Introduction

Expanded metal wire mesh is a versatile material that can be used in a wide range of applications. From building construction to industrial manufacturing, this material has a unique set of properties that make it stand out from other types of wire mesh.

In this article, we’ll explore four diverse uses of expanded metal wire mesh and showcase the benefits of using this material in each application. Whether you’re a contractor, an architect, or just curious about innovative materials, read on to discover how expanded metal wire mesh can be utilized in unexpected and creative ways.

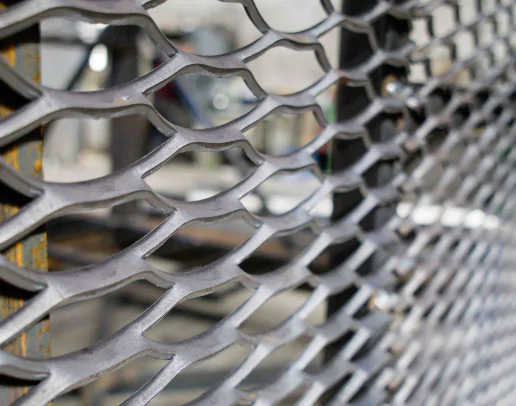

1. What is expanded metal wire mesh

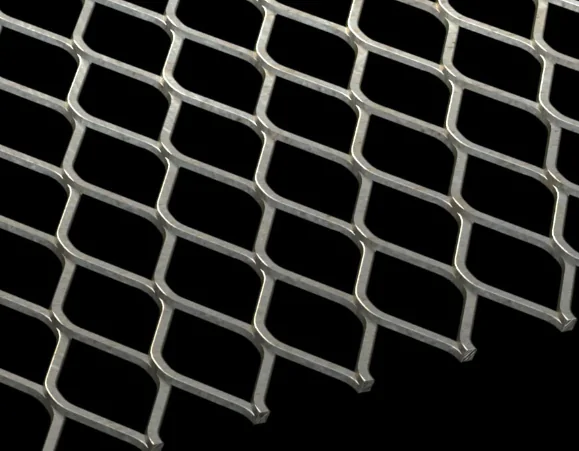

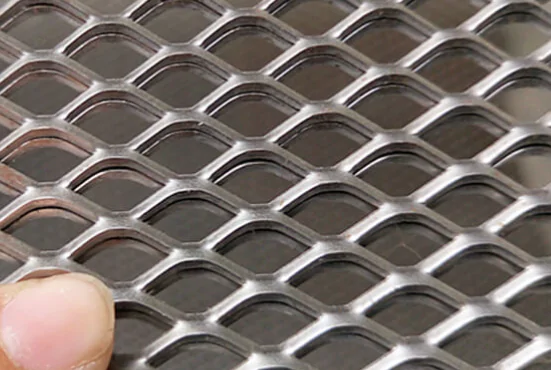

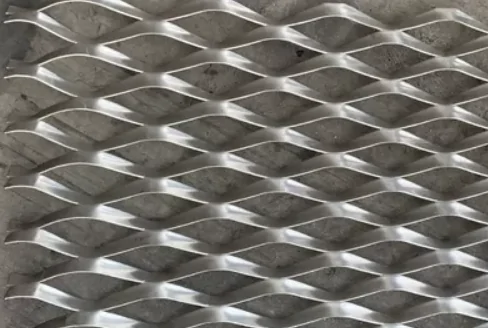

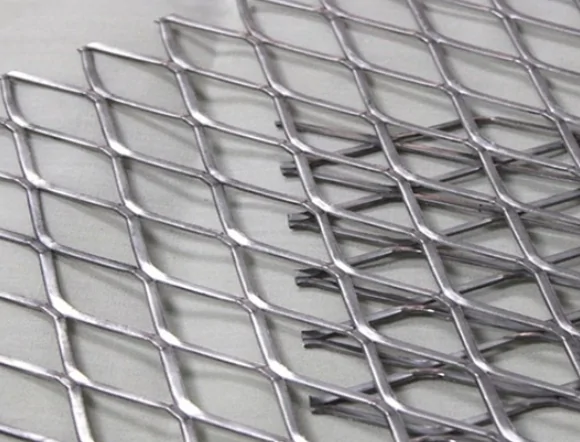

Expanded metal wire mesh is a type of mesh that is created by stretching and slitting a sheet of metal, such as aluminum or steel. The process involves cutting and expanding the metal to create a pattern of diamond-shaped openings, which are then flattened to form a sheet.

One of the main characteristics of expanded metal wire mesh is its strength and durability. Due to its unique manufacturing process, the metal is able to maintain its structural integrity while still being flexible enough to be shaped into various forms. This makes it an ideal material for a wide range of applications, including fencing, grating, and screening.

Another key feature of expanded metal wire mesh is its versatility. It can be easily cut, bent, and formed into different shapes and sizes, making it adaptable to a variety of needs. Additionally, the diamond-shaped openings in the mesh allow for excellent ventilation and light transmission, while still providing a secure barrier.

Overall, expanded metal wire mesh is a reliable and practical choice for anyone seeking a strong and versatile material for their building or construction needs.

2. Brief history and development

The history of expanded metal wire mesh dates back to the 19th century, when it was first developed as a way to create lightweight yet durable fencing and grating materials for industrial applications.

The process of expanding metal sheets was originally developed in England in the mid-1800s. The first machines used for this purpose were simple hand-operated devices that punched holes into metal sheets and then stretched them to create a mesh-like pattern.

In the early 1900s, more advanced machinery was developed that allowed for faster and more efficient production of expanded metal wire mesh. This led to the widespread use of the material in various industries, including construction, automotive manufacturing, and aerospace engineering.

During World War II, expanded metal wire mesh played an important role in military applications. It was used to create protective barriers, filters, and other essential components for aircraft engines and tanks.

In the decades that followed, expanded metal wire mesh continued to evolve as new materials and technologies were developed. Today, it is available in a wide range of sizes, shapes, and materials, making it a versatile and popular option for a variety of industrial and architectural applications.

3. Uses in Construction

Expanded metal wire mesh has several important uses in construction due to its strength, durability, and versatility. Three of the most common uses for expanded metal wire mesh in construction are as follows:

Reinforcement for concrete structures

Expanded metal wire mesh is often used as reinforcement for concrete structures such as walls, foundations, and columns. The mesh is embedded within the concrete to provide additional tensile strength, helping to support the weight of the structure and prevent cracking or collapse.

Cladding and facades for buildings

Expanded metal wire mesh can also be used as cladding or facade material for buildings. The mesh can be cut, shaped, and formed into a variety of patterns and designs, providing an eye-catching and contemporary finish.

In addition, the diamond-shaped openings in the mesh allow for ventilation and light transmission while still maintaining privacy and security.

Security fencing for construction sites

Expanded metal wire mesh is frequently used as security fencing for construction sites due to its strength and durability. The mesh panels can be easily installed and provide a strong barrier that is difficult to breach, helping to protect workers and materials on site.

Expanded metal wire mesh is a highly versatile material with a wide range of uses in construction. Its strength, durability, and ability to be shaped and formed make it an ideal choice for a variety of applications, from reinforced concrete structures to providing secure fencing for construction sites.

4. Uses in Agriculture

Expanded metal wire mesh is a popular material in agriculture due to its strength, durability, and ability to provide protection for crops and animals. Three of the most common uses for expanded metal wire mesh in agriculture are as follows:

Animal enclosures and cages

Expanded metal wire mesh can be used to create animal enclosures and cages for a variety of animals such as chickens, rabbits, and goats. The mesh panels provide a secure and durable enclosure that prevents predators from getting in and animals from getting out.

Pest control and prevention

Expanded metal wire mesh can also be used for pest control and prevention. The mesh can be used to cover vents and other openings to prevent pests from entering buildings or to create barriers around crops to prevent damage from insects and rodents.

Crop protection and support

Expanded metal wire mesh can be used to provide support for plants such as tomatoes, beans, and peas. The mesh can also be used to create protective barriers around crops to prevent damage from animals or weather conditions.

Expanded metal wire mesh is a versatile material that provides protection and support for a wide range of agricultural applications. Its strength, durability, and resistance to pests make it an ideal choice for animal enclosures, pest control, and crop protection.

5. Uses in the Industrial Sector

Expanded metal wire mesh is widely used in the industrial sector due to its strength, durability, and versatility. Three of the most common uses for expanded metal wire mesh in this sector are as follows:

Filtration and separation: Expanded metal wire mesh is frequently used for filtration and separation applications in industries such as oil and gas, chemical processing, and water treatment. The mesh can be formed into various shapes and sizes to filter out impurities from liquids and gases.

Safety grating for industrial floorings: Expanded metal wire mesh can be used as safety grating for industrial flooring. The mesh panels provide a slip-resistant surface that helps prevent accidents and injuries in industrial settings such as factories, warehouses, and manufacturing plants.

Machine guards and protective barriers: Expanded metal wire mesh can also be used to create machine guards and protective barriers for industrial machinery. The mesh panels provide a strong and durable barrier that protects workers from moving parts and other potential hazards.

Expanded metal wire mesh is a highly versatile material that finds many uses in the industrial sector. Its strength, durability, and ability to be shaped and formed make it an ideal choice for filtration and separation, safety grating for flooring, machine guards, and protective barriers.

6. Uses in Creativity and Decoration

Expanded metal wire mesh has numerous decorative and creative uses due to its unique texture and pattern. Three of the most common uses for expanded metal wire mesh in creativity and decoration are as follows:

Artistic installations and sculptures

Expanded metal wire mesh can be used to create unique and visually striking artistic installations and sculptures. The mesh panels can be formed into various shapes and sizes, providing endless possibilities for artistic expression.

Interior design elements

Expanded metal wire mesh can be incorporated into interior design elements such as room dividers, wall cladding, and light fixtures. The mesh panels provide a modern and industrial look that is popular in contemporary interior design.

Customized furniture and fixtures

Expanded metal wire mesh can also be used to create customized furniture and fixtures such as chairs, tables, and shelving units. The mesh panels can be cut and formed to fit specific designs, providing a one-of-a-kind look for any space.

Expanded metal wire mesh is a highly versatile material that can add a unique and modern touch to any creative or decorative project. Its ability to be shaped and formed into various designs makes it an ideal choice for artistic installations and sculptures, interior design elements, and customized furniture and fixtures.

7. Advantages of Expanded Metal Wire Mesh

Expanded metal wire mesh has several advantages that make it a popular choice in a variety of applications. Here are four key advantages of expanded metal wire mesh:

- Durability and strength: Expanded metal wire mesh is highly durable and resistant to wear and tear. Its unique diamond-shaped pattern provides added strength and stability, making it an ideal material for applications where strength and durability are important.

- Lightweight and easy to install: Despite its strength and durability, expanded metal wire mesh is relatively lightweight and easy to install. This makes it a popular choice for applications where weight is a concern, such as in aircraft and automotive manufacturing.

- Versatile and customizable: Expanded metal wire mesh is available in a wide range of sizes, shapes, and materials, making it highly versatile and customizable to fit a variety of needs. It can be cut, bent, and formed to fit specific designs, providing endless possibilities for creative expression.

- Cost-effective: Compared to other materials such as solid metal sheets or woven wire mesh, expanded metal wire mesh is often more cost-effective due to its efficient manufacturing process. Additionally, its durability and resistance to wear and tear make it a long-lasting and cost-effective choice for many applications.

Overall, expanded metal wire mesh offers several advantages, including durability and strength, lightweight and easy installation, versatility and customization, and cost-effectiveness.

Conclusion

In conclusion, expanded metal wire mesh is a highly versatile material that finds diverse applications across various industries.

From reinforcing concrete structures to creating unique art installations and sculptures, expanded metal wire mesh offers several advantages such as durability, strength, lightweight, versatility, customizability, and cost-effectiveness. As new materials and technologies continue to emerge, the potential uses of expanded metal wire mesh in different industries will only continue to expand.