Have you ever wondered why certain materials last longer in challenging environments while others deteriorate quickly? The durability of materials is paramount, especially in industries where structures are exposed to harsh conditions. Steel grating, a popular choice for many industrial and architectural applications, stands out in this regard.

Steel grating is renowned for its exceptional durability and longevity, especially in harsh environments. Made from high-strength steel, it resists corrosion, bears heavy loads, and tolerates extreme temperatures. As you delve deeper into this article, you’ll discover the intrinsic qualities of steel grating that make it a preferred choice for challenging conditions, ensuring you make informed decisions for your projects.

The Composition of Steel Grating

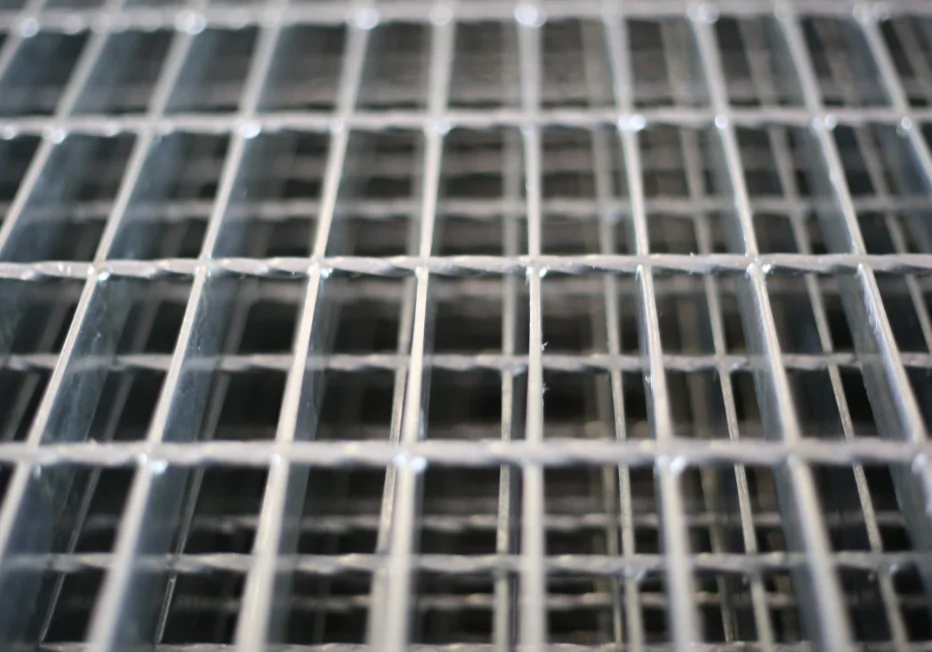

Steel grating is a product of meticulous engineering, designed to offer both strength and versatility. At its core, it’s made from high-quality steel bars that are positioned vertically and horizontally to form a grid-like pattern. These bars are often joined by welding or by using pressure-locked methods.

The type of steel used plays a pivotal role in determining the grating’s durability. Carbon steel, for instance, is a common choice due to its inherent strength. However, for added resistance against corrosion, steel gratings can be galvanized, a process where a protective zinc layer is applied.

Alternatively, stainless steel, known for its anti-corrosive properties, can also be used. The inherent qualities of steel, such as its tensile strength and malleability, make it an ideal candidate for grating, ensuring it remains robust even under constant use.

Harsh Environments Defined

When we talk about “harsh environments,” we refer to conditions that are particularly challenging for materials and structures. Coastal areas, for example, expose structures to saltwater, which can be corrosive. Industrial zones might expose materials to a range of chemicals, some of which can be highly reactive. Then there are places with extreme temperature fluctuations, from scorching heat to freezing cold.

Such environments are not just challenging; they test the very limits of materials. The constant exposure to corrosive elements, extreme pressures, or drastic temperatures can lead to wear and tear, degradation, and ultimately, failure of many materials. This is why choosing the right material, one that can withstand these challenges, becomes crucial.

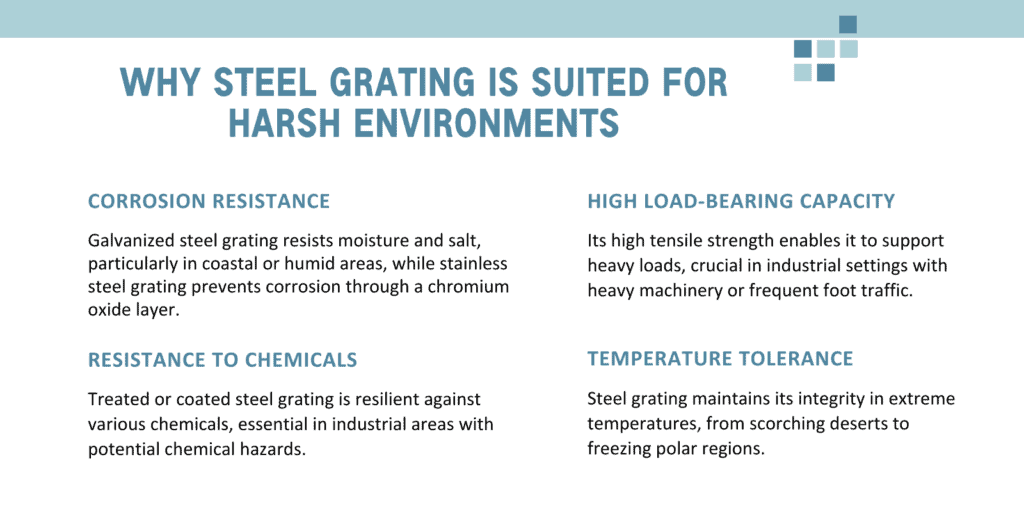

Why Steel Grating is Suited for Harsh Environments

Corrosion Resistance

One of the primary threats in coastal or humid environments is corrosion. Steel grating, when galvanized, offers a significant defense against this. The zinc coating acts as a barrier, preventing moisture and salt from reaching the steel beneath. Stainless steel grating, with its chromium content, forms an invisible layer of chromium oxide, which further prevents corrosion.

High Load-Bearing Capacity

Steel, by its very nature, boasts a high tensile strength. This means steel grating can handle heavy loads, a feature especially important in industrial settings. Whether it’s the weight of machinery, vehicles, or a constant flow of foot traffic, steel grating remains unyielding and dependable.

Temperature Tolerance

Steel’s ability to maintain its structural integrity across a wide temperature range is commendable. Whether exposed to the blazing sun in desert environments or the freezing conditions of polar regions, steel grating remains stable and retains its shape and strength.

Resistance to Chemicals

In industrial settings, the exposure to chemicals is a real concern. Steel grating, especially when treated or coated, showcases resilience against a variety of chemicals. This resistance ensures that the grating doesn’t degrade quickly, even when exposed to potential chemical hazards.

Comparative Analysis

When evaluating the durability of steel grating, it’s essential to compare it with other prevalent grating materials, such as aluminum and fiberglass.

Aluminum Grating

- Lightweight and offers decent corrosion resistance

- Lacks in strength and load-bearing capacity compared with steel grating

- In highly alkaline or acidic environments, aluminum may corrode faster than treated or stainless steel

Fiberglass Grating

- Lightweight, has excellent corrosion resistance

- Useful in chemical industries

- In terms of sheer mechanical strength and impact resistance, steel grating has the upper hand

Maintenance and Care

Ensuring the longevity of steel grating in harsh environments goes beyond its initial design and material selection; regular maintenance plays a crucial role.

| Periodic Inspections | Regular checks for signs of wear, corrosion, or damage can help in early detection and rectification. This not only ensures safety but also extends the grating’s lifespan. |

| Cleaning Methods | Depending on the environment, steel grating can accumulate dirt, chemicals, or salt. Regular cleaning, using appropriate solvents or simply freshwater, can prevent long-term damage. |

| Treatments and Coatings | For added protection, especially in extremely harsh conditions, additional coatings or treatments can be applied. This might include anti-corrosive paints or specialized coatings that offer resistance against specific chemicals. |

Conclusion

Throughout this exploration, the resilience and adaptability of steel grating in confronting the challenges of harsh environments have been evident. Its superior load-bearing capacity, resistance to corrosion, and ability to withstand extreme temperatures make it an unparalleled choice in the realm of grating materials.

As industries and architects navigate the demands of their projects, especially those situated in challenging conditions, the choice of steel grating emerges not just as a preference but a necessity. Embracing its unmatched durability ensures a foundation that stands the test of time, weather, and wear.