Introduction

Welded wire mesh is a popular material used in a variety of applications, from construction to agriculture. Its strength, durability, and versatility make it an excellent choice for many projects. In this article, we will discuss the advantages of welded wire mesh and why it may be the right choice for your next project.

Know more about the features and construction of welded wire mesh. Discover its benefits to various applications and industries.

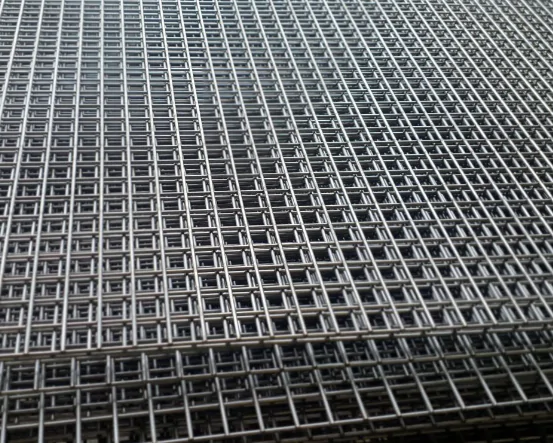

1. Basics of welded wire mesh

Welded wire mesh is a type of prefabricated mesh that is made up of interconnected wires that are welded together at their intersection points. The wire mesh can be made of various materials, such as steel, stainless steel, or galvanized steel.

It is typically used for fencing, reinforcement, and decorative purposes. It is available in a wide range of sizes and wire thicknesses, as well as a variety of materials, including galvanized steel, aluminum, PVC-coated steel, and stainless steel.

Welded wire mesh is highly durable and provides excellent strength and rigidity. It is also highly resistant to corrosion, making it an ideal choice for outdoor applications. Additionally, welded wire mesh is easy to install and can be cut and customized to meet specific requirements.

Welded wire mesh is constructed using a process known as spot welding. This process involves using a resistance spot welding machine to fuse two pieces of metal wire by applying electrical current to the ends of the wires.

The wires are then passed through a series of rollers that shape and roll them into a mesh pattern. The mesh is then cut to size and welded along the edges to create the finished product. The mesh can also be galvanized to improve its durability and resistance to corrosion.

2. Benefits of welded wire mesh

Welded wire mesh is a strong and durable material that is often used in construction, fencing, and other applications. It is usually made from galvanized steel wire and is available in a variety of different gauges, ranging from light-duty to heavy-duty.

The loading capacity of welded wire mesh will depend on the type of wire used, as well as the gauge of the wire. Generally, the heavier the gauge of wire, the higher the load capacity. Additionally, the size of the mesh opening will also affect the loading capacity, with larger openings providing greater load capacity.

In terms of durability, welded wire mesh is typically very strong and resistant to corrosion and weathering. It is also resistant to wear and tear and is often used in applications where the mesh will be exposed to high levels of stress.

Low maintenance

Welded wire mesh is extremely low maintenance, requiring no painting, staining, or treatment to maintain its aesthetic appeal. It is easy to clean, requiring only a light brushing with a soft-bristled brush and warm water. Welded wire mesh does not require any additional treatments, such as painting or staining, to maintain its appearance over time. The uniformity of the wire mesh means that it does not require any additional structural support to keep it in place.

Good ventilation

Welded wire mesh is an excellent choice for good ventilation because it has small openings that allow air to pass through, which can help to keep air moving in and out of space. It also has a strong and durable construction, so it can withstand harsh weather conditions without corroding.

The metal mesh provides enough space for air to flow through, allowing for natural ventilation and improved air circulation. In addition, the mesh can also provide an unobstructed view of the outside, which can provide a better connection to the outdoors. This can help improve air quality and reduce the buildup of allergens, dust, and other pollutants.

Welded mesh is also available in a variety of sizes and styles, so it can be used to create a customized ventilation solution that fits the needs of any space. In addition, it can be used to create barriers between different parts of a space, which can help to keep air from getting trapped in one area.

Easy installation and removal, reduce cost

Welded wire mesh is known for its easy installation. The installation of welded wire mesh is relatively straightforward. The mesh can be cut to size and then connected with wire ties, zip ties, or clamps.

If necessary, posts or other support structures can be installed in the ground to provide additional stability. The panels can then be placed into the support structure and secured with additional ties or clamps.

Welded wire mesh is also very easy to repair. If a section of fencing is damaged, the damaged section can be removed and replaced with a new piece of welded wire mesh. This makes it an ideal choice for areas that may experience wear and tear over time.

Its easy removal makes it a great choice for temporary projects, such as fence panels or trellises. To remove welded wire mesh, you’ll need a pair of bolt cutters or a sturdy pair of pliers.

- Start at one end of the mesh and cut the wires one at a time. If you’re using pliers, make sure to use a firm grip and pull each wire firmly.

- Once all the wires have been cut, the mesh can easily be removed from the structure it was attached to.

The process of removing welded wire mesh is simple. This makes it a great choice for quick, temporary projects that require a secure and sturdy material.

The cost of welded wire mesh is often lower than other fencing materials, such as chain links or wood. This makes it an ideal choice for those looking to save money on their project. Additionally, welded wire mesh is less labor-intensive and requires fewer materials, which can further reduce the cost.

Welded wire mesh can also be used to reduce the cost of other materials, such as concrete or asphalt. By using welded wire mesh as a reinforcement material, less expensive material is required, resulting in significant cost savings.

Conclusion

Welded wire mesh is an invaluable material that can be used in many different applications due to its strength, durability, cost-effectiveness, and ease of installation. It is a great choice for any construction project or home improvement project.