Introduction

Classifying wire mesh is no easy feat – the variety of materials, sizes, and shapes can make it feel like a daunting task. But fear not! We’ve got some helpful hints to make the selection process seem less overwhelming. First, let’s break it down into categories – metal wire mesh, plastic and fiber mesh, and stainless steel mesh.

This article discusses the wire mesh features and functions. It also discusses the different types of wire mesh.

1. What is a wire mesh?

Wire mesh is a type of material that consists of a network of metal wires, which can be formed into simple shapes such as squares and rectangles. It is often used in construction, industrial manufacturing, and other applications where an increased level of flexibility is needed. Wire mesh offers several advantages over solid materials due to its unique characteristics.

One primary benefit of using wire mesh is that it can provide greater strength than comparable solid materials while still being lightweight and flexible. This makes it ideal for use in buildings or structures where extra reinforcement may be necessary without drastically adding extra weight or bulk.

Additionally, the weaving process used in creating wire mesh allows for airflow and ventilation within buildings, making it a popular choice for fencing panels, window screens, and other areas where airflow is important.

Wire mesh also has a range of materials available to suit different needs. Iron wire and stainless steel are the most common types, but aluminum, brass, and copper can be used depending on the desired characteristics. This wide range of material options allows for increased durability as well as aesthetic appeal. In addition, galvanized and PVC-coated wire meshes are available for more weather-resistant applications.

Overall, wire mesh is a versatile material with numerous advantages. Its combination of lightweight strength and flexibility makes it ideal for a range of applications, while its wide range of material options ensures that the perfect solution can be found for any situation. Its strong yet flexible properties make it an excellent choice in many areas of construction, industrial manufacturing, and other applications.

2. Different types of wire mesh

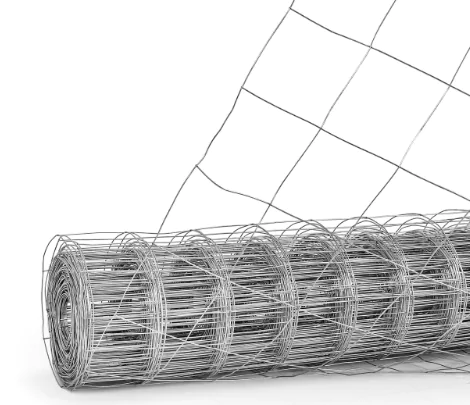

Metal wire mesh

Metal wire mesh is a versatile material that is used in a variety of applications across different industries. It is often fabricated from galvanized steel for increased durability and resistance to corrosion, making it ideal for many outdoor uses.

The metal wires are typically woven together in either a plain weave or twill weave pattern, giving the mesh its unique properties and characteristics. Metal wire mesh can be cut and formed into shapes to create grilles, filters, screens, and other products as required by the application.

It offers excellent strength-to-weight ratios, making it an ideal choice for fencing and security systems. Additionally, metal wire mesh has good thermal conductivity properties which make it suitable for use in heating and cooling systems. In conclusion, metal wire mesh is a material that has excellent properties and is suitable for a variety of applications across many industries.

Plastic wire mesh

Plastic wire mesh is a type of material that is increasingly being used for many applications. It provides excellent corrosion resistance and is lightweight, making it easy to transport and install. Furthermore, its flexibility allows it to be formed into different shapes to fit virtually any application.

Additionally, this type of mesh can come in various colors and thicknesses, making it highly customizable. Plastic wire mesh also offers superior strength compared to other materials when exposed to severe weather conditions or extreme temperatures. Overall, plastic wire mesh has become a popular choice among industries due to its durability and versatility.

Fiber wire mesh

Fiber wire mesh is a type of wire mesh that is suitable for use in a variety of applications. It consists of high-strength, lightweight fibers woven into interlocking patterns to form a durable yet flexible material.

Fiber wire mesh can be customized to meet specific strength and size requirements and is often used in the construction, aerospace, automotive, and agricultural industries. As fiber wire meshes are resistant to corrosion, heat, wear, and tear, they are also ideal for use as protective barriers or screens in various applications.

Additionally, fiber wire meshes have excellent tensile strength and ductility which make them an ideal choice for many engineering projects. All these qualities make fiber wire mesh an excellent solution for any application where durability and strength are essential requirements.

Stainless steel wire mesh

Stainless steel wire mesh is an extremely versatile material that comes in a variety of grades, alloys, and sizes. It has excellent strength and corrosion-resistant properties, making it suitable for many different applications. It can be used in filtration, screening, and separation processes as well as decorative uses such as bird cages and garden fences.

The stainless steel wire mesh provides superior protection from the elements and makes it ideal for outdoor applications where it may be exposed to harsh conditions. Its hard-wearing nature ensures that the product will remain functional for years to come with minimal maintenance required. This makes stainless steel wire mesh a great choice for any project requiring a durable material that can withstand wear and tear over time.

Aluminum wire mesh

Aluminum wire mesh is one of the most commonly used types of wire mesh due to its strength and corrosion resistance. It is also lightweight, making it easier to handle and install than other materials. It is an ideal choice for a variety of applications, including industrial, agricultural, residential, and commercial settings.

Aluminum wire mesh can be manufactured with various specifications such as size, shape, grade of aluminum alloy, and type of weave or stitch.

Additionally, it can be galvanized or coated with powder to increase its durability further. Its low cost makes it an attractive option for many buyers looking for durable material at an affordable price. Some common applications include window screens, sieves, bird cages, protective guards on machinery, and grilles in air conditioning.

Copper wire mesh

Copper wire mesh is a versatile material with many applications. It is often used for sieves and filters due to its malleability, corrosion resistance, and conductivity. Copper wire mesh can also be used in architectural projects such as fencing, cladding, and railings.

Additionally, copper wire mesh is popularly utilized in the aerospace industry for filtering systems and heat transfer systems. Its flexibility allows it to be bent into various shapes which makes it useful in intricate designs or structures.

Furthermore, copper wire mesh has excellent acoustic properties that make it ideal for soundproofing solutions. With these features combined, there are numerous uses for copper wire mesh in today’s world.

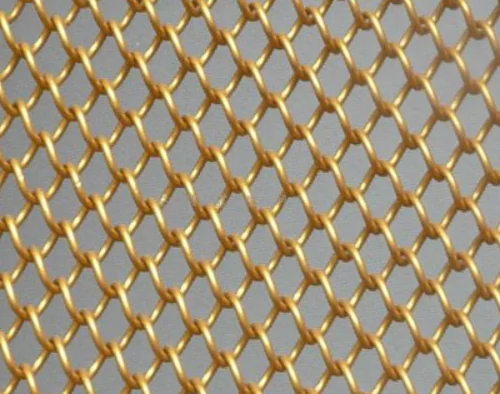

Brass wire mesh

Brass wire mesh is a type of metal mesh made from brass wires. It has strong corrosion resistance and is highly resistant to chemical attack, making it an ideal choice for industrial applications such as filtering, sifting, and sorting.

The flexibility and strength of brass also make it suitable for other uses including decorations or decorative accents in buildings. As with all wire meshes, the size of the openings and the thickness of the wires can be customized to accommodate specific needs.

Brass wire mesh offers exceptional long-term durability and reliability compared to other materials like plastic or stainless steel. For these reasons and more, brass wire mesh is often used in many fields ranging from scientific research to engineering products and consumer goods.

Bronze wire mesh

Bronze wire mesh is a type of metal mesh made from bronze, an alloy of copper and tin. It is an alloy used for centuries in a variety of applications due to its resistance to corrosion and enhanced durability.

Bronze wire mesh has excellent strength and can be woven into a wide range of materials, such as plain weave or twill weave, with various thicknesses. It also offers greater flexibility than other metals because it can be soldered together easily.

As such, bronze wire mesh is popular in products where precision and strength are paramount, including filters, baskets, strainers, screens, and even electrical components.

Mild steel wire mesh

Mild steel wire mesh is a popular choice for many applications due to its strength and durability. This type of wire mesh is made from low-carbon steel, which has been coated with zinc to prevent corrosion. The zinc coating also helps to increase the lifespan of this product, making it an attractive option for long-term use.

Mild steel wire mesh is available in a variety of sizes and gauges and can be customized according to the needs of a particular application. It is often used in architectural projects such as building facades or railing guards, but can also be used in other industrial or agricultural settings. Its versatility makes mild steel wire mesh ideal for a wide range of uses.

Pre-galvanized wire mesh

Pre-galvanized wire mesh is an economical solution for a range of applications. It has been hot-dip galvanized with zinc coating on both sides, giving it superior corrosion resistance and a long life span.

The wire mesh is very strong and durable, making it suitable for use in security fencing, industrial sieving, and agricultural purposes. Additionally, pre-galvanized wire mesh can be used to create decorative architectural features such as grilles and screens.

The mesh size and galvanization thickness can be customized to meet specific requirements. This makes pre-galvanized wire mesh an ideal choice for various projects requiring high performance at competitive prices.

Conclusion

In conclusion, wire mesh is a versatile material with many applications. It can be used in a variety of ways, from fencing to filtering and shielding. It is also important to note that wire mesh can be classified in several different ways, depending on the type of material used and the intended purpose.

Understanding the different types of wire mesh, their characteristics, and their uses are essential for selecting the most suitable product for any given application.