where heavy loads are required to be kept, prefer having platforms made using stainless steel grating as they can handle the weight of those loads and offers a safe means of storage.

Provides For Ventilation

Commercial and industrial spaces require appropriate ventilation, and the role played by steel grating in this regard is a common one.

The stainless steel grating is placed on the opening where the ventilation is needed, and it covers the open spaces and, at the same time, lets the air pass in and out.

In drainage systems, steel grating also carries out the same purpose for ventilation. It offers a safety measure by covering the drain’s opening and allowing ventilation.

Adds Durability and Strength to the Platforms

Steel is known for its strong properties; hence, the structures and platforms created without any predetermined foundation might be supported by steel gratings.

Many industrial workplaces have separate areas connected using steel grating stair treads and platforms. These platforms are durable with these bar metal grating so that people who work over them feel safe. These platforms also allow a separate working area.

Factors Affecting the Cost of Steel Grating

If you think all kinds of steel metal floor grating styles will be offered at the same price, you are wrong.

Various factors have an impact on the price of steel grating. Some of these factors that impact the price of steel grating comprise the following:

Cost of Raw Material

The cost of raw material, which is stainless steel grating, is one of the main determinants that affect the price of steel grating.

The price of steel fluctuates depending on demand and supply. So, when the cost of steel changes, it is quite eminent that the price of the steel grating will also change.

Size of Steel Grating

The size of steel plate grating you tend to choose for different purposes is also a determinant of cost.

The bigger the carbon steel grating, the more steel would be used, and hence the price of the grating would increase and vice versa for the smaller size.

The layout of the Steel Grating

The layout of the carbon bar metal grating is a determinant of its cost.

If you choose plain grating, that won’t be priced much, but if you opt for galvanized grating, the price would be higher.

So, the impact of the layout on the cost of the steel grating is also one of the factors that lead to changes.

Vendor you choose

Every vendor offering carbon bar metal grating would have a different profit margin. Hence, the vendor you select will also determine the price of the steel grating.

Therefore, looking for different quotes from different vendors is suggested, and after comparison, the steel grating must be chosen.

Applications of Steel Gratings

There are various applications of stainless steel grating that are found in residential spaces as well as commercial spaces.

Industries like mining construction, food processing, and many more use steel gratings at their factories and working steups Some of the areas where the use of steel grating is applied are discussed below:

Walkways and Platforms

At factories, walkways and platforms are created using steel grating. These walkways are usually created at a separate place where certain tasks are carried out that involve having a rigid structure underneath.

The platforms made from steel grating are also chosen because this allows for handling heavy loads, and the factories where heavy loads are being kept usually tend to have these platforms of steel grating constructed.

Stair Treads and Fences

Steel grating adds strength to the structure of stairs if incorporated into the stair treads.

Hence when it comes to different places like pedestrian bridges and stairs or walkways, steel grating, these threads may also be made using steel gratings.

Adding steel grating into such structures usually makes them strong enough to handle the weight and offers a lot of safety.

Similarly, the fences used at commercial properties or on the sides of pedestrian bridges may also be made using steel gratings because they give added safety to anyone passing by.

Drainage and Ventilation Covers

Sewerage lines are also covered using steel gratings, which offer a ventilation system to the drainage and coverage that keeps anyone from falling into them.

Various industries where ventilation is a must because of chemical fumes also install steel gratings at different openings.

Mezzanine Floors

Various factories and other commercial setups might need an extra floor, and to create that mezzanine floor, they usually get the steel gratings installed.

This is a quick, cost-efficient, and convenient way to create mezzanines. Moreover, it is safe and can handle loads quite easily.

Conclusion

Steel gratings are widely popular nowadays, but before installing them, it is also essential to have a complete detailed idea of what these are and how they could benefit the user.

This guide has covered every detail of steel grating that would help you in the future.