Have you ever wondered why your steel grating seems to wear out faster than expected? Steel grating, often considered the backbone of various industries due to its versatility and durability, can unfortunately degrade quickly if not maintained properly. Over time, factors like constant exposure to the elements, accumulated debris, and regular wear and tear can significantly shorten its lifespan.

Steel grating is an investment, and like all investments, it requires care and attention. By implementing regular maintenance practices, you can significantly prolong the life of your steel grating, ensuring it remains sturdy and reliable for years. Not only will this save you money in the long run by reducing replacement costs, but it also ensures safety for all users. So, let’s dive in and explore these essential maintenance tips. Your steel grating will thank you, and you’ll reap the benefits of a long-lasting, durable infrastructure.

Understanding Steel Grating

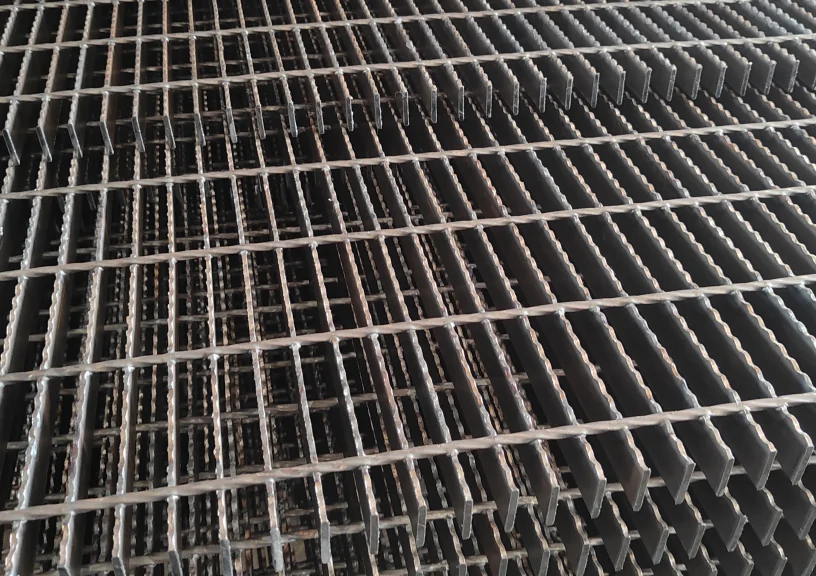

Steel grating is a framework of crossed bars typically made of metal and designed to act as a supportive surface. The pattern of intersecting bars creates open spaces that allow for ventilation and the passage of light, making it a preferred choice in various construction and industrial applications. These grates can often be seen in walkways, bridges, drainage systems, and industrial plants.

Selecting the appropriate type of steel grating is crucial. The environment and the specific needs of the application determine which type of grating is best. For instance, areas exposed to corrosive chemicals might require a more resistant type of steel or a protective coating, while pedestrian walkways might focus more on anti-slip properties. Investing time in understanding the different types and their suitability will ensure long-term functionality and safety.

Regular Inspection

Routine inspections of steel grating are essential to ensure its longevity and safety. Over time, even the most robust materials can show signs of wear and tear.

During inspections, keep an eye out for visible signs of rust, any indications of warping or bending, and other structural issues that might compromise the grating’s integrity. Catching these early can prevent minor issues from becoming significant, costly problems. A periodic and thorough check ensures the grating remains reliable and helps in planning for any necessary interventions.

Cleaning Techniques

A clean steel grating is not just aesthetically pleasing but also functional. Debris, dirt, and other particles can accumulate in the spaces between the bars, potentially leading to blockages or creating spots conducive to rust formation.

| Regular cleaning | A soft brush can effectively remove most of the accumulated debris |

| Deeper cleaning | Water rinsing combined with a mild detergent |

After cleaning, ensure the grating is thoroughly dried to prevent moisture-induced rusting. It’s essential to avoid harsh chemicals or abrasive tools that might damage the grating’s surface or its protective coating.

Rust Prevention and Treatment

Rust is a primary concern for steel structures, and grating is no exception. Rust not only degrades the aesthetics but also compromises the strength and integrity of the grating.

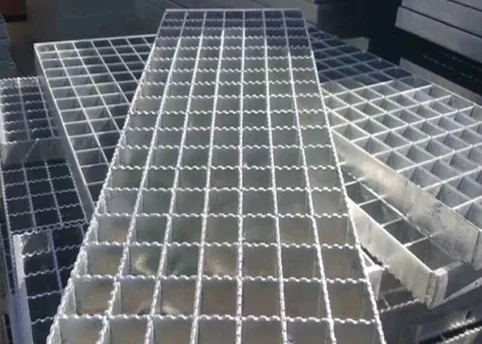

Prevention is always better than cure. Regularly applying rust-resistant coatings can offer a protective shield against moisture and oxidation. Proper drainage is another preventive measure; standing water is a rust magnet. Opting for galvanized steel grating, where the steel is coated with a protective layer of zinc, offers added rust resistance.

However, if rust has already formed, it’s essential to treat it promptly. Start by using rust removers or opting for sandblasting to get rid of the corroded layers. Once cleaned, re-coating the grating will restore its protective barrier and extend its lifespan.

Load-bearing Precautions

Steel grating is designed to bear loads, but like any material, it has its limits. Exceeding the load capacity can lead to early degradation, creating safety risks.

- Regularly reviewing the weight-bearing capacities and ensuring they’re not surpassed is essential.

- Avoid point loads or concentrated weights on small areas, as these can lead to stress points that may eventually cause bending or warping.

- For long-term durability and safety, ensure the weight on the grating is distributed evenly.

Protective Coatings and Sealants

Steel grating can be exposed to a variety of environmental factors that can hasten its degradation. Thankfully, numerous coatings and sealants are available to provide an added layer of protection. Epoxy coatings, for instance, are excellent for chemical resistance, while polyurethane coatings offer UV protection.

The frequency of application will vary based on the product, but it’s usually recommended to re-apply protective coatings every few years, or when visible wear and tear appear. By regularly maintaining these protective layers, the grating’s lifespan can be significantly extended.

Environmental Considerations

Repairs and Replacements

Even with the best maintenance practices, there might come a time when a section of your steel grating needs repair or replacement. Regular inspections will help identify these spots before they become hazardous. When repairing, ensure the methods used are in line with the original manufacturing standards to maintain uniformity and strength. If a replacement is needed, always ensure that the new section seamlessly integrates with the old, both in terms of fit and in material compatibility.

Conclusion

Maintenance isn’t just about preserving appearances; it’s about ensuring the long-term functionality, safety, and reliability of your steel grating. By understanding the nuances of steel grating, from environmental challenges to load-bearing capacities, and by regularly implementing protective and corrective measures, you can ensure that your grating serves you well for years.

Stay proactive, keep an eye on potential issues, and always prioritize timely interventions. Your steel grating, your wallet, and most importantly, the people who rely on it, will thank you.