Introduction

Do you know which grade of stainless steel is best for your project? It depends on your specific needs. Are you looking for a wire mesh that can withstand harsh environments, resist corrosion, or handle high temperatures? By selecting the appropriate grade of stainless steel, you can ensure that your wire mesh performs optimally and lasts for years to come.

In this guide, we’ll provide an in-depth overview of the most common grades of stainless steel wire mesh, including their unique properties and applications. Whether you’re looking to improve filtration efficiency, enhance safety, or optimize performance, this guide will equip you with the knowledge needed to make an informed decision when selecting a grade of stainless steel wire mesh.

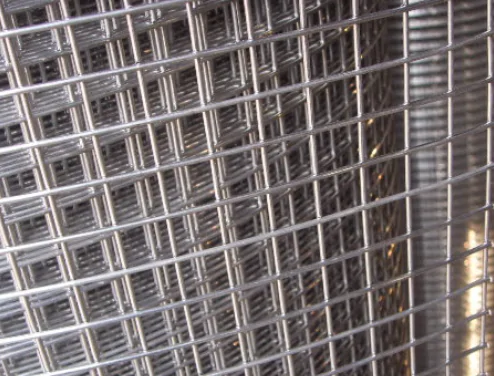

1. What is stainless steel wire mesh?

Stainless steel wire mesh is a woven material made up of interlocking metal wires arranged in a grid-like pattern. It’s commonly used in various industries, including construction, agriculture, and food processing, due to its exceptional properties.

Stainless steel wire mesh is highly durable, corrosion-resistant, and able to withstand heavy loads while remaining lightweight. It’s also highly customizable, available in different grades, weaves, and aperture sizes, making it an ideal choice for a wide range of applications. Moreover, stainless steel wire mesh is easy to clean and maintain, making it a hygienic choice for use in the food and beverage industry.

2. Features and benefits

Stainless steel wire mesh is a versatile material that offers several features due to its unique composition and structure. Here are some of the most notable features of stainless steel wire mesh:

Corrosion Resistance

Stainless steel wire mesh is highly resistant to corrosion, even in harsh environments where it’s exposed to moisture or chemicals. This is due to the presence of chromium in stainless steel, which creates a passive layer that prevents rust and other forms of corrosion.

Strength and Durability

Stainless steel wire mesh is lightweight yet sturdy enough to withstand heavy loads without deformation. It’s also highly durable and can withstand harsh conditions, making it ideal for use in industrial and commercial applications.

Customizability

Stainless steel wire mesh is available in various grades, weaves, and aperture sizes, allowing it to be tailored to meet specific filtration, insulation, or protective requirements.

Hygiene and Easy Maintenance

Stainless steel wire mesh is easy to clean and maintain, making it a popular choice in the food and beverage industry. Its smooth surface makes it difficult for bacteria and other contaminants to adhere to the material, ensuring hygiene and safety.

Cost-Effectiveness

Although the initial cost of stainless steel wire mesh may be higher than other materials, its durability and longevity make it a cost-effective investment in the long run.

Versatility

Stainless steel wire mesh can be used in a wide range of applications, including construction, agriculture, and pharmaceuticals, thanks to its unique properties.

3. Different grades of stainless steel wire mesh

Stainless steel wire mesh is available in various grades, each with its unique composition and properties. Here’s an overview of the key features of three common grades of stainless steel wire mesh:

- 304 Stainless Steel Wire Mesh

This grade of stainless steel wire mesh is the most commonly used due to its excellent corrosion resistance, durability, and versatility.

It contains 18% chromium and 8% nickel, which create a passive layer that prevents rust and other forms of corrosion. 304 stainless steel wire mesh is suitable for use in various industries, including food processing, pharmaceuticals, and construction.

- 316 Stainless Steel Wire Mesh

This grade of stainless steel wire mesh is even more corrosion-resistant than 304 stainless steel, making it ideal for use in harsh environments where it’s exposed to saltwater or chemicals.

It contains 16% chromium, 10% nickel, and 2% molybdenum, which enhance its corrosion resistance and strength. 316 stainless steel wire mesh is commonly used in marine applications, food processing, and chemical processing.

- 321 Stainless Steel Wire Mesh

This grade of stainless steel wire mesh contains 18% chromium and 10% nickel, similar to 304 stainless steel, but with the addition of titanium. The presence of titanium enhances its resistance to high temperatures, making it ideal for use in high-temperature applications such as heat exchangers and furnace parts. It’s also highly resistant to corrosion, making it suitable for use in harsh environments.

Each grade of stainless steel wire mesh has its unique composition and properties, making them suitable for specific applications. 304 stainless steel wire mesh is versatile and durable, while 316 stainless steel wire mesh is highly corrosion-resistant.

321 stainless steel wire mesh is ideal for high-temperature applications and is highly resistant to corrosion. Understanding the differences between these grades can help you select the right material for your specific application.

4. Applications of stainless steel wire mesh

Stainless steel wire mesh is a versatile material that finds use in various industries due to its unique properties. Here’s an overview of some common applications of stainless steel wire mesh:

In Agriculture

Stainless steel wire mesh is used in agriculture for several purposes, such as animal containment, bird cages, and fencing. It can also be used as a substrate for hydroponic plant growth since it’s durable, corrosion-resistant, and allows water and nutrients to pass through.

In Construction

Stainless steel wire mesh is used in construction for reinforcing concrete structures, creating architectural meshes, and as a safety barrier on balconies and staircases. It can also be used as a decorative element in building facades, as it’s available in various weaves and aperture sizes.

In Transportation

Stainless steel wire mesh is commonly used in transportation for air filtration systems, fuel cell components, and engine parts. Its high strength-to-weight ratio makes it ideal for use in lightweight vehicles such as airplanes and boats.

In Food Processing

Stainless steel wire mesh is popular in the food processing industry due to its hygienic properties and corrosion resistance. It’s used for food strainers, screens, and filters, ensuring that food products remain free from contaminants. Stainless steel wire mesh is also used in commercial kitchens for oven racks, cooling racks, and baking trays.

Stainless steel wire mesh finds diverse applications across various industries, such as agriculture, construction, transportation, and food processing. Its exceptional properties, such as durability, corrosion-resistance, strength, and hygienic properties, make it an ideal choice for specialized applications.

Conclusion

In conclusion, understanding the different grades of stainless steel wire mesh is crucial to selecting the right material for your specific application. Each grade has its unique composition and properties, such as corrosion resistance, strength, and customizability, making them suitable for specialized applications.

By understanding the different grades of stainless steel wire mesh and their unique features, you can make an informed decision when selecting the ideal material for your needs, resulting in optimal performance, longevity, and cost-effectiveness.