Introduction

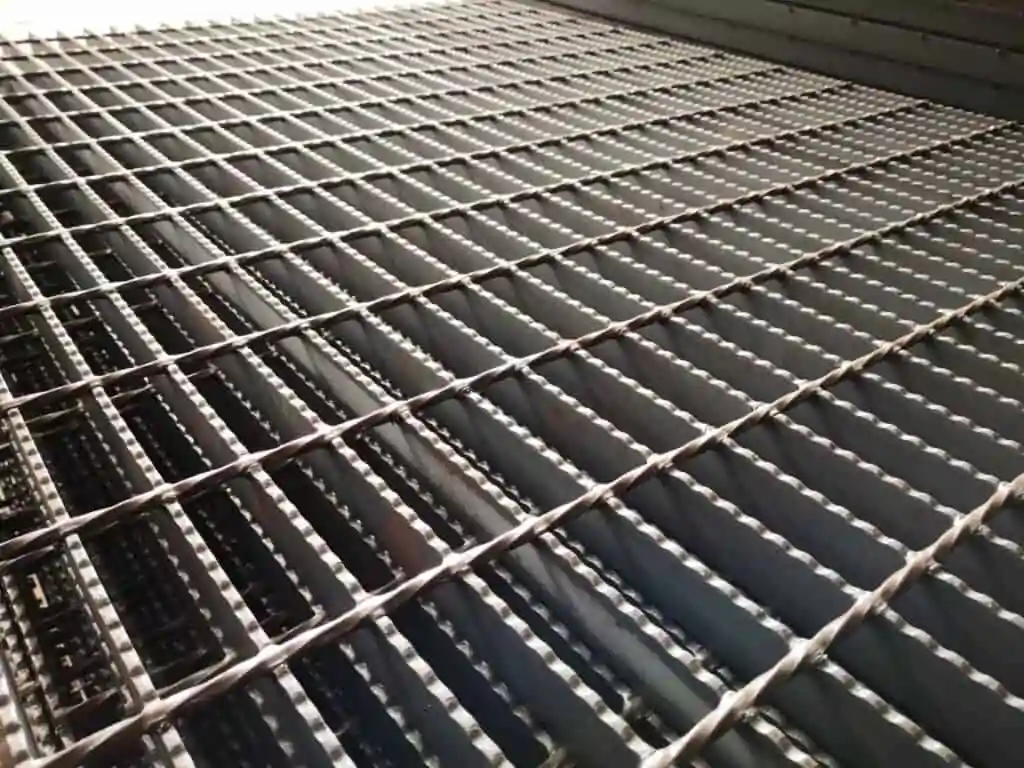

Carbon steel bar grating is a popular choice for walkways, platforms, and other structures where people need to walk

. It is strong and durable and can handle a lot of weight without bending or breaking.

In this blog post, we will discuss the different types of carbon steel bar grating, as well as some of its benefits and drawbacks.

We will also provide you with a few tips on how to choose the right carbon steel bar grating for your needs!

What Is Carbon Steel Bar Grating?

Carbon steel bar grating is a type of steel grating that is made from carbon steel. It is strong and durable, making it a popular choice for walkways, platforms, and other structures where people need to walk.

To Learn About These Companies In Detail Keep Reading.

What Is Carbon Steel Bar Grating And What Are Its Applications?

The term “carbon steel bar grating” refers to a type of steel grating that is made from carbon steel.

Also known as “press-locked bar grating” or “swage-locked bar grating,” this product is designed for applications where people need to walk.

There are many different types of carbon steel bar grating, each with its own set of benefits and drawbacks.

Some of the most common applications for carbon steel bar grating are given below:

· Walkways

· Platforms

· Drainage covers

· Stair treads

· Mezzanines

· Catwalks

· Workbenches

· Machinery guards

How Is Carbon Steel Bar Grating Manufactured?

The manufacturing process of carbon steel bar grating depends on the type of grating that you need.

For example, if you need a press-locked bar grating, the process will be different than if you need a swage-locked bar grating.

Below, here are step-by-step guides to the manufacturing process of carbon steel bar grating:

1. Cut Bars To Length:

The first step in the manufacturing process is to cut the bars to length. This is typically done with a power saw or a band saw.

It is important to make sure that the bars are cut to the correct length, as this will affect the overall fit and appearance of the grating.

2. Punch Holes In Bars:

The next step is to punch holes in the bars. This is done with a CNC machine or a punch press.

The holes are punched at regular intervals so that they line up with the connecting elements of the grating.

3. Insert Connecting Elements:

Another step is to insert the connecting elements into the holes. These elements can be made from a variety of materials, but most commonly they are made from stainless steel or aluminum.

4. Assemble The Grating:

Once all of the bars and connective elements are in place, the grating can be assembled. This is generally done by welding the pieces together, although other techniques such as riveting.

5. Finish The Grating:

The final step in the manufacturing process is to finish the grating.

This usually involves applying a coating of paint or powder to protect the grating from corrosion.

It is also common to add a nonslip surface to the grating, especially if it will be used in an area where people are walking.

The Different Types Of Carbon Steel Bar Grating!

There is a variety of different types of carbon steel bar grating, each with its own set of benefits and drawbacks. The six most common types are press-locked bar grating, swage-locked bar grating, and welded bar grating.

1. Press-Locked Bar Grating:

Press-locked bar grating is made by inserting connecting elements into holes that have been punched in the bars.

The bars are then pressed together, causing the connecting elements to lock the bars in place.

This type of grating is very strong and easy to install. However, it is not suitable for applications where there is a lot of vibration or movement.

2. Swage-Locked Bar Grating:

The swage-locked bar grating is similar to the press-locked bar grating, but the connecting elements are swaged (or crimped) into place instead of being pressed.

This makes the grating more resistant to vibration and movement.

So it is a good choice for applications where there is a lot of movement. It’s more difficult to install than press-locked bar grating.

3. Welded Bar Grating:

The welded bar is usually know as the best type of grating. It is made by welding the bars and connecting elements together.

Also, the ends of the bars are usually flared to help keep the grating in place. With welded bar grating, there are no separate parts to worry about losing or breaking.

And it is very strong and resistant to vibration and movement.

4. Riveted Bar Grating:

The riveted bar grating is similar to the welded bar grating, but the bars and connecting elements are riveted together instead of being welded.

If you need a grating that can withstand a lot of movement and vibration, then the riveted bar grating is a good choice.

It is also very strong and resistant to corrosion.

5. Aluminum Bar Grating:

If you need a grating that is lightweight and corrosion-resistant, then aluminum bar grating is a good choice. It is also non-magnetic and non-conductive.

This is not as strong as other types of grating and is not suitable for applications where there is a lot of movement or vibration.

If you are looking for an alternative to aluminum bar grating, then try fiberglass.

6. Fiberglass Bar Grating:

Fiberglass is a good choice of corrosion-resistant and non-conductive grating. With fiberglass, you don’t have to worry about it being affected by chemicals or high temperatures.

Also, it is very strong and can resist impact. The only downside is that it is not as easy to install as other types of grating.

The Benefits Of Using Carbon Steel Bar Grating!

Now that you know the different types of carbon steel bar grating, let’s take a look at some of the benefits of using it. Below here are a few benefits of using it:

1. Support A Lot Of Weight:

The first benefit is that it can support a lot of weight. This is because the bars are welded or riveted together, making it very strong.

Also, the bars are usually made from high-quality steel, which is very strong and can support a lot of weight.

2. Resistant To Corrosion:

The second benefit is that it is resistant to corrosion. This is because most bars are coated with a powder coating, which protects them from rust and corrosion…

Also, the connecting elements are made from stainless steel, which is also resistant to corrosion.

3. Non-Conductive:

Another benefit is that it is non-conductive. It comes in handy in environments where there is a lot of electrical equipment. It will not conduct electricity, which can cause a fire or explosion.

4. Non-Magnetic:

Non-magnetic is another benefit of using it. With this type of grating, you don’t have to worry about it being affected by magnets.

This is because the bars are made from aluminum, which is not magnetic.

5. Lightweight:

The last benefit is that it is lightweight. You can easily install it without the need for heavy machinery. So if you need a grating that is easy to install, then this is the type you need.

There are many benefits of using carbon steel bar grating. But these are just some of the most important ones. If you need a grating that is strong, corrosion-resistant, and easy to install, then carbon steel bar grating is the way to go.

Installation Tips For Carbon Steel Bar Grating!

Before you start the installation process, there are a few things you need to know.

1. Make Sure The Surface Is Level:

The first thing you need to do is to make sure the surface is level. If the surface is not level, the grating will not be level either.

And if the grating is not level, then it can cause problems such as water pooling on top of it or people trip over it.

2. Measure The Area:

If you want to install the grating yourself, then you need to measure the area first. You need to know how much grating you need to buy.

When you don’t measure the area, then you might end up buying too much or too little grating.

3. Cut The Grating To Size:

Cut the grating to size using a grinder or a saw. Make sure that the cuts are straight and even. If the cuts are not straight, then the grating will not fit properly.

4. Install The Grating:

Now it’s time to install the grating. There are two ways to do this.

The first way is to weld the grating to the surface. The second way is to bolt the grating to the surface.

We recommend that you bolt the grating to the surface because it is easier and faster.

5. Check For Leaks:

Once you have installed the grating, you need to check for leaks. This is important because if there are leaks, then water can get into the grating and cause problems.

These are just some tips on how to install carbon steel bar grating. If you follow these tips, then you will be able to install it properly.

Care And Maintenance Of Carbon Steel Bar Grating!

The last thing you need to know is how to care for it. We will provide you some tips on how to care for your grating.

1. Clean It Regularly:

The first thing you need to do is to clean it regularly. You need to remove all the dirt, dust, and debris from the surface. If you don’t clean it regularly, then the dirt and dust will build up and even damage the surface.

2. Inspect It Regularly:

Inspect it regularly for any signs of damage. If you see any damage, then you need to repair it immediately. When you don’t repair it, then the damage will get worse and eventually lead to the grating being replaced.

3. Protect It From The Sun:

The sun can damage the grating. So you need to protect it from the sun. You can do this by putting a tarp over it when it is not in use.

4. Protect It From The Rain:

With this type of grating, you need to be careful with the rain. If the rain gets into the grating, then it can cause rust. Then the grating will be damaged and will need to be replaced.

5. Store It Properly:

When you are not using the grating, and when you want to store it, then store it in a dry place. If you store it in a wet place, then it can get damaged.

Conclusion

Carbon steel bar grating is a popular material choice for a variety of projects. It is strong, durable, and can be used in many different applications.

If you are considering using carbon steel bar grating in your next project, be sure to consult with a professional to get the best advice on the right type and grade of grating for your needs.

SUNJ GRATING LIMITED is here to help with all of your carbon steel bar grating needs. Contact us today for more information!