Introduction

Wire mesh is a versatile material used in a wide range of applications, from construction and fencing to filtration and decoration. However, choosing the right mesh size for your project can be challenging. In this guide, we will provide you with expert tips and considerations to help you choose the wire mesh of a suitable size for your specific application.

Whether you’re looking for durability, strength, or precision, our guide will help you make an informed decision and ensure the optimal performance of your wire mesh.

1. What is a wire mesh

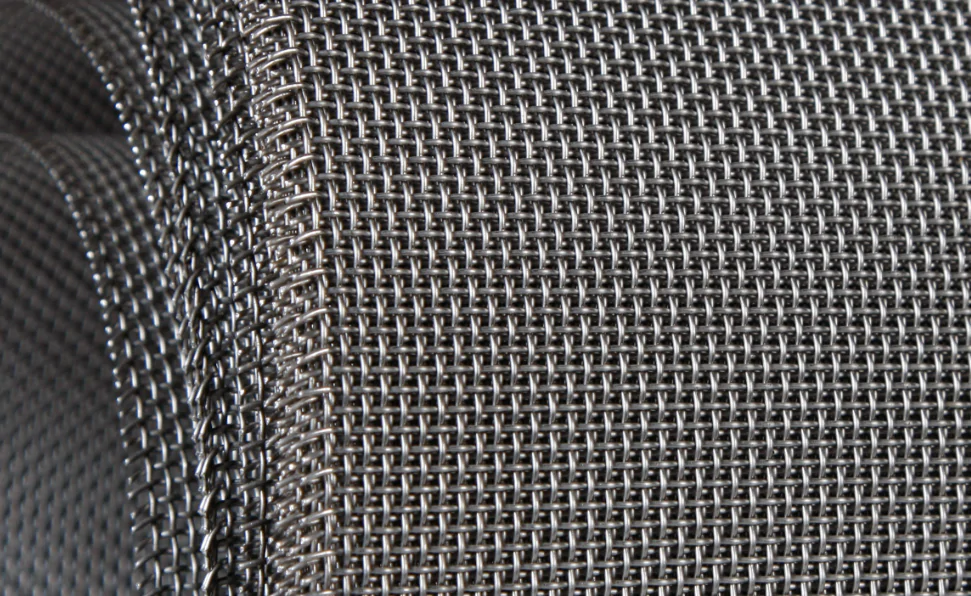

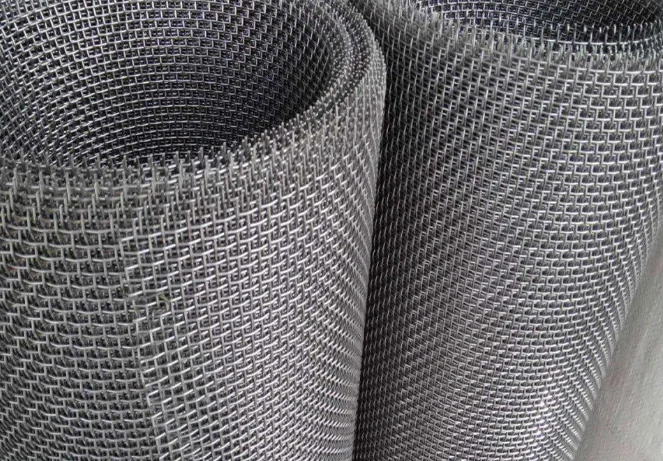

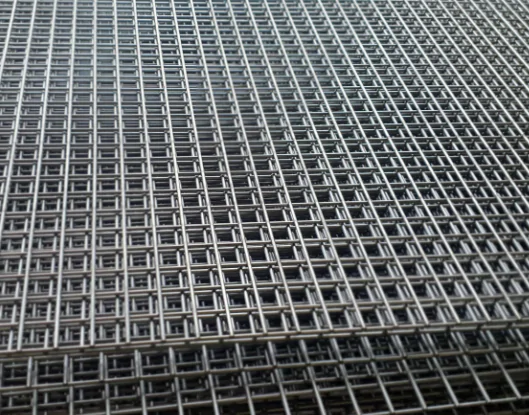

A wire mesh is a type of material made of interlocking metal wires, commonly used in a wide range of applications. Wire mesh is made by weaving or welding together wires of different materials, such as stainless steel, aluminum, brass, or copper. It can come in different shapes and sizes, with varying aperture or opening sizes and wire diameters.

Wire mesh is versatile and can be used for a variety of purposes, such as construction, fencing, filtration, decoration, and more. It can also be customized to fit specific applications, such as wire mesh screens for windows or doors, wire mesh baskets for storage or transportation, and wire mesh cages for animal enclosures or safety barriers.

Wire mesh is known for its strength, durability, and corrosion resistance, making it a popular choice for industrial and commercial applications.

2. Different sizes of wire mesh

Wire mesh comes in various sizes, depending on its intended use and application. The size of wire mesh is determined by two primary factors: aperture and wire diameter. Aperture refers to the space or opening between wires, while wire diameter refers to the thickness of the wire itself.

The aperture size can range from as small as 0.02mm for micro-meshes used in filtration, up to several inches for larger applications like fencing.

Here are some common sizes of wire mesh:

- Aperture sizes: 1/4″, 1/2″, 1″, 2″, 3″, 4″, 5″, 6″, 8″, 10″, and 12″.

- Wire diameters: 0.5 mm, 0.6 mm, 0.8 mm, 1.0 mm, 1.2 mm, 1.5 mm, 2.0 mm, 2.5 mm, 3.0 mm, and 4.0 mm.

- Mesh sizes: 2 mesh to 400 mesh.

- Sheet sizes: 4 ft x 8 ft, 4 ft x 10 ft, 5 ft x 10 ft, and 6 ft x 10 ft.

- Roll sizes: 4 ft x 50 ft, 5 ft x 100 ft, and 6 ft x 100 ft.

Wire diameter can range from as thin as 0.025mm to as thick as 12.7mm, depending on the intended use. The wire mesh size is usually expressed in terms of the number of openings per linear inch, also known as mesh count or mesh size.

The mesh count can range from as low as 2 mesh per linear inch for coarse screens, up to as high as 600 mesh per linear inch for fine sieves used in precision applications.

In general, the larger the mesh size, the more open space between wires, while smaller mesh sizes have smaller openings and thicker wires, providing more strength and durability.

3. Factors to consider when choosing sizes

Purpose

It is essential to consider the purpose when choosing the size of wire mesh because different applications require different mesh sizes and specifications. For instance, if you are using wire mesh for filtration purposes, a smaller aperture or opening size is necessary to ensure that only the desired particles pass through while blocking others.

In contrast, larger aperture sizes may allow unwanted particles to pass through, reducing filtration efficiency. Additionally, if you are using wire mesh for fencing, the wire diameter and aperture size need to be thick and strong enough to withstand impact, wear and tear, and environmental conditions.

Choosing the wrong size of wire mesh can lead to clogging, blockage, damage, or even failure of the application, resulting in maintenance, repair, or replacement costs. Therefore, by considering the intended use of the wire mesh and selecting the appropriate size and specifications, you can ensure optimal performance and durability of your application.

Loading capacity

It is important to consider the loading capacity when choosing the size of wire mesh because the wire diameter and aperture size determine the mesh’s strength and ability to withstand weight, pressure, and impact.

Choosing a wire mesh with a smaller diameter or larger aperture size than what is necessary for the intended loading capacity can result in the mesh deforming, breaking, or failing, leading to safety hazards, damage, or additional costs.

On the other hand, choosing a wire mesh that is too thick or small for the intended loading capacity may result in an unnecessary increase in weight, cost, and installation difficulty.

Therefore, it is crucial to consider the intended load or pressure of the application and select the appropriate wire diameter and aperture size that can provide sufficient strength and durability.

By selecting the correct wire mesh size, you can ensure that your application operates safely and effectively while minimizing maintenance, repair, or replacement costs.

Metal material

Considering the metal material is essential when choosing sizes of wire mesh because different metals have varying physical properties such as strength, flexibility, and corrosion resistance.

Choosing the appropriate metal material ensures that the wire mesh can withstand the intended application’s environmental and mechanical stresses.

For instance, if the wire mesh is intended for use in a corrosive environment, choosing a metal material with high corrosion resistance such as stainless steel is crucial to prevent premature failure of the mesh.

Therefore, considering the metal material when choosing sizes of wire mesh ensures that the mesh can perform optimally and has a long service life.

Environment

Considering the environment is essential when choosing sizes of wire mesh because different environments have varying conditions that can affect the wire mesh’s performance and longevity.

For example, if the wire mesh is intended for outdoor use, factors such as temperature changes, exposure to sunlight, and precipitation can cause the mesh to expand or contract, corrode, or degrade over time.

Similarly, if the wire mesh is intended for use in a corrosive or abrasive environment, such as a chemical plant or a mining site, choosing a mesh with high corrosion and abrasion resistance is crucial to prevent premature failure of the mesh.

Therefore, considering the environment when choosing sizes of wire mesh ensures that the mesh can withstand the intended application’s environmental stresses and has a long service life.

4. Additional tips for determining the sizes of wire mesh

Here are some additional tips for determining the sizes of wire mesh:

- Consider the aperture size

The aperture size refers to the distance between two adjacent wires. The aperture size affects the mesh’s strength, stiffness, and filtering properties. Therefore, choosing the appropriate aperture size is crucial to ensure that the mesh can perform optimally.

The aperture size determines the distance between the wires, and larger aperture sizes result in weaker and less stiff meshes than smaller aperture sizes. Therefore, applications that require high strength and stiffness, such as industrial filtration and heavy-duty fencing, require smaller aperture sizes.

- Consider the wire diameter

The wire diameter affects the mesh’s strength, stiffness, and flexibility. Choosing the appropriate wire diameter is crucial to ensure that the mesh can withstand the intended application’s mechanical stresses. Thicker wire diameters result in stronger and more durable meshes than thinner wire diameters.

- Consider the mesh’s weave pattern

The weave pattern affects the mesh’s filtering properties, airflow, and visibility. The weave pattern of the wire mesh is also a crucial factor to consider when determining its size because it affects the mesh’s stability, and appearance.

Different weave patterns have different aperture sizes, which can affect the mesh’s filtering properties and ability to support a particular load.

Additionally, some weave patterns may result in a more stable and aesthetically pleasing mesh than others, making them more suitable for certain applications. Therefore, the weave pattern should be selected based on the intended application and the desired properties of the mesh.

- Consider the intended application

The intended application affects the mesh’s size, shape, and material selection. Therefore, understanding the intended application’s requirements is crucial to choose the appropriate mesh size.

By considering these factors, you can choose the appropriate sizes of wire mesh that can perform optimally for the intended application and have a long service life.

Conclusion

Selecting the right wire mesh size for your application is essential for achieving optimal performance and durability. With this guide’s expert tips and considerations, you can confidently choose the wire mesh of suitable size for your specific application and achieve the desired results.