Have you ever wondered why our urban areas don’t flood every time it rains, or how large facilities manage water runoff? The answer often lies beneath our feet in the form of drainage systems. However, not all drainage systems are created equal. The choice of materials and design can significantly impact their efficiency and longevity.

Steel grating has emerged as a preferred choice for many engineers and city planners. Its robustness, durability, and ability to handle high loads make it an ideal component for drainage systems.

By diving deep into the world of steel grating in drainage systems, you’ll gain insights into its pivotal role in keeping our cities and facilities dry. Stay with us as we unravel the intricacies of this unsung hero of urban planning, ensuring you’re well-equipped with knowledge that might just come in handy someday.

What is Steel Grating?

Steel grating is a framework of intersecting bars and crossbars made primarily from steel. These bars are joined together by welding, riveting, or pressure-locking to form a grid-like pattern. This structure is commonly used in various applications, including walkways, platforms, and drainage systems.

Definition and basic structure of steel grating

Steel grating is essentially a collection of steel bars positioned vertically and horizontally to form a consistent, grid-like pattern. The intersections of these bars are securely joined, ensuring the grating’s stability.

Types of steel grating

- Welded Grating: This is the most common type of steel grating, where the crossbars are welded to the bearing bars, offering a high-strength and cost-effective solution.

- Press-locked Grating: Here, the crossbars are set into pre-cut grooves on the bearing bars and locked into place using high pressure.

- Swage-locked Grating: This type is made by interlocking cross rods into the diamond-shaped openings of the bearing bars, ensuring a strong bond. It’s particularly suitable for areas with heavy loads and high impact.

Key properties

| Durability | Steel grating is known for its long-lasting nature, especially when treated or coated to prevent rust. |

| Strength | Its robust construction allows it to support heavy weights without deforming. |

| Corrosion Resistance | With proper coatings, steel grating can resist the corrosive effects of chemicals and weather. |

Benefits of Using Steel Grating in Drainage Systems

High Load Capacity

One of the standout benefits of steel grating is its ability to handle immense loads. This makes it ideal for areas with heavy traffic, such as roads and industrial zones.

Durability

Thanks to its corrosion-resistant properties, steel grating boasts a long lifespan. When treated with protective coatings, it can withstand the elements, ensuring longevity.

Safety

The grid-like structure provides a non-slip surface, reducing the risk of accidents, especially in wet conditions.

Easy Maintenance

Steel grating has a self-cleaning nature. As water flows through it, debris is naturally washed away, minimizing the need for regular upkeep.

Aesthetics

With various designs and finishes available, steel grating can be both functional and visually appealing, complementing urban and architectural designs.

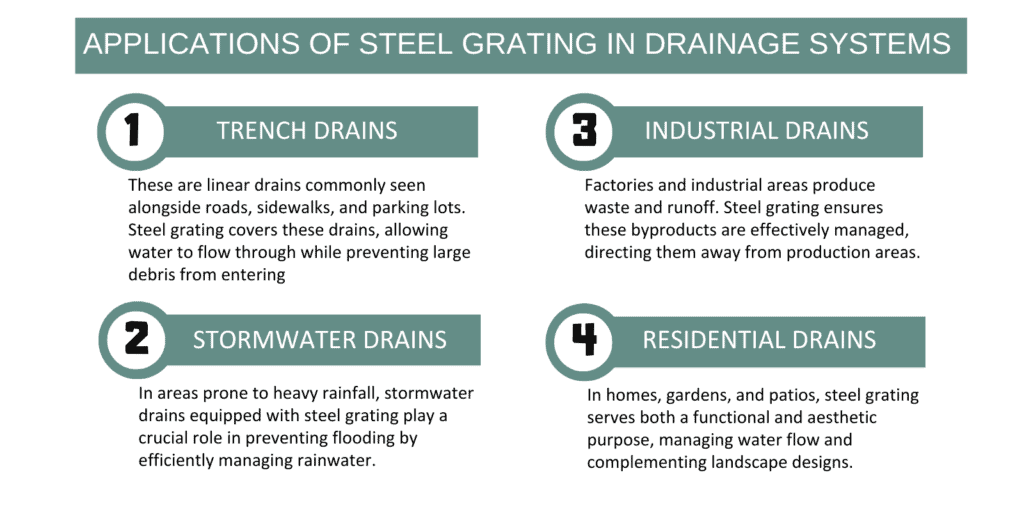

Applications of Steel Grating in Drainage Systems

Installation and Maintenance

Steps for installing steel grating in drainage systems

| 1 | Measure and mark the area where the grating will be placed |

| 2 | Prepare the site by excavating and leveling |

| 3 | Lay down the steel grating, ensuring it fits snugly |

| 4 | Secure the grating using appropriate fasteners or anchors |

| 5 | Apply protective coatings if necessary |

Tips for ensuring longevity and optimal performance

- Regularly inspect the grating for signs of wear or damage.

- Clean the grating periodically to prevent debris buildup.

- Reapply protective coatings as needed.

Common maintenance practices and potential issues

While steel grating requires minimal maintenance, it’s essential to watch out for rust, especially in untreated grates. Regular cleaning and the occasional reapplication of protective coatings can mitigate this.

Environmental Impact

Sustainable Drainage Solutions

Steel grating promotes the efficient flow of water, reducing surface runoff and the risk of flooding. This aids in recharging groundwater levels and preventing soil erosion.

Recycling and Reusability

Steel grating is recyclable. At the end of its lifecycle, it can be repurposed or melted down to produce new steel products, promoting a circular economy.

Impact on Water Quality and Ecosystem

By filtering out large debris, steel grating ensures that only relatively clean water enters our waterways. This helps in preserving aquatic ecosystems and maintaining water quality.

Conclusion

Having delved deep into the realm of steel grating and its pivotal role in drainage systems, it’s evident that this material stands as a cornerstone in modern infrastructure. From its intricate design and types to its myriad of applications, steel grating ensures our urban areas remain functional and flood-free.

Drawing from years of hands-on involvement in the field, I’ve witnessed the transformative impact of steel grating in various settings, from bustling cities to serene residential areas. This knowledge, coupled with rigorous research and collaboration with industry experts, has fortified my understanding of this subject.

It’s essential to approach such topics with a commitment to accuracy and integrity, ensuring that readers receive reliable and actionable insights. As you navigate the world of drainage systems and consider the materials to employ, remember the unparalleled benefits of steel grating. Its blend of durability, aesthetics, and environmental impact positions it as a top choice for forward-thinking urban planners and engineers.