Introduction

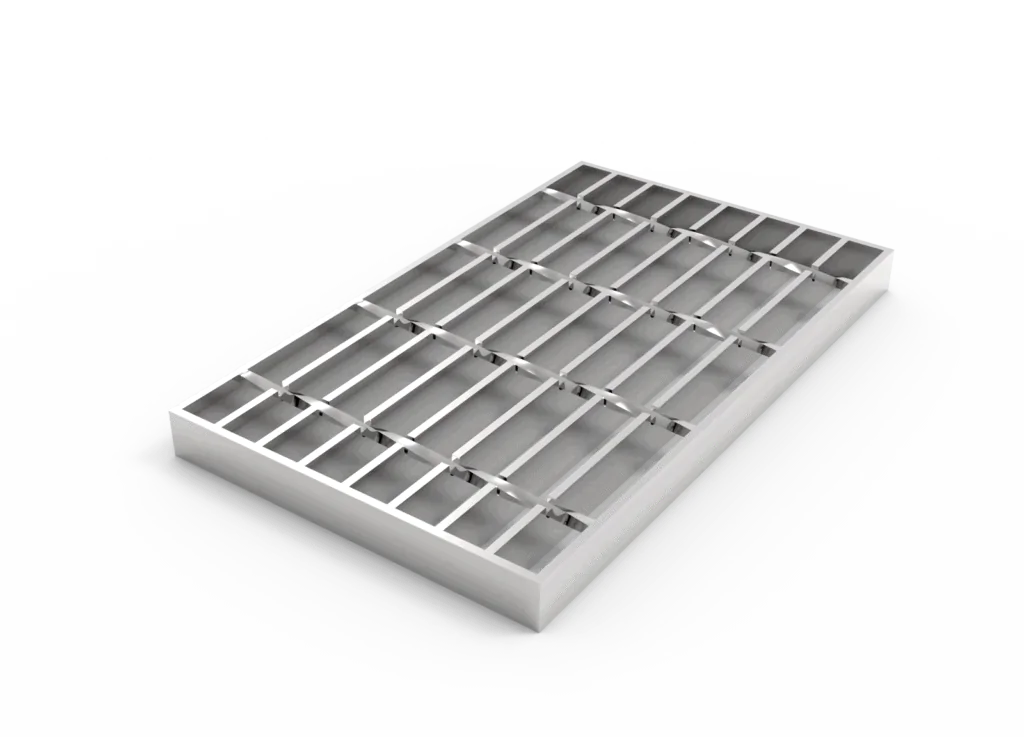

If you are looking for a durable and safe flooring solution, 316 stainless steel grating might be the perfect option for you.

This type of grating is made from high-quality stainless steel, which makes it resistant to corrosion and wear.

It is also non-slip, making it a great choice for areas where safety is a top priority. In this blog post, we will discuss the benefits of 316 stainless steel grating and how it can be used in a variety of applications.

What Is 316 Stainless Steel Grating?

316 stainless steel grating is a type of metal grating made from high-quality stainless steel. It is strong and durable, making it an ideal choice for a variety of applications.

To Learn About These Companies In Detail Keep Reading.

316 Stainless Steel Grating Is A Great Choice For Durable, Safe Flooring!

316 stainless steel grating is a great choice for durable, safe flooring because it is slip-resistant and has a high resistance to corrosion and wear.

It is also non-slip, making it a great choice for areas where safety is a top priority.

When choosing a grating material, it is important to consider the environment in which it will be used and the level of traffic that it will encounter.

316 stainless steel grating is a great choice for both indoor and outdoor applications. 316 stainless steel grating can be used in a variety of applications, including:

Applications:

· Commercial kitchens

· Food processing plants

· Hospitals

· Pharmaceutical factories

· Airports

· Swimming pools

· Outdoor walkways

It’s Corrosion-Resistant And Perfect For Wet Or Humid Environments!

The durability of 316 stainless steel grating makes it an ideal choice for areas that are exposed to high traffic or corrosive elements.

It is perfect for environments that are wet or humid, such as commercial kitchens, food processing plants, and hospitals.

1. Take A Look At The Environment:

The first thing you need to do is take a look at the environment where the 316 stainless steel grating will be used. Consider the level of traffic and exposure to corrosive elements.

2. Determine The Type Of Grating:

There are two types of stainless steel gratings- welded and pressure locked. Welded gratings are made by welding the bearing bars and cross bars together.

Pressure-locked gratings are made by locking the cross bars into the bearing bars under high pressure.

3. Select The Finish:

The next step is to select the finish of the grating. The most common finish is mill finish, which is a smooth, Satin-like finish. There are also other finishes available, such as polished and brushed.

4. Choose The Right Size:

When choosing the size of the grating, it is important to consider the environment and the level of traffic. For example, if the grating will be used in a high-traffic area, you will need to choose a larger size.

5. Consider The Weight:

The weight of the grating is another important factor to consider. If the grating will be used in an area where there is a lot of traffic, you will need to choose a heavier-duty grating.

The Open Construction Allows Liquids And Debris To Flow Through Easily, Making It Ideal For Industrial And Commercial Settings!

Hence, the open construction of 316 stainless steel grating allows liquids and debris to flow through easily, making it ideal for industrial and commercial settings.

In addition, the high resistance to corrosion and wear makes it an ideal choice for outdoor applications. Here are a few steps making it ideal for industrial and commercial settings:

1. Look For A Grating That Is Made Of High-Quality Stainless Steel:

The first step is to look for a grating that is made of high-quality stainless steel. This will ensure that the grating is durable and resistant to corrosion and wear.

2. Choose A Grating With An Open Construction:

The next step is to select a grate with an open construction. It allows liquids and debris to flow through easily, making it ideal for industrial and commercial settings.

3. Select A Grating That Is The Right Size For The Area:

When choosing the grating, it is important to select the right size for the area. If the grating is too small, it will not be able to handle the traffic. If the grating is too large, it will take up too much space.

4. Choose A Grating That Is Easy To Install:

The last step is to choose a grating that is easy to install. It helps you save time and effort during installation.

316 Stainless Steel Grating Is Also Slip-Resistant, Ensuring That Workers And Visitors Stay Safe On Your Property!

In addition, the 316 stainless steel grating is also slip-resistant, ensuring that workers and visitors stay safe on your property.

The slip-resistant surface is ideal for areas that are wet or oily. Here are a few tips to choose the right slip-resistant grating for your property:

1. Consider The Environment:

The first thing you need to do is take a look at the environment where the grating will be used. Consider the level of traffic and exposure to corrosive elements.

2. Select The Right Material:

There are a variety of slip-resistant materials available, such as stainless steel and aluminum. Choose the material that is best suited for the environment.

3. Consider The Size:

The next thing to consider is the size of the grating. Choose a size that is appropriate for the area.

4. Install The Grating Properly:

Once you have selected the grating, it is important to install it properly. If the grating is not installed correctly, it will not be able to provide the slip-resistant surface you need.

The Non-Slip Surface Ensures Safety For Both People And Equipment!

The non-slip surface of the grating is important for both people and equipment. The non-slip surface provides traction and prevents slips and falls.

The non-slip surface helps to protect equipment from being damaged. Here are a few tips to ensure safety for both people and equipment:

1. Inspect The Grating Regularly:

The first step is to inspect the grating regularly. Look for any signs of wear or damage.

2. Clean The Grating Regularly:

The next step is to clean the grating regularly. This will help to remove any dirt or debris that could cause slipping.

3. Choose The Right Grating For The Environment:

When choosing the grating, it is important to select the right one for the environment. Consider the level of traffic and exposure to corrosive elements.

Installation Is Quick And Easy, Making It A Great Choice For Busy Environments!

If you’re short on time and need a solution that won’t take long to implement, go with a grating. The installation process is simple and does not require special tools or equipment.

Here are some tips to help you install the grating quickly and easily:

1. Read The Instructions:

The first step is to read the instructions. This will help you understand the installation process and what you need to do.

2. Prepare The Area:

The next step is to prepare the area where the grating will be installed. Make sure that the area is clean and free of debris.

3. Place The Grating:

You should place the grating in the prepared area. Level and secure the grating, as shown above. Furthermore, please ensure that the grating is an appropriate size for the space.

4. Install The Supports:

The next step is to install the supports. It helps to keep the grating in place and prevent it from moving.

5. Finish The Installation:

The last step is to finish the installation. This includes adding any finishing touches, such as trimming the grating.

Grating Can Be Used In A Variety Of Settings, Including Factories, Warehouses, And Schools!

Let’s take a closer look at variety of setting in which grating can be used. Below we discuss some of the different places where grating can be used:

1. Factory Settings:

Grating can be used in a variety of factory settings. The grating can be used to create workstations, as well as to create a safe environment for workers.

2. Warehouse Settings:

The warehouse is not the only setting in which the grating can be used. The grating can help to create a safe and efficient working environment.

So, if you’re looking for a way to improve the safety and efficiency of your warehouse, grating is a great option.

3. School Settings:

Grating can also use in school settings. The grating can provide a safe and pleasant learning environment for students.

4. Retail Settings:

The grating can apply to retail settings as well. The grating may assist in the creation of a secure and attractive shopping environment for consumers.

5. Office Settings:

The grating may also be utilized in the workplace. The grating presents many advantages for employers who want to create a safe and productive workplace for their employees.

6. Outdoor Settings:

Not only can this grating be used indoors, but it is durable enough to withstand outdoor conditions. The grating may use to make a safer and more pleasant environment for people.

Conclusion

316 stainless steel gratings are a great choice for many applications. They have a high resistance to corrosion and can be used in both indoor and outdoor settings.

When choosing a grate, it is important to consider the load-bearing capacity, his type of surface finish desired, and the environment in which it will be used.

SUNJ GRATING LIMITED offers a wide range of 316 stainless steel gratings that can meet your needs.

We also provide custom fabrication services to ensure that you get a grate that is perfect for your application. Contact us today to learn more about our products and services!