Introduction

Welded wire mesh is an essential component in construction projects, providing structural strength and stability. Did you know that producing welded wire mesh involves a fascinating process?

In this article, we’ll delve into how welded wire mesh is made and the benefits it provides for construction projects. Join us as we explore transforming raw wire into an essential building material.

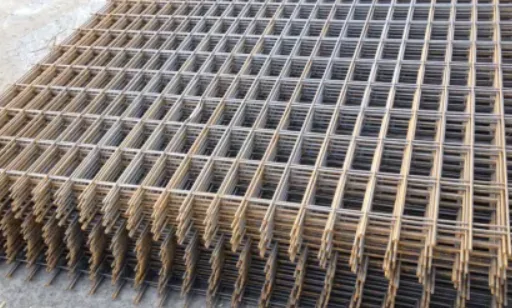

1. What is a wire mesh?

Wire mesh is a versatile material widely used in various industries, from construction to manufacturing. It is a grid-like structure with interconnected wires forming a mesh pattern. This material can be made from different metals, such as stainless steel, copper, aluminum, plastics, and synthetic materials.

There are two primary types of wire mesh: woven and welded. Interlacing wires create woven wire mesh in a specific pattern, whereas welded wire mesh is created by welding individual wires together at their intersection points. Both types of wire mesh can be customized to meet specific needs and come in different sizes and shapes.

Wire mesh has many applications, such as filtration, fencing, sieving, and construction. In the construction industry, wire mesh is commonly used in reinforced concrete structures, as it provides additional strength and stability. It is also used for safety barriers and fencing on construction sites.

Wire mesh is a popular material for many industrial and commercial applications due to its unique properties. Its grid-like structure provides excellent strength and stability, making it ideal for heavy-duty applications. Additionally, wire mesh is highly durable and corrosion-resistant, making it suitable for outdoor applications.

In manufacturing, wire mesh is used for sieving and filtering in various processes, such as food processing, chemical production, and pharmaceutical manufacturing. It is also used for safety purposes in machinery and equipment to prevent injury or damage.

2. How welded wire mesh is made

Step 1: Straightening and cutting

Wire rods are first fed through a machine that straightens and cuts them to the required length. Precision cutting is essential to ensure the consistency of the mesh. This step ensures that each wire rod has the correct length and size.

Step 2: Inserting into the machine

The straightened and cut wire rods are then inserted into a machine that weaves and welds them together. The types of machines used for this process can vary depending on the desired end product. Some common machines used for welded wire mesh include wire mesh fences, concrete reinforcement, and steel reinforcing.

Step 3: Spot welding

The wire rods are welded at specific points to create the desired pattern and strength. Different welding techniques are used in the process, such as resistance spot welding and MIG welding. The quality of the welding process can significantly affect the overall quality of the welded wire mesh.

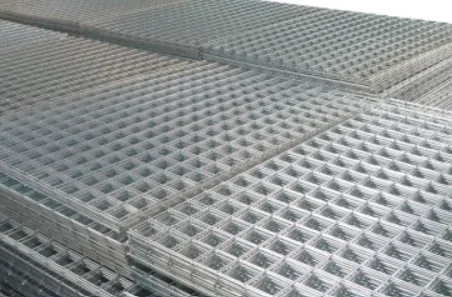

Step 4: Rolling

Finally, the welded wire mesh is rolled to create large sheets or rolls that can be easily transported and installed at construction sites or other locations. Proper rolling techniques are essential to avoid damaging the mesh during transportation. Once the wire mesh is rolled, it is ready for use in various applications.

3. Benefits of welded wire mesh

Easy installation

One of the main benefits of welded wire mesh is its ease of installation. The mesh can be easily cut to size and shaped to fit any space or application. This makes it an ideal material for construction projects where quick and efficient installation is essential.

For example, welded wire mesh is commonly used in concrete reinforcement, where it can be quickly cut and installed to provide additional strength and stability to the structure.

Sturdy

Another significant benefit of welded wire mesh is its strength and durability. The welding process ensures the mesh is solid and sturdy, making it ideal for heavy-duty applications.

Welded wire mesh can withstand extreme temperatures and harsh environmental conditions, making it suitable for use in outdoor applications. For example, welded wire mesh is commonly used in fencing and safety barriers, where its strength and durability are essential.

Ventilation

Welded wire mesh also offers excellent ventilation, making it ideal for use when airflow is necessary. The mesh pattern allows air to circulate freely while providing strength and stability. This makes it an ideal material for use in filtration and sieving applications.

For example, welded wire mesh is commonly used in food processing, where proper ventilation is essential to maintain the quality and safety of the product.

Conclusion

Understanding how welded wire mesh is made can provide insight into its unique properties and benefits. From easy installation to excellent ventilation and sturdiness, welded wire mesh offers many advantages in construction, manufacturing, and other applications. Discover more about this fascinating material in our comprehensive article.