Introduction

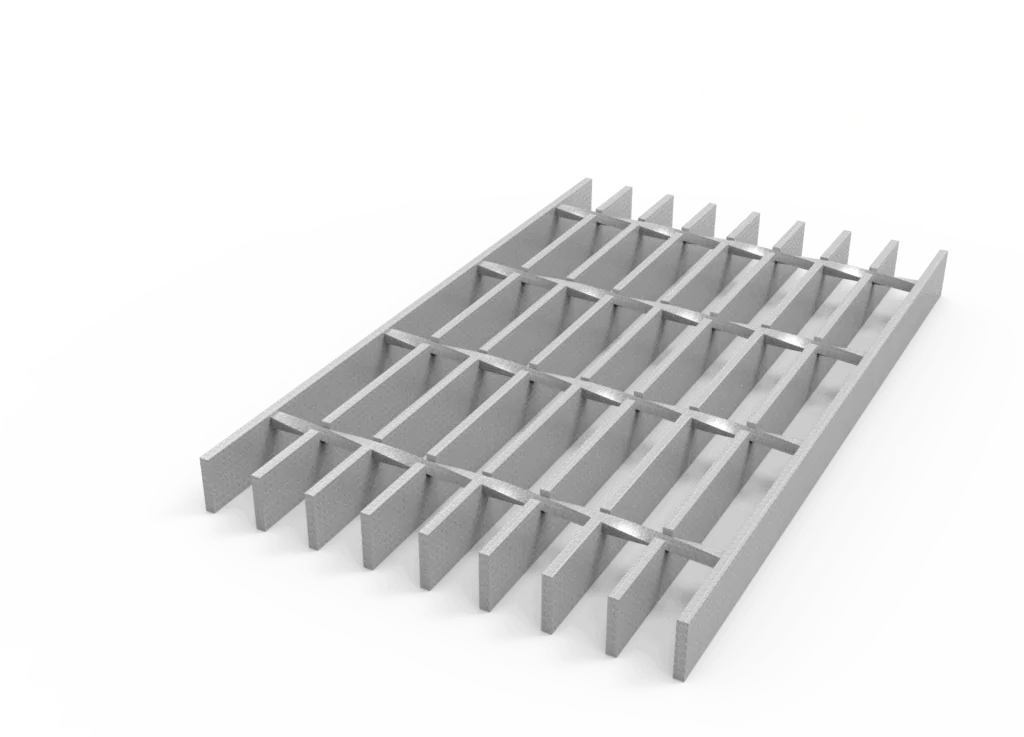

19 w 4 steel bars grating is a type of grating that is made from 19-w 4 steel.

It is often used in industrial and commercial applications, as it is durable and has a high load-bearing capacity.

19 w 4 steel bars grating is available in a variety of sizes and can be custom-made to meet the specific needs of any project.

It is easy to install and comes in either a welded or press-locked construction. 19 w 4 steel bars grating is an economical choice for many industrial and commercial applications.

Why 19 W 4 Steel Bar Grating An Ideal Choice For Many Industrial And Commercial?

19 W 4 steel bar grating is a popular option for industrial and commercial uses due to its strength and high load-bearing capacity.

For More Information Keep Reading This Blog Post!

What Is 19-W-4 Steel Bar Grating And What Are Its Uses?

A type of grating made from 19-w 4 steel is known as a bar grating.

It’s frequently utilized in industrial and commercial settings since it’s sturdy and has a high load-bearing capacity.

The 19 w 4 steel bars grating are available in various sizes and can be custom-made to fit the specific requirements of each project. Let’s take a look at some of the most common uses for 19-w 4 steel bar grating:

1. Industrial Uses:

The durability of 19-w-4 steel bar grating makes it an ideal choice for many industrial applications. It can be used in a variety of settings, such as factories, warehouses, and other industrial buildings.

2. Commercial Uses:

19-w-4 steel bar grating can also be used in a number of commercial settings, such as shopping malls, office buildings, and other structures.

With its high load-bearing capacity, it can easily accommodate the heavy foot traffic that these settings typically experience.

3. Sewage And Water Treatment Plants:

19-w-4 steel bar grating is often used in sewage and water treatment plants. It is resistant to corrosion and can withstand the harsh chemicals used in these environments.

4. Food Processing Plants:

The food processing industry also relies on 19-w-4 steel bar grating. There are numerous applications in this industry, such as in meatpacking plants, dairies, and other food processing facilities.

5. Marine Environments:

The final use that we’ll mention is in marine environments. If you are in need of grating for a marina, docks, or other similar applications, 19-w-4 steel bar grating is an excellent choice.

It is resistant to corrosion and can withstand the salty air and water.

There are many other uses for 19-w-4 steel bar grating. These are just a few of the most common applications. If you have a project that requires grating, this is an excellent option to consider.

How To Select The Right Type Of Grating For Your Needs?

Selecting the right type of grating for your needs can seem like a daunting task, but it doesn’t have to be. Follow the easy steps below and you’ll be on your way to choosing the perfect grating for your project.

1. Determine The Load-Bearing Requirements.

The first step is to determine the load-bearing requirements of your project. This helps you narrow down your options and choose a grating that is able to support the weight of whatever will be placed on it.

2. Consider The Environment.

The next stage is to think about the environment in which the grating will be used.

This is important because you’ll need to choose a grating that can withstand the specific conditions of the environment.

For example, if the grating will be used in a marine setting, you’ll need to choose one that is resistant to corrosion.

3. Select The Right Material.

Once you’ve considered the load-bearing requirements and the environment, you can start to narrow down your choices by selecting the right material.

There are a variety of materials to choose from, such as stainless steel, aluminum, and more.

4. Choose The Right Size.

Choosing the correct size grating is vital for your project’s success. Gratings come in a variety of sizes, so you should select one that is able to accommodate the area you have available.

5. Consider The Finish.

The final step is to consider the finish of the grating. You’ll want to choose a grating that has a finish that is able to withstand the conditions of the environment.

For example, if the grating will be used in a marine setting, you’ll want to choose one that has a corrosion-resistant finish.

Now that you know how to select the right type of grating for your needs, you’re one step closer to completing your project.

The Benefits Of Using Grating In Industrial And Commercial Settings!

Now that we’ve gone over how to select the right type of grating for your needs, let’s take a look at some of the benefits of using grating in industrial and commercial settings.

1. Grating Is Strong And Durable.

One of the main benefits of using grating is that it is strong and durable. Grating is typically made from steel or another similarly tough material.

This is because it’s waterproof and anti-corrosive, which makes it perfect for use in industrial and commercial areas.

2. Grating Is Slip-Resistant.

Grating is also slip-resistant, which means it’s less likely to cause accidents. This is due to the fact that grating has a raised surface.

This raised surface provides traction and prevents slips and falls.

3. Grating Is Easy To Install.

Benefits of grating include ease of installation. Time-saving qualities make this an ideal choice for projects.

4. Grating Is Low-Maintenance.

Grating is low-maintenance and has several additional advantages. Once grating is installed, it doesn’t require much maintenance.

The versatility and low cost of this product makes it an excellent choice for busy industrial and commercial spaces.

5. Grating Is Versatile.

Finally, grating is versatile. This implies that it can be used in a variety of situations and for a variety of purposes. No matter what your needs are but grating is a good option for you.

Installation Tips And Advice!

In this section, we’ll provide some tips and advice on how to install grating. Below are a few steps to take during the installation process:

1. Plan The Installation.

The first step is to plan the installation. This means having a clear understanding of the area where the grating will be installed. You’ll need to take measurements and determine the best way to install the grating.

2. Prepare The Area.

Now that you have your grating, it’s time to prepare the area where it will be installed. It also implies cleaning the surface and checking for any obstructions.

3. Lay Out The Grating.

The third step is to lay out the grating. This can be done by measuring and cutting the wood to size, then nailing or screwing it into place. It means placing the grating in the desired location and making sure it is level.

4. Secure The Grating.

The fourth step is to secure the grating. The grating is held in place with screws, bolts, or another type of fastener.

5. Finish The Installation.

The final step is to finish the installation. In most cases, this means adding any trim or molding to cover the edges of the grating. This gives the project a polished look and protects the grating from damage.

Maintenance Tips To Keep Your Grating Looking Great For Years To Come!

The best way to keep your grating looking great for years to come is to perform regular maintenance. Below are a few tips on how to maintain your grating:

1. Check for damage so that you can repair it. You should check your grating regularly for any damage. If you find any, you should repair them as soon as possible.

2. Keep the grating clean. You can also keep the grating clean. This can be done by sweeping it regularly and removing any dirt or debris.

3. Remove any rust. Rust can damage grating, so you can remove it as soon as possible. You can use a rust remover or sandpaper to remove rust.

4. Apply a coat of paint. Paint can help protect grating from damage. You should apply a coat of paint every few years.

5. Don’t use harsh chemicals. You need to avoid using harsh chemicals on grating. This can damage the finish.

6. Don’t walk on grating. Grating is not designed to be walked on. Walking on it can damage the grating and make it more likely to break.

7. Store grating properly. When you’re not using grating, you should store it properly. It will protect it from damage.

By following these tips, you can help to keep your grating looking great for years to come. Regular maintenance will help to prolong the life of your grating.

FAQs About The 19-W-4 Steel Bar Grating!

Q: Why Should I Choose 19-W-4 Steel Bar Grating?

A: There are several reasons why you should choose 19-w-4 steel bar grating. First, it is strong and durable. Second, it is easy to install.

Third, it is low maintenance. Fourth, it is versatile. Fifth, it is attractive. All of these reasons make 19-w-4 steel bar grating a good choice for your project.

Q: What Are The Dimensions Of 19-W-4 Steel Bar Grating?

A: The dimensions of 19-w-4 steel bar grating are 3/16″ x 1-1/2″ x 19-W-4.

Q: How Much Does 19-W-4 Steel Bar Grating Weigh?

A: 19-w-4 steel bar grating weighs approximately 1.45 pounds per square foot.

Q: How Is 19-W-4 Steel Bar Grating Made?

A: 19-w-4 steel bar grating is made by welding steel bars together. The steel bars are then placed in a machine that cuts them to the correct size and shape.

Conclusion

We hope that this comprehensive guide has helped you understand everything there is to know about steel bar grating.

With so many different types and applications, it can be difficult to decide which product is right for your needs.

If you are still unsure after reading this guide, or if you have any specific questions, please do not hesitate to contact our team of experts.

We would be happy to help you find the perfect steel bar grating solution for your project. Thank you for choosing Chinasteelgrating as your source for quality metal products.