Introduction

Looking to learn about woven wire mesh? Look no further! This beginner’s guide covers everything you need to know about woven wire mesh, including its uses, types, and manufacturing process. Whether you’re a novice or an expert, this comprehensive guide has something for everyone. Start your journey to becoming a woven wire mesh pro today!

Know the basics of woven wire mesh including its features, types, benefits, and how it is made. Learn about the different applications of this wire mesh to various industries.

1. Basics of woven wire mesh

Woven wire mesh is a type of material that is made by interweaving individual wires together at right angles to create a grid-like pattern.

It is commonly used for filtration, separation, reinforcement, and decorative purposes, and is available in a wide variety of materials, wire gauges, and mesh sizes to suit various applications. Woven wire mesh is known for its strength, durability, and versatility, making it a popular choice in many different industries.

Features

Strength and durability: Woven wire mesh is strong and durable, which makes it suitable for use in demanding environments.

Versatility: Woven wire mesh is available in a wide variety of materials, wire gauges, and mesh sizes, making it suitable for a range of applications.

Customization: Woven wire mesh can be customized to meet specific requirements, such as the size and shape of the mesh openings, the material of the wires, and the overall dimensions of the mesh.

Filtration: Woven wire mesh can be used for filtration and separation applications, such as separating particles from fluids, air filtration, and oil filtration.

Decorative: Woven wire mesh can be used for decorative purposes, such as in architectural applications, interior design, and art installations.

Good airflow and visibility: Woven wire mesh allows for good airflow and visibility, making it suitable for applications such as insect screens, security screens, and fencing.

Benefits

Easy to clean: Woven wire mesh is easy to clean and maintain, which makes it suitable for use in applications where hygiene is important.

Cost-effective: Woven wire mesh is a cost-effective solution for many applications, as it offers a good balance between price and performance.

High-temperature resistance: Woven wire mesh is resistant to high temperatures, making it suitable for use in applications where heat resistance is important, such as in industrial ovens and furnaces.

Corrosion resistance: Woven wire mesh can be made from corrosion-resistant materials, making it suitable for use in harsh environments.

2. Different types of woven wire mesh

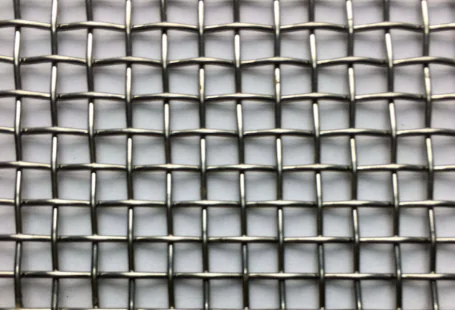

Plain Square woven mesh

Plain square woven mesh, also known as plain weave wire mesh, is a type of woven wire mesh where the warp (vertical) and weft (horizontal) wires are interwoven to form a square pattern. In this type of weave, each wire passes over one wire and under the next wire in both the warp and weft directions, resulting in a simple and uniform weave pattern.

The wires are usually of the same diameter and are woven with equal spacing to create a mesh with square openings. Plain square woven mesh is commonly used for filtration, sorting, and screening applications where a uniform and stable mesh is required.

It is available in various materials, including stainless steel, brass, and copper, and can be customized to suit specific requirements such as mesh size, wire diameter, and overall dimensions.

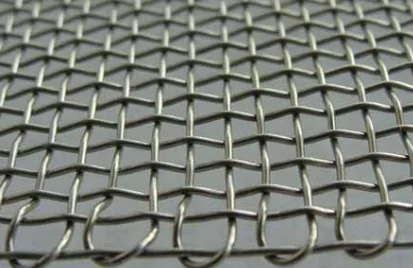

Twill Square woven mesh

Twill square woven mesh, also known as twilled weave wire mesh, is a type of woven wire mesh that is similar to plain square woven mesh but has a different weave pattern. In twill square woven mesh, the warp and weft wires are interwoven to create a diagonal pattern.

This is achieved by passing each weft wire over two or more warp wires, and then under one or more warp wires in a staggered pattern, creating a distinctive diagonal line. The weave pattern produces a strong and stable mesh that is suitable for heavy-duty applications.

Twill square woven mesh is commonly used in industries such as aerospace, mining, and automotive for applications such as filtering, sieving, and reinforcing. It is available in various materials, including stainless steel, brass, and bronze, and can be customized to suit specific requirements such as mesh size, wire diameter, and overall dimensions.

Plain Dutch woven mesh

Plain Dutch woven mesh is a type of woven wire mesh that is characterized by a fine mesh structure and high filtration capacity.

In this type of weave, the warp wires are thicker and more widely spaced than the weft wires, resulting in a tightly woven mesh structure with smaller openings. The weft wires are woven through the warp wires in a plain weave pattern, creating a stable and uniform mesh surface.

Plain Dutch woven mesh is commonly used for high-precision filtration and separation applications where a high degree of filtration accuracy and efficiency is required. It is often used to filter liquids, gases, and other fine particles in industries such as chemical processing, food and beverage, pharmaceuticals, and oil and gas.

Plain Dutch woven mesh is available in a range of materials, including stainless steel, brass, and nickel, and can be customized to suit specific requirements such as mesh size, wire diameter, and overall dimensions.

Twill Dutch woven mesh

Twill Dutch woven mesh is a type of woven wire mesh that is similar to plain Dutch woven mesh but has a different weave pattern. In twill Dutch woven mesh, the warp wires are woven in a twill weave pattern, which creates a diagonal pattern on the surface of the mesh. This weave pattern allows for a tighter mesh structure and smaller openings than plain Dutch woven mesh.

In twill Dutch woven mesh, the warp wires are typically thicker and more widely spaced than the weft wires, while the weft wires are finer and more tightly spaced. The twill weave pattern is created by passing the weft wire over and under several warp wires, and then shifting the weave pattern by one wire in the next row.

Twill Dutch woven mesh is commonly used for applications where high-precision filtration is required, such as in the aerospace, automotive, and chemical industries. It is also used for particle separation and sizing, as well as for sieving and sorting applications.

Twill Dutch woven mesh is available in various materials, including stainless steel, brass, and nickel, and can be customized to suit specific requirements such as mesh size, wire diameter, and overall dimensions.

3. How woven wire mesh is made

Woven wire mesh is made by interweaving wires in a specific pattern to create a mesh structure with uniform openings. The process of making woven wire mesh involves the following steps:

- Wire drawing: The first step in making woven wire mesh is wire drawing, where metal wires are drawn through a die to reduce their diameter to the desired size. The wires may be made of various materials such as stainless steel, copper, brass, or other alloys.

- Warp wire preparation: In this step, the warp wires are prepared by winding them onto a large spool or beam. The wires are aligned parallel to each other and under tension to ensure they are straight and uniform in size.

- Weft wire preparation: The weft wires are cut to the required length and are often rolled onto a smaller spool or bobbin.

- Weaving: The next step is the actual weaving process, where the warp and weft wires are interlaced to form the mesh structure. There are different types of weaving patterns, including plain weave, twill weave, and Dutch weave, which create different mesh structures.

- Cutting and finishing: Once the weaving process is complete, the woven wire mesh is cut to the desired size and shape. The edges may be trimmed, and the mesh may be flattened or rolled, depending on its intended use.

- Cleaning and inspection: The final step is to clean and inspect the woven wire mesh for defects or irregularities. The mesh is often cleaned using a chemical or mechanical process to remove any debris or residue. It is then inspected to ensure it meets the required specifications for mesh size, wire diameter, and overall quality.

4. Applications of woven wire mesh

Industrial field

- Filtration and separation: Woven wire mesh is commonly used for filtration and separation applications in industries such as chemical processing, oil and gas, and food and beverage. It is used to filter liquids, gases, and other fine particles.

- Reinforcement and support: Woven wire mesh is often used as reinforcement or support material in the construction industry. It can be used to strengthen concrete or other materials and to provide stability and support for walls, roofs, and other structures.

- Screen printing: Woven wire mesh is used in screen printing to create stencils or screens for printing on various surfaces, such as textiles, paper, and plastics.

Agricultural field

- Animal containment: Woven wire mesh is used for animal containment and fencing in agricultural fields. It can be used to create enclosures for livestock, poultry, and other animals.

- Crop protection: Woven wire mesh is also used for crop protection, such as bird netting to prevent birds from damaging crops.

Filtration

- Water filtration: Woven wire mesh is used for water filtration in industries such as municipal water treatment, desalination, and wastewater treatment.

- Air filtration: Woven wire mesh is used for air filtration in HVAC systems, industrial ventilation, and clean room environments.

These are just a few examples of the many applications of woven wire mesh. Its versatility and durability make it a popular choice for a wide range of industrial, agricultural, and filtration applications.

Conclusion

Woven wire mesh is a versatile material used in many industries and applications. It is easy to work with and provides a variety of benefits. With a basic understanding of its properties and uses, anyone can make use of this great material. Now that you know more about woven wire mesh, you’re ready to get started on your project or explore more possibilities.